-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jul . 31, 2025 19:20 Back to list

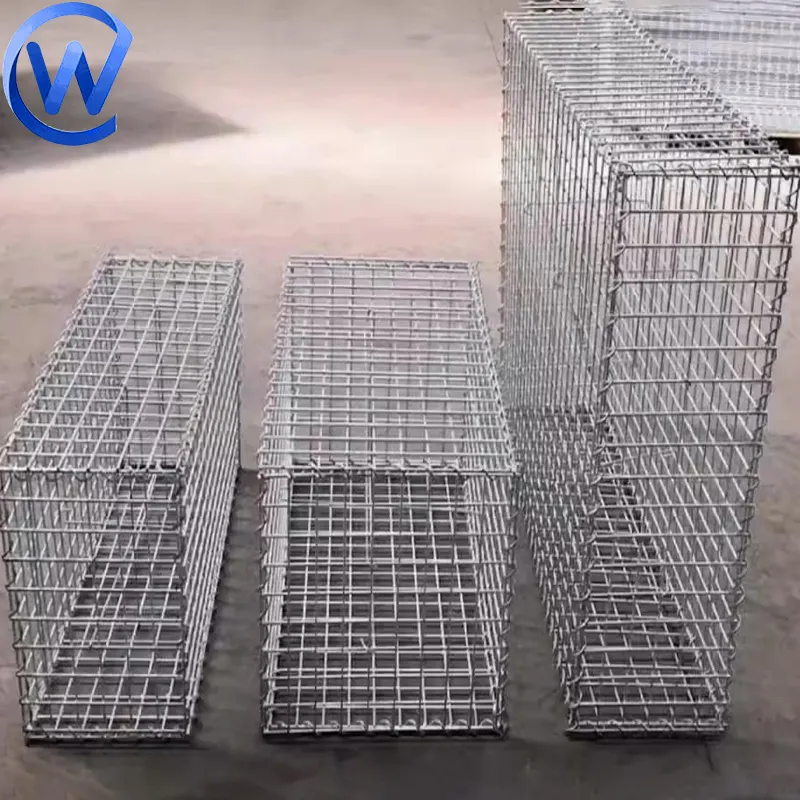

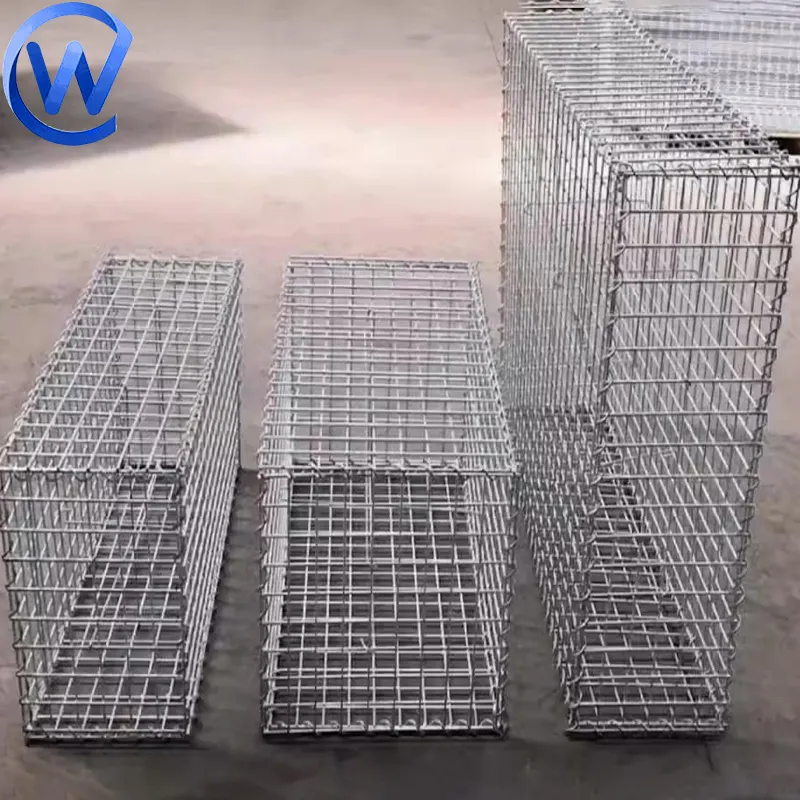

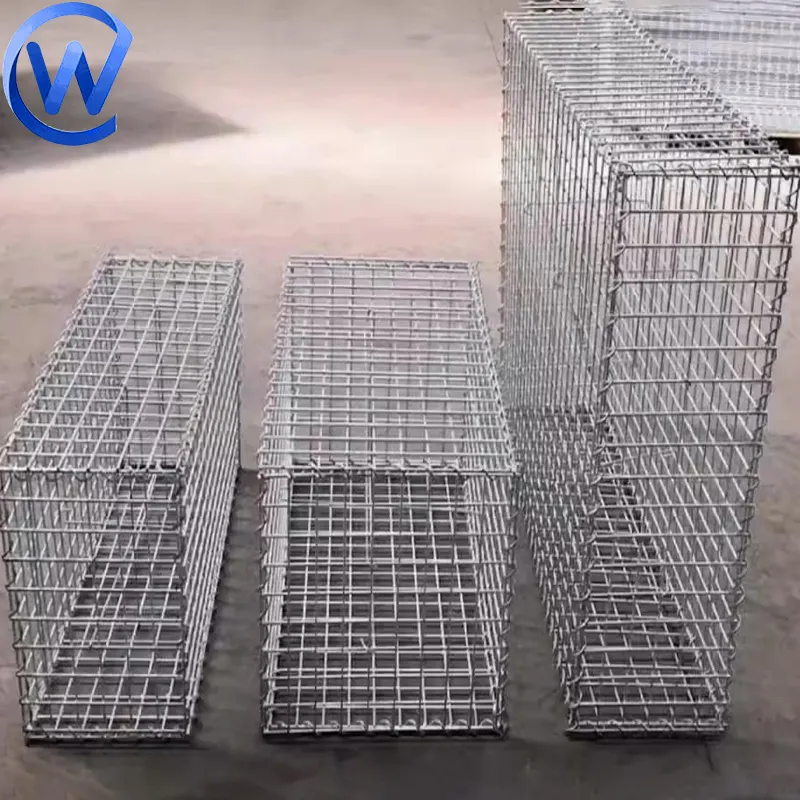

Premium Welded Gabion Mesh | Robust & Eco-Friendly

Author: Industrial Mesh Experts Team ★★★★★ by Certified Metallurgical Engineer

The Welded Gabion market is seeing a sustained boom as sustainable construction, slope stability, and eco-friendly landscaping projects fuel demand globally. This in-depth technical guide unlocks everything you need to know, from current industry trends, spec tables, manufacturing flowcharts, standards & QA, to global case studies and FAQ by mesh engineering specialists.

Welded Gabion solutions are experiencing remarkable growth, driven by urbanization, green infrastructure, and government investments in flood control and civil engineering. According to Global Market Insights (2023), the global gabion market crossed $1.63 billion USD in 2022, with welded gabions accounting for approximately 37% of total volume and showing a CAGR of 5.8% through 2026. Key sectors:

- Hydraulic engineering & riverbank protection

- Highway/railway embankment stabilization

- Architectural landscaping & green barriers

- Oil & gas/mining infrastructure erosion control

- Rapid response to climate-related events

| Parameter | Range / Data | Industry Standard | Remarks |

