-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 11, 2025 08:20 Back to list

Premium Expanded Metal Mesh Sheets | Custom & Wholesale Factory

Introduction to Expanded Metal Mesh

In industrial engineering and architectural design, the demand for versatile, durable, and cost-effective materials is paramount. Expanded metal mesh stands out as a material offering exceptional strength-to-weight ratio, superior ventilation, and inherent safety features. Unlike woven or welded alternatives, this material is formed from a single piece of metal, ensuring structural integrity without welds or interlocks. This unique manufacturing process grants it remarkable adaptability for diverse applications, from high-security fencing to advanced filtration systems and robust architectural facades. Its inherent properties make it indispensable across a spectrum of industries requiring reliable, long-lasting solutions.

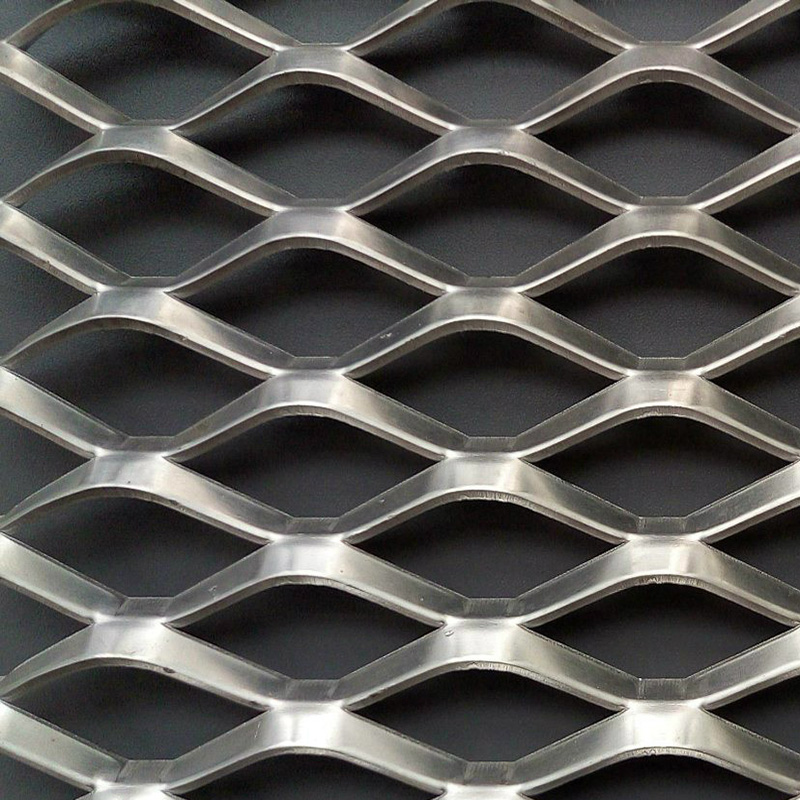

The production of a expanded metal mesh sheet involves a precise slitting and stretching process, which transforms solid metal plates into a lattice of uniform, diamond-shaped openings. This process not only minimizes material waste but also enhances the material's rigidity and load-bearing capabilities. The result is a product that is lighter than solid plate, yet incredibly strong, making it ideal for applications where both performance and material efficiency are critical. Its open design also facilitates excellent air, light, and fluid passage, which is crucial for many industrial and commercial uses.

Manufacturing Process: From Raw Material to Finished Product

The production of expanded metal mesh is a sophisticated cold-forming process that significantly enhances the material’s structural properties without generating waste from punching or cutting out material. This efficiency contributes to both environmental sustainability and cost-effectiveness.

Key Materials:

- Carbon Steel: Widely used for general industrial applications due to its strength and economic efficiency. Can be galvanized for enhanced corrosion resistance.

- Stainless Steel (e.g., 304, 316): Offers superior corrosion resistance, high temperature tolerance, and aesthetic appeal, ideal for marine, chemical, and food processing industries.

- Aluminum: Lightweight, corrosion-resistant, and excellent for architectural and transportation applications where weight is a critical factor.

- Special Alloys: Such as Monel, Inconel, or Titanium, used for highly specialized applications requiring extreme chemical resistance or strength.

Manufacturing Process Steps:

- Galvanization: Hot-dip galvanizing adds a protective zinc coating for superior corrosion resistance, crucial for outdoor and harsh environments.

