-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Aug . 22, 2024 04:18 Back to list

Quality Galvanized Wire Mesh Production for Diverse Applications and Industries

The Role of Galvanised Wire Mesh Manufacturers in Modern Industries

Galvanised wire mesh has become a crucial material across various industries due to its strength, durability, and resistance to corrosion. As the demand for reliable fencing, safety barriers, and industrial applications continues to grow, galvanised wire mesh manufacturers play a pivotal role in providing high-quality products that meet diverse needs. This article explores the significance of these manufacturers and the various applications of galvanised wire mesh.

Understanding Galvanised Wire Mesh

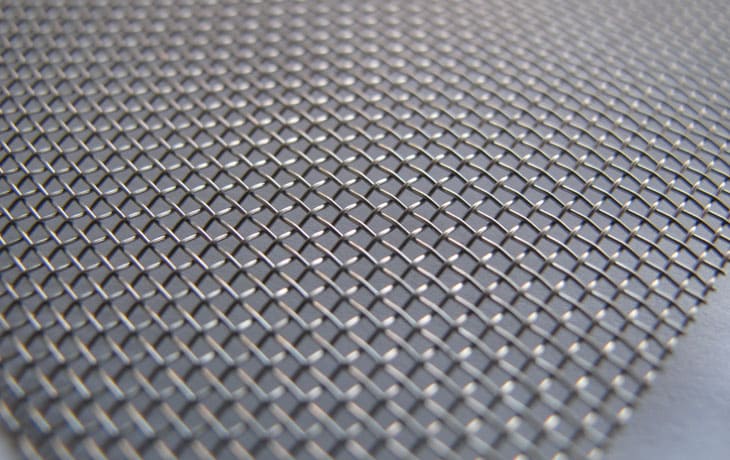

Galvanised wire mesh is produced by coating steel wire with a layer of zinc to protect against corrosion. This process, known as galvanisation, enhances the wire's lifespan, making it suitable for both indoor and outdoor applications. The mesh can be made in various sizes and thicknesses, allowing for customization based on specific requirements. The manufacturing process itself involves weaving or welding the wires together to create a robust mesh structure.

Importance of Quality in Manufacturing

The quality of galvanised wire mesh is paramount, as it influences its performance in various applications. Reliable manufacturers utilize high-grade raw materials and adhere to strict quality control measures to ensure their products meet international standards. This commitment to quality not only provides customers with durable and reliable products but also builds a strong brand reputation in a competitive market.

Furthermore, manufacturers often invest in advanced technology and machinery to enhance production efficiency and precision. This focus on innovation allows them to produce mesh that is not only strong but also cost-effective, providing better value to customers.

galvanised wire mesh manufacturer

Applications of Galvanised Wire Mesh

Galvanised wire mesh finds applications in a wide range of industries. In construction, it is frequently used for reinforcement in concrete, as it provides strength and stability to structures. In agriculture, farmers use galvanised wire mesh for fencing livestock and protecting crops from pests. The versatility of this material also extends to the manufacturing of products such as shelves, cages, and containers, which require a durable and sturdy construction.

Moreover, in the field of landscaping, galvanised wire mesh serves as an excellent choice for erosion control and soil stabilization. Its strength and resistance to weathering make it ideal for use in gabion baskets, which are used to hold stones and create structures like retaining walls and riverbank protections.

Conclusion

As industries continue to evolve, the demand for high-quality materials like galvanised wire mesh will only increase. Manufacturers in this field must prioritize quality, innovate their manufacturing processes, and understand the specific needs of their customers. By doing so, they can compete effectively in a global market while providing essential products that contribute to the safety and efficiency of various applications.

In essence, galvanised wire mesh manufacturers are not just suppliers; they are vital partners in ensuring durability and performance in numerous sectors. As we move forward, the role of these manufacturers will remain critical in supporting infrastructure, agriculture, and industrial operations, underscoring the importance of investing in quality materials and craftsmanship.

-

Premium Concertina Wire Manufacturer Global Exporters & Suppliers

NewsApr.29,2025

-

Galvanized Farm Fencing Wire Supplier Durable & Rust-Resistant

NewsApr.29,2025

-

Industrial Fence Manufacturer Durable & Custom Solutions for Export

NewsApr.29,2025

-

Stainless Steel Bird Spikes Durable & Effective Bird Deterrent

NewsApr.28,2025

-

Premium Stainless Steel Drain Grates Exporter & Manufacturer

NewsApr.28,2025

-

Durable Galvanized Razor Wire Manufacturer & Exporter High Security

NewsApr.28,2025