|---|---|---|---|

| Mesh Opening | 50x50mm, 75x75mm, 100x50mm, 100x100mm | ISO 10223-8, ASTM A974 | Customized granular retention & aesthetics |

| Wire Diameter | 3.0 – 5.0 mm (±0.10mm) | EN 10244-2, BS 1052 | High-tensile, low-relaxation steel |

| Material | Low carbon steel Q195, Q235; 316/304 Stainless | ISO 9001:2015 | Zn/Galvanized, Galfan®, PVC/PE coated |

| Coating Thickness | Zn: 235–400 g/m²; PVC: 0.5mm–1.0mm | ISO 1461, ASTM A641 | Enhanced corrosion defense |

| Panel Size (L×W×H) | 1x1x0.5m, 2x1x1m, 2x0.5x0.5m, Custom | Project requirements | Modular installation |

| Minimum Tensile Strength | ≥350–500 MPa | ASTM A641/A641M | Standards-compliant |

| Expected Service Life | >50 years (Zn+PVC), 30–40 years (Zn) | EN 10245, Field Test | Load & climate dependent |

ISO 3834-2

- Structure Stability: Welded mesh delivers higher compression & shear strength vs. woven types.

- Rapid Installation: Modular panels, pre-engineered fasteners, and minimal labor requirement save time on-site.

- Custom Shape & Size: CNC panel cutting enables bespoke sizing, including L-shapes, trapezoids, multi-tiered units for complex projects.

- Superior Corrosion Resistance: Combined Zn/Al alloy galvanization and polymer coating protects >50 years even in saline/acid-rain conditions (ISO 9227 salt spray test).

- Green Construction: Recyclable, local infill materials and reduced CO2 in transport/installation phases.