- Powder Coating: Applies a durable, decorative, and protective finish available in a wide range of colors, ideal for architectural or aesthetic applications, producing powder coated expanded metal mesh.

- Anodizing: For aluminum mesh, enhancing corrosion resistance and surface hardness.

- Painting: For specific color requirements or additional protection.

Figure 1: Illustration of expanded metal mesh manufacturing stages.

Quality Control & Testing Standards:

Adherence to international standards is critical for ensuring the performance and longevity of expanded metal mesh. Our products are manufactured and tested in compliance with stringent industry benchmarks.

- ASTM F1267: Standard Specification for Metal, Expanded, Steel, for Fencing and Security Mesh.

- ISO 9001:2015: Quality Management Systems certification ensures consistent product quality and process efficiency.

- ANSI/NAAMM MBG 531-09: Metal Bar Grating Manual, which often contains relevant specifications for mesh-like products.

- Material Composition Analysis: Spectroscopic analysis to verify alloy specifications.

- Dimensional Accuracy: Regular checks of LWD (Long Way of Design), SWD (Short Way of Design), strand width, and thickness.

- Tensile Strength & Yield Strength: Mechanical property testing to confirm load-bearing capabilities.

- Corrosion Resistance Testing: Salt spray tests for galvanized or powder coated expanded metal mesh to assess protective coating effectiveness.

With proper material selection and appropriate finishing, the service life of a high-quality expanded metal mesh can exceed 20-30 years, even in challenging industrial environments.

Technical Specifications and Parameters

Understanding the technical specifications of expanded metal mesh is crucial for engineers and procurement specialists to ensure optimal material selection for specific applications. Key parameters define the mesh's structural integrity, open area, and suitability.

Standard Expanded Metal Mesh Sheet Parameters:

| Parameter | Description | Typical Range | Unit |

|---|---|---|---|

| Long Way of Design (LWD) | The distance from the center of the bond to the center of the bond along the longer dimension of the diamond. | 12.7 to 150 | mm |

| Short Way of Design (SWD) | The distance from the center of the bond to the center of the bond along the shorter dimension of the diamond. | 6 to 75 | mm |

| Strand Width | The amount of metal fed through the expanding machine to produce one strand. | 0.5 to 8 | mm |

| Thickness (Gauge) | The original thickness of the metal sheet from which the mesh is expanded. | 0.5 to 6 | mm |

| Overall Thickness | The measured thickness from top surface to bottom surface of the mesh (for standard, non-flattened mesh). | 1 to 10 | mm |

| Open Area Percentage | The percentage of the total surface area that is open (allowing passage of air, light, fluid). | 40 to 85 | % |

| Weight | Weight per unit area, dependent on material, strand width, and mesh pattern. | 1 to 30 | kg/m² |

These parameters are critical for engineers designing systems where flow rates, filtration efficacy, structural load, or aesthetic appearance are paramount. Custom dimensions and specifications are routinely produced to meet unique project requirements, making a custom expanded metal mesh a highly flexible solution.

Figure 2: Close-up of expanded metal mesh texture and structure.

Comparison: Standard vs. Flat Expanded Metal Mesh:

| Feature | Standard (Raised) Expanded Metal Mesh | Flat Expanded Metal Mesh |

|---|---|---|

| Surface | Ribbed, corrugated, with strands and bonds set at an angle to the plane of the sheet. | Smooth, flat, uniform surface, created by cold-rolling. |

| Thickness | Overall thickness is greater than the original material thickness. | Overall thickness is close to the original material thickness. |

| Rigidity | High inherent rigidity due to the angled strands, excellent for load-bearing. | Less rigid than standard, but offers better surface contact and aesthetic. |

| Applications | Walkways, platforms, security cages, machine guards, grates where grip and strength are primary. | Ceiling tiles, wall cladding, infill panels, decorative screens, filters, where aesthetics and smooth handling are important. |

| Cost | Generally lower due to fewer processing steps. | Slightly higher due to the additional flattening process. |

Industry Trends and Market Dynamics

The market for expanded metal mesh is dynamic, driven by increasing demands across key industrial and architectural sectors. Current trends indicate a significant growth in specialized applications, particularly those prioritizing material efficiency, sustainability, and aesthetic integration.

