-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 09, 2024 08:37 Back to list

PVC Coated Welded Wire Mesh Panel Suppliers for Various Applications

Understanding PVC Welded Wire Mesh Panels Manufacturers’ Insights

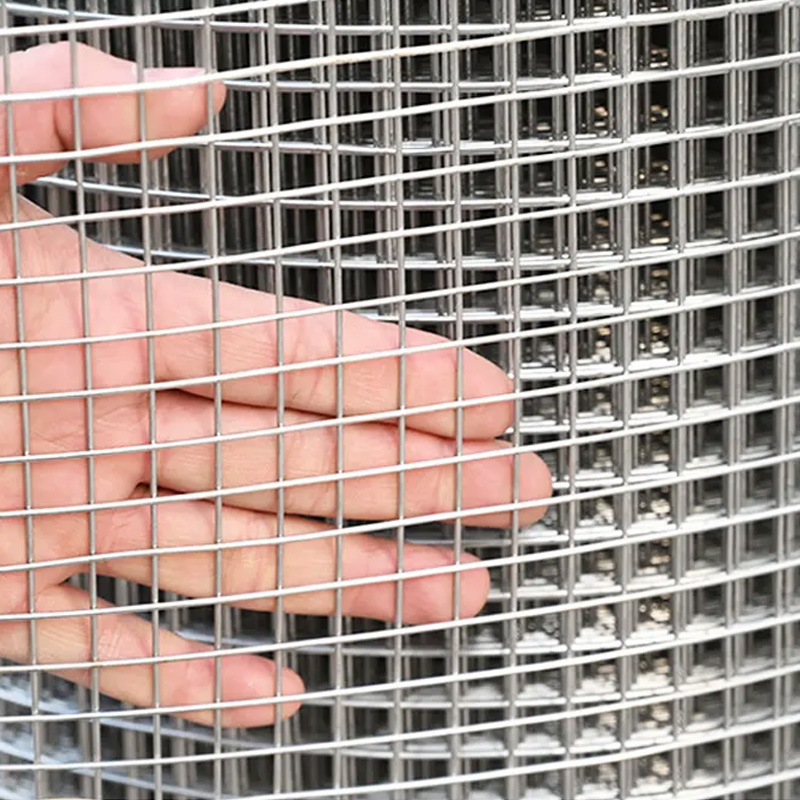

PVC welded wire mesh panels have gained significant popularity in various applications due to their durability, versatility, and aesthetic appeal. These panels are made by welding together steel wires and then coating them with polyvinyl chloride (PVC) to enhance their corrosion resistance and longevity. This article will explore the benefits, manufacturing process, and key considerations when choosing PVC welded wire mesh panels.

What Are PVC Welded Wire Mesh Panels?

PVC welded wire mesh panels are comprised of high-quality steel wires that are welded at the junctions to create a robust grid structure. After the welding process, the panels are coated with PVC, which serves as a protective layer against environmental factors. This coating not only increases the lifespan of the mesh but also adds color and a smooth finish, making it suitable for various aesthetic needs.

Benefits of PVC Welded Wire Mesh Panels

1. Durability One of the most significant advantages of PVC welded wire mesh panels is their enhanced durability. The steel structure provides high tensile strength, while the PVC coating protects against rust and degradation from weather elements.

2. Corrosion Resistance Unlike untreated steel, which can easily corrode over time, PVC-coated panels resist rust and corrosion, making them ideal for outdoor applications, such as fencing, garden borders, and animal enclosures.

3. Low Maintenance The non-porous surface of PVC makes it easy to clean and maintain. Unlike traditional wooden fences or other materials that may require routine painting or sealing, PVC mesh only needs occasional cleaning to look its best.

4. Versatility These panels can be used for various applications, including residential, commercial, agricultural, and industrial projects. From protective fences to decorative elements in landscaping, the versatility of PVC welded wire mesh panels makes them an excellent choice for many architecturally-driven designs.

5. Aesthetic Appeal Manufacturers offer PVC welded wire mesh panels in various colors and finishes, allowing for seamless integration into different environments while enhancing visual appeal. This aspect is particularly valuable in applications where aesthetics are as important as functionality.

Manufacturing Process

The manufacturing of PVC welded wire mesh panels involves several critical steps

1. Wire Selection High-quality steel wire is chosen based on thickness and strength requirements. Typically, low carbon steel is used for its strength and workability.

pvc welded wire mesh panel manufacturers

2. Welding The wires are arranged in a grid pattern and welded together at their intersections using an electric resistance welding technique. This produces a tight and robust connection between the wires.

3. Surface Preparation After welding, the panels undergo a surface treatment to remove any impurities or oxides that may affect the coating's adhesion.

4. PVC Coating The final step involves applying a layer of PVC through either dipping or electrostatic spraying. This process ensures that every part of the panel is coated, providing comprehensive protection.

5. Quality Control Before the panels are packaged and dispatched, they undergo rigorous quality checks to ensure they meet industry standards and customer specifications.

Choosing the Right Manufacturer

When selecting a manufacturer for PVC welded wire mesh panels, consider the following factors

1. Reputation Research the manufacturer’s reputation in the industry. Look for customer reviews, case studies, and testimonials that can vouch for their reliability and quality.

2. Product Range A good manufacturer should offer a variety of panel sizes, wire thicknesses, and colors to meet different project needs.

3. Customization Options Depending on your specific requirements, you may need customized solutions. Ensure the manufacturer can provide these options.

4. Quality Assurance Ask about the quality control measures they implement during the manufacturing process. Reliable manufacturers should adhere to industry standards.

5. Sustainability Practices In today’s market, many consumers consider a manufacturer’s environmental practices. Inquire whether the manufacturer employs sustainable practices in sourcing materials and production.

Conclusion

PVC welded wire mesh panels are an excellent solution for a wide range of applications due to their durability, aesthetic appeal, and low-maintenance properties. By understanding the manufacturing process and considering the key factors when selecting a manufacturer, you can ensure that you get the best product for your specific needs. The growing demand for these panels highlights their undeniable value in modern construction and landscaping practices.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025