-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 23, 2024 16:53 Back to list

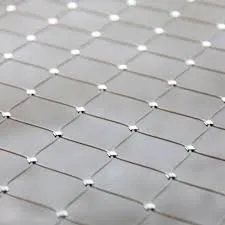

square mesh factory

The Importance of Square Mesh Factories in Modern Manufacturing

In today's fast-paced manufacturing domain, square mesh factories have carved out a distinctive niche, serving various industries with their efficient production capabilities. These specialized facilities are designed to produce square mesh materials, which have become indispensable in numerous applications, ranging from construction and agriculture to filtration and fencing. Understanding the operations and significance of square mesh factories can illuminate their vital role in modern manufacturing.

The Production Process

Square mesh is typically made from various materials, including steel, aluminum, and plastic, allowing for a diverse range of applications. The manufacturing process begins with raw materials that are cut into appropriate dimensions. The choice of material often depends on the intended use of the mesh; for example, stainless steel is preferred for applications requiring high durability and corrosion resistance, whereas plastic meshes might be utilized for lighter duties.

Once the raw materials are prepared, they undergo several processes, including weaving, welding, or extrusion, depending on the type of mesh being produced. Weaving involves interlacing wires or threads to form a grid structure, while welding is used to create a stronger bond between strands. Extrusion, on the other hand, involves forcing a plastic material through a mold to achieve the desired mesh shape.

After these processes, the meshes are subjected to rigorous quality checks to ensure that they meet industry standards. These quality controls are essential as they guarantee the strength, flexibility, and durability of the finished products. Square mesh factories employ advanced technology and stringent manufacturing practices to ensure their products can withstand the rigors of their intended applications.

Applications of Square Mesh

The versatility of square mesh products is a significant factor in their widespread usage. In the construction industry, square meshes are commonly used for reinforcement in concrete structures, as well as for safety barriers during construction projects. The ability to create strong, reliable components from square mesh makes it ideal for these applications.

square mesh factory

In agriculture, square mesh is utilized for various purposes such as crop protection, fencing, and fertilizer distribution. The mesh allows for adequate airflow while protecting crops from pests and harsh weather conditions. Additionally, farmers appreciate how easy it is to maneuver and install square mesh products in their fields.

In the realm of filtration, square meshes support water treatment facilities and various industrial processes. The precise openings in the mesh enable the filtering of different materials, ensuring that only the desired substances pass through. This capability not only enhances the efficiency of numerous operations but also contributes to environmental sustainability by preventing pollution.

Sustainability and Innovation

As industries move towards more sustainable practices, square mesh factories are adapting their procedures to reduce waste and energy consumption. Many manufacturers are investing in eco-friendly materials and technologies, emphasizing recycling and reusability in their product lines. These innovations represent a significant shift in manufacturing philosophy, focusing on the long-term sustainability of both the products and the environment.

In addition to sustainability, advancements in technology are also spurring innovation within square mesh production. Automation and computer-aided design (CAD) are increasingly being incorporated into factories, allowing for greater precision and efficiency. These technologies not only reduce labor costs but also enhance the overall quality of the final products, further solidifying the reputation of square mesh factories as leaders in the manufacturing sector.

Conclusion

In summary, square mesh factories play a crucial role in various industries by providing essential products that facilitate numerous applications. Their innovative manufacturing processes and commitment to quality ensure that they can meet the diverse needs of modern manufacturing. As we continue to advance into an era focused on sustainability and technological innovation, square mesh factories will remain at the forefront, contributing to efficient, reliable, and eco-friendly manufacturing solutions. The importance of square mesh cannot be overstated, as it continues to support and enhance a wide range of industrial operations around the globe.

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025