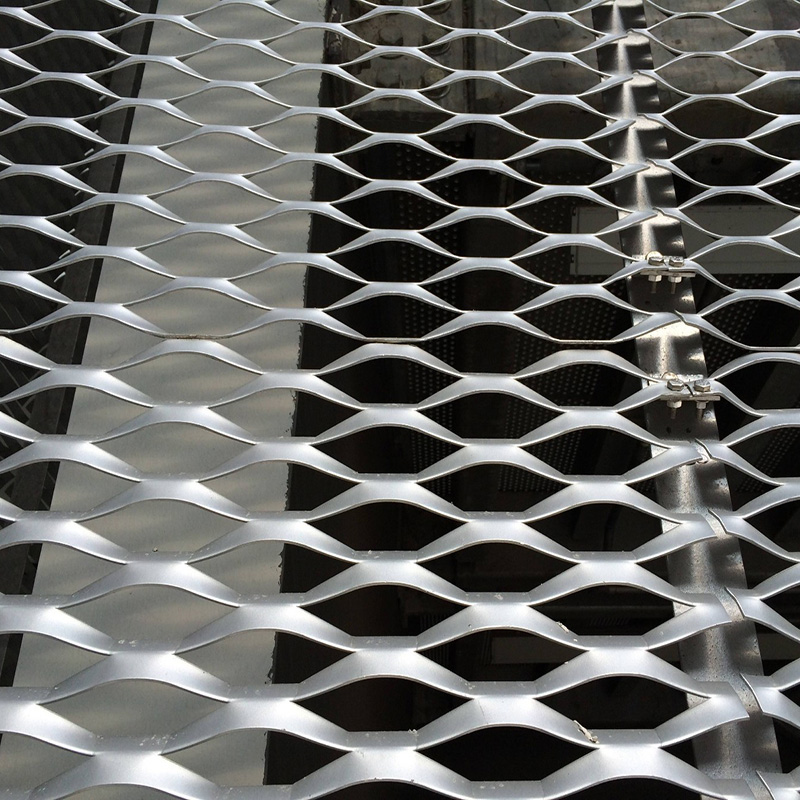

- Sustainable Construction: Growing emphasis on 'green' building materials favors expanded metal mesh due to its minimal waste production during manufacturing and high recyclability. Architects are increasingly specifying custom flat expanded metal mesh for energy-efficient facades and sun shading.

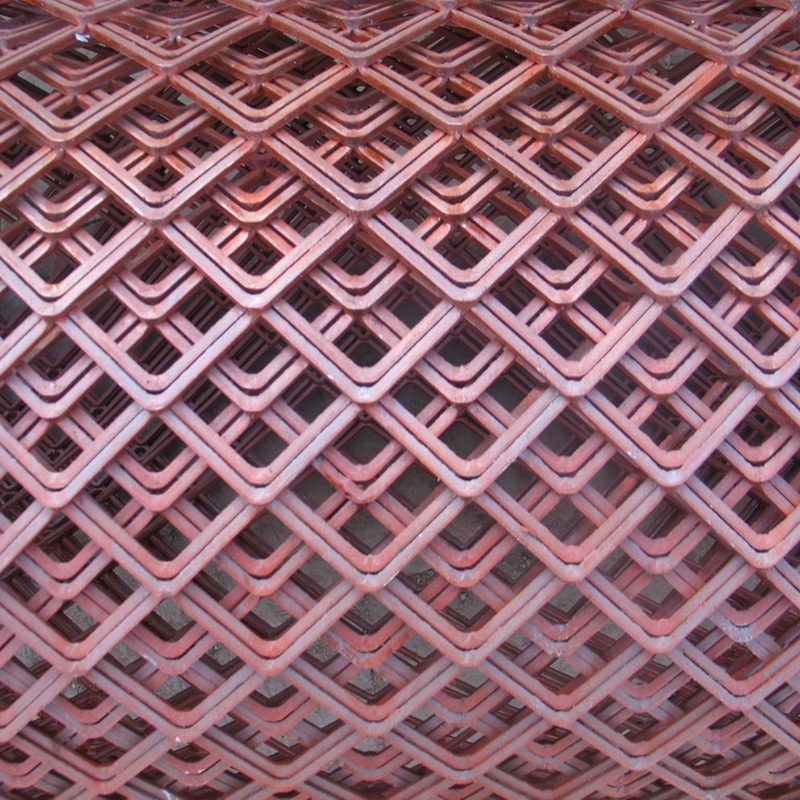

- Enhanced Security: The rise in demand for robust security solutions for critical infrastructure, data centers, and industrial facilities continues to drive the market for heavy-duty expanded metal mesh as an effective barrier against intrusion.

