-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 09, 2024 02:08 Back to list

Reliable Quarry Screen Mesh Supplier for High-Quality Filtration Solutions

Quarry Screen Mesh Supplier Meeting Your Screening Needs

In the world of construction and mining, the importance of quality materials cannot be overstated. One critical component of any aggregate processing operation is the screen mesh, which plays a vital role in the separation and sorting of materials. For those looking for reliable quarry screen mesh suppliers, understanding the options available and the factors to consider is crucial in ensuring efficient operations and optimal productivity.

Understanding Screen Mesh in Quarry Operations

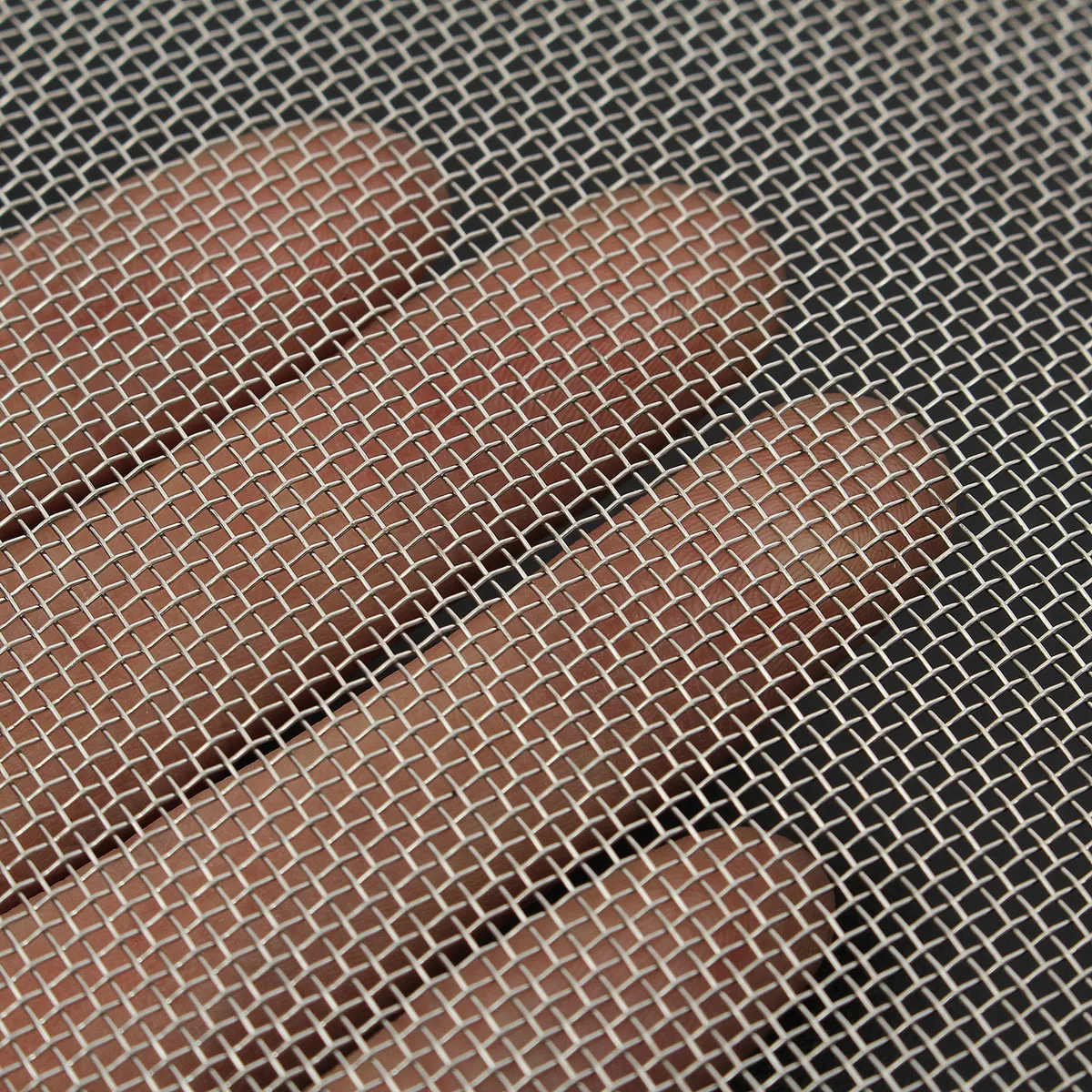

Screen mesh is a specialized form of screening equipment designed to separate materials of different sizes. In quarry operations, traditional screens use woven wire mesh to segregate gravel, stones, and other aggregates. The mesh size determines the particle size that can pass through it, making it essential to choose the right screen mesh for your specific needs.

Quarry screen mesh can be categorized into various types depending on the material used, the design of the screen, and the application. Common types include woven wire mesh, polyurethane screen panels, and modular screens, each serving distinct purposes and offering unique advantages.

Why Quality Matters

The efficiency of your quarry operation heavily relies on the quality of the screen mesh. Poor-quality mesh can lead to premature wear and tear, resulting in frequent replacements and project downtime. High-quality mesh helps to enhance the performance of the entire screening process, reduces operational costs, and ensures that the materials are sorted correctly, leading to better overall productivity.

A reputable quarry screen mesh supplier will offer products made from durable materials such as high carbon steel or stainless steel, ensuring that the screens can withstand the rigors of daily use. This durability translates into longevity, ultimately offering better returns on investment.

Factors to Consider When Choosing a Supplier

When searching for the right quarry screen mesh supplier, there are several factors to consider

quarry screen mesh supplier

1. Product Variety A reliable supplier should offer a wide range of mesh sizes and types to cater to different screening needs. Whether you require fine mesh for sand or larger openings for gravel, they should have options available.

2. Customization Every quarry operation is unique. Suppliers who can provide customized solutions tailored to your specific demands are invaluable. This could include custom-sized screens, different mesh patterns, or specialized materials.

3. Quality Assurance Inquire about the supplier's quality control processes. A reputable supplier should have certifications indicating that their products meet industry standards. This ensures that you are investing in reliable and tested materials.

4. Delivery and Logistics Timely delivery of materials is essential in preventing project delays. Choose a supplier with a solid logistical framework that can guarantee on-time delivery, minimizing interruptions to your operations.

5. Customer Support Effective communication and support can make a significant difference, especially when you need guidance on product selection or face issues with your screening equipment. A good supplier will offer excellent after-sales service to help you resolve any concerns.

The Role of Technology in Screen Mesh Production

With advancements in technology, the manufacturing process of screen mesh has evolved significantly. Modern suppliers leverage innovative techniques to produce more durable and efficient mesh screens. The use of computer-aided design (CAD) software and state-of-the-art machinery ensures precision in mesh fabrication, allowing for greater consistency and quality.

Additionally, advanced materials such as polymer composites are being utilized to create lightweight yet robust screens, enhancing performance while reducing overall operational loads.

Conclusion

Choosing the right quarry screen mesh supplier is a pivotal decision that can impact the efficiency, productivity, and profitability of your operations. By considering factors like product variety, customization, quality assurance, logistics, and customer support, you can discover a supplier that meets your specific needs. Investing in high-quality screen meshes from a trusted supplier not only helps in achieving better sorting of materials but also contributes to the longevity and performance of your quarry operation. As technology continues to evolve in this sector, staying informed about the latest products and innovations will ensure that your operations remain competitive and efficient.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025