-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 10, 2024 16:07 Back to list

pvc coated wire mesh roll factory

PVC Coated Wire Mesh Roll Factory A Comprehensive Overview

In today's industrial landscape, the demand for durable and versatile materials is on the rise. One such material that has gained significant popularity is PVC coated wire mesh. This article explores the intricacies of a PVC coated wire mesh roll factory, shedding light on its production processes, applications, and benefits.

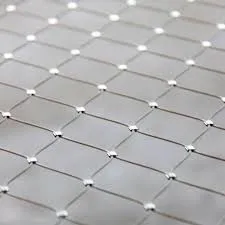

Understanding PVC Coated Wire Mesh

PVC coated wire mesh consists of a metal wire mesh that is coated with polyvinyl chloride (PVC) to enhance its resistance to corrosion, UV rays, and chemical exposure. This combination results in a robust and flexible material that is suitable for various environments, from agricultural to industrial applications.

The Manufacturing Process

The production of PVC coated wire mesh rolls involves several key steps

1. Wire Selection High-quality steel wires, usually galvanized to prevent rusting, are selected for manufacturing. The choice of wire gauge depends on the intended application.

2. Weaving The selected wires are woven together in a mesh pattern. This step requires precision to ensure that the mesh has uniform openings and strength.

3. Coating The woven wire mesh is then coated with a layer of PVC. This is done through various methods, including dip coating and electrostatic spraying. The thickness of the PVC coating can vary based on customer requirements and specific usage.

4. Curing After coating, the wire mesh is cured in an oven to ensure the PVC adheres firmly to the wire, providing long-lasting protection against environmental factors.

pvc coated wire mesh roll factory

5. Cutting and Rolling Once cured, the mesh is cut into desired sizes and rolled into convenient lengths for packaging and distribution.

6. Quality Control A stringent quality control process is conducted to test the mesh's durability, tensile strength, and resistance to corrosion.

Applications of PVC Coated Wire Mesh

Due to its versatile nature, PVC coated wire mesh has a wide range of applications, including

- Fencing Commonly used for residential and commercial fences, providing security without compromising visibility. - Agricultural Use Employed in livestock enclosures, crop protection, and as trellising for climbing plants. - Construction Used in building, roadwork, and as reinforcement in concrete. - Industrial Applications Ideal for shelving, storage cages, and partitions in warehouses.

Benefits of PVC Coated Wire Mesh

1. Durability The PVC coating significantly enhances the material’s lifespan by preventing rust and degradation. 2. Low Maintenance Unlike untreated wire mesh, PVC coated options require minimal upkeep and can be easily cleaned. 3. Aesthetic Appeal Available in various colors, PVC coated wire mesh can blend seamlessly into different environments and enhance visual appeal. 4. Safety The smooth and flexible nature of PVC reduces the risk of injury from sharp edges, making it a safer choice for various applications.

Conclusion

The PVC coated wire mesh roll factory plays a crucial role in producing a material that meets the diverse needs of modern industries. With its combination of durability, versatility, and aesthetic appeal, PVC coated wire mesh continues to be a preferred choice for a wide range of applications. As innovative production techniques evolve, we can anticipate even more advancements in this vital material, ensuring it remains essential in various sectors for years to come.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025