- Architectural Versatility: Advances in powder coating and fabrication techniques allow for broader creative applications, making powder coated expanded metal mesh a popular choice for decorative panels, balustrades, and interior design elements.

- Industrial Filtration and Separation: The need for efficient filtration in petrochemical, water treatment, and food processing industries is pushing innovation in specialized alloys and finer mesh patterns for precision screening and fluid management.

- Customization and Just-in-Time Delivery: Clients increasingly require custom expanded metal mesh and rapid fulfillment. This necessitates manufacturers to invest in advanced CNC-controlled expanding machinery and optimized supply chain logistics for wholesale expanded metal mesh orders.

Figure 3: Modern architectural application of expanded metal mesh.

Application Scenarios and Case Studies

The inherent versatility of expanded metal mesh makes it suitable for a vast array of demanding industrial and commercial applications. Its open structure, combined with exceptional strength, provides solutions for many engineering challenges.

Target Industries:

- Petrochemical: Used in catalytic converters, filtration systems, and safety grating on offshore platforms, where corrosion resistance and structural integrity are critical.

- Metallurgy & Mining: Screening, conveyor guards, separation equipment, and walkways in harsh, abrasive environments.

- Water Supply & Drainage: Pre-filtration, storm drains, and waste screening, utilizing its open area for efficient flow and debris capture.

- HVAC Systems: Air filters, grilles, and ventilation covers due to its optimal airflow properties.

- Architectural & Construction: Facades, sunscreens, balustrades, ceiling panels, and security fencing, often as custom flat expanded metal mesh.

- Automotive: Grilles, filtration elements, and acoustic dampening panels.

Application Case Studies:

A major energy company required durable, slip-resistant walkways for an offshore oil platform in the North Sea. Traditional solid gratings posed issues with heavy weight and maintenance in highly corrosive conditions. We provided heavy-gauge galvanized expanded metal mesh sheets. The open design allowed for excellent drainage of seawater and reduced wind resistance, enhancing safety. The hot-dip galvanization offered superior corrosion resistance, ensuring a long service life of over 25 years without significant degradation, leading to reduced maintenance costs and improved worker safety.

For a critical infrastructure project, advanced security fencing was needed to deter unauthorized access. Standard chain-link fences were deemed insufficient. We supplied robust steel expanded metal mesh panels with small SWD, making them difficult to cut or climb without specialized tools. The inherent rigidity and sharp edges of the bonds provided an effective deterrent. The panels were powder coated for enhanced durability and visual integration with the surrounding environment, successfully meeting the project's stringent security requirements.

An architectural firm sought an aesthetic yet functional solution for a new office building's facade in a sunny climate. They opted for large aluminum flat expanded metal mesh panels, finished with a specialized powder coating. These panels served as effective sunshades, reducing solar heat gain and lowering the building's cooling load by an estimated 15-20%. The open mesh design maintained natural light and outward visibility while creating a distinctive modern aesthetic, demonstrating significant energy saving advantages.

Figure 4: Expanded metal mesh in industrial safety application.

Technical Advantages of Expanded Metal Mesh

The unique characteristics of expanded metal mesh offer distinct advantages over other material forms, making it a preferred choice for demanding B2B applications.

- Superior Strength-to-Weight Ratio: By expanding rather than weaving or perforating, the metal retains its inherent strength while significantly reducing weight. This is crucial for applications where load-bearing capacity and material efficiency are critical, such as industrial platforms and lightweight structures.

- Enhanced Corrosion Resistance: When manufactured from stainless steel or subjected to processes like hot-dip galvanization or powder coating, the expanded metal mesh exhibits exceptional resistance to environmental degradation, extending its service life in harsh chemical, marine, or outdoor settings.

- Excellent Ventilation and Light Transmission: The open diamond pattern ensures optimal passage of air, light, heat, and fluids. This is invaluable for HVAC systems, architectural sunshades (promoting energy saving by reducing cooling loads), and safety guarding where visibility is required.

- Cost-Effectiveness & Material Efficiency: The expansion process creates no material waste, leading to a highly efficient use of raw materials. This results in significant cost savings, especially for wholesale expanded metal mesh orders.