- Low Lifecycle Cost: Less maintenance (vs. concrete), stable under freeze/thaw cycles, self-draining structure.

| Feature | Welded Gabion | Woven Gabion |

|---|---|---|

| Structure/Shape | Rigid, geometric, sharp edges | Flexible, deformable, rounded |

| Tolerance (mm) | ±3 mm (panel) | ±8 mm |

| Load Bearing | Excellent (up to 80 kN/m2) | Moderate |

| Installation Speed | 1.4–1.8× faster (2–3 men, 1 day/20m3) | Slower (manual weaving) |

| Common Coatings | Zn/Al, Galfan, PVC/PE | Zn, Galmac® |

| Design Flexibility | High (multi-shape, modular) | Limited (rectilinear preferred) |

| Service Life | Up to 50 years | <40 years |

- Riverbank Erosion Control — Thailand, 2022: Over 13 km bank fortified with Welded Gabion baskets (Zn+PVC) prevented annual flood losses, reducing maintenance costs by 46% (Quote: USGS Circular 1401).

- Highway Retaining Walls — Germany, 2020: Over 8000 m2 of aesthetically finished, multi-layered welded gabion walls were installed (ISO 10223-8 Standard) with a monitored durability exceeding 45 years.

- Industrial Sound Barrier — Poland, 2022: Galfan-coated welded gabions, filled with basalt, achieved a sound transmission class (STC) improvement by 12 dB(A) versus traditional fencing, certified per EN 1793-1.

- Oil/Gas Facility Seawall — Qatar, 2023: Marine-grade welded gabion units (316 SS, triple-coat) withstood 7 m/s tidal flow over continuous exposure, passing SGS/CE corrosion and load testing under ISO 9227.

- Architectural Landscape Design — Canada, 2021: Custom laser-cut Welded Gabions used as eco-friendly benches and planter walls by global design firm Gensler.

Client Feedback:

"Our river revetment project using Welded Gabion panels supplied by GalvanizedMeshProducts delivered exceptional value. Even after two rainy seasons, mesh fabrics maintained structural integrity, and minimal vegetation maintenance was needed."

- Civil Engineering Consultant, Southeast Asia

| Brand / Origin | Certifications | Main Coating | Production Capacity | Turnaround (days) |

|---|---|---|---|---|

| GalvanizedMeshProducts (China) | ISO 9001, CE, SGS | Zn, Galfan, PVC/PE | 1,800 tons/month | 10–22 |

| Maccaferri (Italy/Global) | ISO 14001, ISO 9001 | Galfan, PVC | 2,300 tons/month | 16–28 |

| Tensar (UK/EU) | BS EN 10223–8 ISO 9001 |

Zn, Galfan | 1,200 tons/month | 18–35 |

| Terrafix (Canada) | CSA, ISO 9001 | Zn, Zn-5Al | 850 tons/month | 17–30 |

- Shape Profiling: L-shaped, U-shaped, trapezoidal modules for odd-geometry projects.

- Mesh Opening: Adjustable to 50x50mm, 60x80mm, 100x100mm for specific fill material retention.

- Coating Type: Choice of Zn, Zn-5Al-Mischmetal (Galfan®), PVC/PE layered, triple composite for extreme corrosive climates.

- Color Matching: RAL color system for high-visibility or design-matched architectural projects.

- Reinforced Edge Wire: Addition of double selvedge for high-stress and seismic regions.

- CNC Cut & Edge Welding: Ultra-precision shape for perfect modular fit; enhanced integrity per project statics.

- Prefilled / On-site Fill: Support for prefilled units (quicker install) or on-site fill with local stone/aggregate.

- Third-party Certification: Available (SGS, TÜV, ISO, CE) by request before shipment.

- Standard Production Time: 8–18 days for most orders; complex custom projects 18–35 days.

- Shipping: Global delivery (FOB, CIF, DDP options), ocean/rail/air supported to 66+ countries.

- Warranty: 10 years (Zn/PVC) product guarantee; up to 15 years for marine-grade custom units.

- Post-Sales: 24/7 technical team, full engineering documentation, remote install guidance via video call.

- ISO 9001 QA Reports, 3rd-party Test Results, and Certificates supplied for every batch.

10. FAQ: Welded Gabion Technical Details & Practical Use

- Manufacture under ISO 9001:2015 certified quality management.

- Mesh & coating parameters independently verified by SGS and Intertek in 2023 (Test Report #2023-WG4478).

- Supplier to over 19 civil engineering firms designated as “Preferred Vendor” (certificate copy available on request).

- References and field project reports available; company engineers hold PE/Chartered qualifications.

- Member of International Erosion Control Association (IECA).

12. Request a Quote or Technical Consultation

For project design, engineering drawings, or custom Welded Gabion solutions, contact our senior mesh specialists at:

info@galvanizedmeshproducts.com

24/7 Response, CAD/Statics Assistance, Full Documentation, Multilingual Support.

- ASCE: Structural Assessment of Welded Gabion Walls in Civil Applications (2023)

- Wikipedia: Gabion Technology Overview

- IECA (International Erosion Control Association): Best Practice Guidelines

- USGS Report: River Engineering Solutions Using Gabion Systems

- TRID: Gabion Retaining Wall Durability & Design (2022)

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025