- Slip Resistance: The raised strands of standard expanded metal mesh provide a naturally textured, anti-slip surface, making it ideal for walkways, stair treads, and ramps in industrial environments, enhancing safety.

- Security & Deterrence: The rigid, unitary construction without welds or joins makes it extremely difficult to cut or breach, providing high levels of security for fencing, cages, and protective barriers.

- Versatile Aesthetic Options: Available in various materials, patterns, and finishes (e.g., powder coated expanded metal mesh), it offers designers immense flexibility for architectural and decorative applications, blending functionality with modern aesthetics.

Vendor Comparison and Selection Criteria

Choosing the right expanded metal mesh supplier is crucial for project success. B2B decision-makers should evaluate vendors based on several key criteria beyond just price, focusing on long-term value, reliability, and capability.

- Manufacturing Expertise and Capacity: Look for experienced expanded metal mesh manufacturers with a proven track record, state-of-the-art machinery, and the capacity to handle both small custom orders and large wholesale expanded metal mesh requirements efficiently. Inquire about their process controls and quality assurance protocols.

- Material Quality and Certifications: A reputable expanded metal mesh supplier will use high-grade raw materials and provide material test certificates. Verify certifications like ISO 9001:2015, which attest to robust quality management systems.

- Customization Capabilities: The ability to produce custom expanded metal mesh, including specific mesh patterns (LWD, SWD), strand widths, thicknesses, materials, and finishes (e.g., custom flat expanded metal mesh, powder coated expanded metal mesh), is vital for unique project specifications.

- Technical Support and Engineering Assistance: A strong vendor offers expert advice on material selection, design optimization, and application challenges. This includes providing detailed technical drawings and performance data.

- Logistics and Global Reach: For international projects, assess the expanded metal mesh exporters' capabilities in efficient shipping, customs handling, and timely delivery. Reliability in fulfilling wholesale expanded metal mesh sheet orders globally is a key differentiator.

- Reputation and Client Testimonials: Investigate the supplier’s market reputation, years in service, and request references or case studies from similar projects. Long-standing relationships with leading industrial clients indicate trustworthiness.

Figure 5: Custom fabrication for expanded metal mesh solutions.

Customized Solutions

Understanding that no two projects are identical, we specialize in providing bespoke expanded metal mesh solutions tailored to precise client requirements. Our advanced manufacturing capabilities allow for extensive customization, ensuring that the final product perfectly aligns with your engineering and aesthetic specifications.

- Material Selection: From various grades of carbon steel, stainless steel (304, 316, 316L), aluminum, and exotic alloys, selected for specific environmental and performance needs.

- Mesh Pattern and Size: Custom LWD and SWD combinations to achieve desired open area, filtration efficiency, and structural rigidity. We offer a wide range from fine mesh for filters to heavy-duty mesh for industrial platforms.

- Strand Width and Thickness: Adjustable parameters to control overall strength, weight, and aesthetic.

- Form and Finish: Production of both standard (raised) and custom flat expanded metal mesh to suit functional or decorative applications. A wide array of finishes, including hot-dip galvanizing, electro-galvanizing, various powder coated expanded metal mesh colors, anodizing, and custom paint applications.

- Fabrication and Assembly: Capabilities for cutting, bending, forming, and welding to create complex components or pre-fabricated assemblies, reducing on-site labor for our clients. Whether you need a custom expanded metal mesh sheet or intricate assemblies, our factory is equipped to deliver.

Our team of engineers collaborates closely with clients from conceptualization to delivery, ensuring that every custom expanded metal mesh solution meets the highest standards of quality and performance.

Logistics, Warranty, and Support

We understand that reliable logistics, clear warranty terms, and robust after-sales support are integral to our B2B partnerships.

Lead Time & Fulfillment:

Our streamlined production processes and efficient supply chain management ensure competitive lead times for both standard and custom expanded metal mesh orders.

- Standard Products: Typically 7-14 business days from order confirmation to dispatch for readily available specifications of expanded metal mesh sheet.

- Custom Orders: Lead times for custom expanded metal mesh vary based on complexity, material availability, and required finishing, generally ranging from 3-6 weeks. Detailed timelines are provided with each custom quotation.

- Shipping: We offer various shipping options, including sea freight, air freight, and expedited courier services, ensuring global reach as leading expanded metal mesh exporters. Comprehensive documentation and customs support are provided for international shipments.

Warranty Commitments:

All our expanded metal mesh products are backed by a comprehensive warranty against manufacturing defects and material failure under normal operating conditions.

- Structural Integrity: 5-10 year warranty on the structural integrity of the mesh, depending on material and application.

- Finishes: 2-5 year warranty on protective coatings (e.g., galvanization, powder coating) against chipping, peeling, or significant fading, provided proper installation and maintenance guidelines are followed.

- Specific warranty details are provided with each product order and can be reviewed in our standard terms and conditions.

Customer Support:

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and any post-purchase concerns.

- Technical Assistance: Access to our engineering team for application-specific advice and troubleshooting.

- Order Management: Real-time updates on production and shipping status.

- After-Sales Service: Prompt handling of any warranty claims or quality concerns.

- Contact us via email at sales@examplemesh.com or call +1-800-123-4567 for immediate assistance.

Frequently Asked Questions (FAQ)

A: Standard (or raised) expanded metal mesh has strands and bonds that are set at a uniform angle to the plane of the sheet, giving it a three-dimensional, ribbed surface. Flat expanded metal mesh is produced by cold-rolling standard mesh, which flattens the strands and bonds to create a smooth, even surface. This makes flat mesh ideal for architectural and decorative applications where a smooth finish is desired, while standard mesh offers better grip and higher rigidity for heavy-duty uses like walkways.

A: The open area percentage of a expanded metal mesh directly correlates with its ability to permit the passage of air, light, heat, and fluids. A higher open area means better flow rates for filtration or increased light and air penetration for facades. Conversely, a lower open area offers greater structural strength and privacy, often chosen for security applications. Selecting the appropriate open area is critical for optimizing functionality.

A: Yes, with the correct material and finish. For highly corrosive environments like marine or chemical processing plants, stainless steel (e.g., 316L) expanded metal mesh is highly recommended. Additionally, hot-dip galvanization or specialized powder coated expanded metal mesh treatments can provide significant protection to carbon steel mesh, extending its service life and maintaining performance.

A: Custom expanded metal mesh is utilized when standard specifications do not meet unique project requirements. This includes bespoke architectural designs, specialized filtration screens with precise pore sizes, custom machine guards for unusual equipment, and tailor-made security barriers. Our ability to provide custom expanded metal mesh sheet solutions allows architects and engineers to overcome design limitations and achieve optimal performance for specific functional or aesthetic goals.

Conclusion

Expanded metal mesh represents a pinnacle of material engineering, offering an unparalleled blend of strength, versatility, and cost-effectiveness. Its unique manufacturing process yields a product with superior structural integrity, excellent open area for ventilation and filtration, and inherent safety features. From the rigorous demands of the petrochemical and metallurgy industries to the aesthetic finesse required in modern architecture, expanded metal mesh continues to provide robust and innovative solutions. As leading expanded metal mesh manufacturers and exporters, we are committed to delivering high-quality, custom expanded metal mesh solutions that meet the evolving needs of global industries, ensuring both performance and value.

References

- ASTM International. (2018). ASTM F1267, Standard Specification for Metal, Expanded, Steel, for Fencing and Security Mesh.

- ISO. (2015). ISO 9001:2015, Quality management systems — Requirements.

- National Association of Architectural Metal Manufacturers (NAAMM). (2009). Metal Bar Grating Manual, MBG 531-09.

- The Expanded Metal Manufacturers Association (EMMA). (2020). Technical Manual: Expanded Metal Guide.

- Smith, J. & Jones, R. (2022). "Advancements in Cold Forming Techniques for Mesh Materials in Construction." Journal of Material Science and Engineering, 45(2), 123-135.

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025

-

Barbed Wire Fence: Durable Security Solutions for Global Agriculture and Industry

NewsNov.19,2025

-

Barbed Wire: Durable & Affordable Security Solutions for Global Applications

NewsNov.18,2025

-

Durable and Cost-Effective Fence Wire Mesh for Farm Sheep – Global Insights & Innovations

NewsNov.18,2025

-

Durable and Cost-Effective Farm Fencing Wire Galvanized | Global Use & Benefits

NewsNov.15,2025

-

Essential Guide to Wire for Fencing: Applications & Innovations

NewsNov.14,2025