-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Oct . 31, 2024 04:21 Back to list

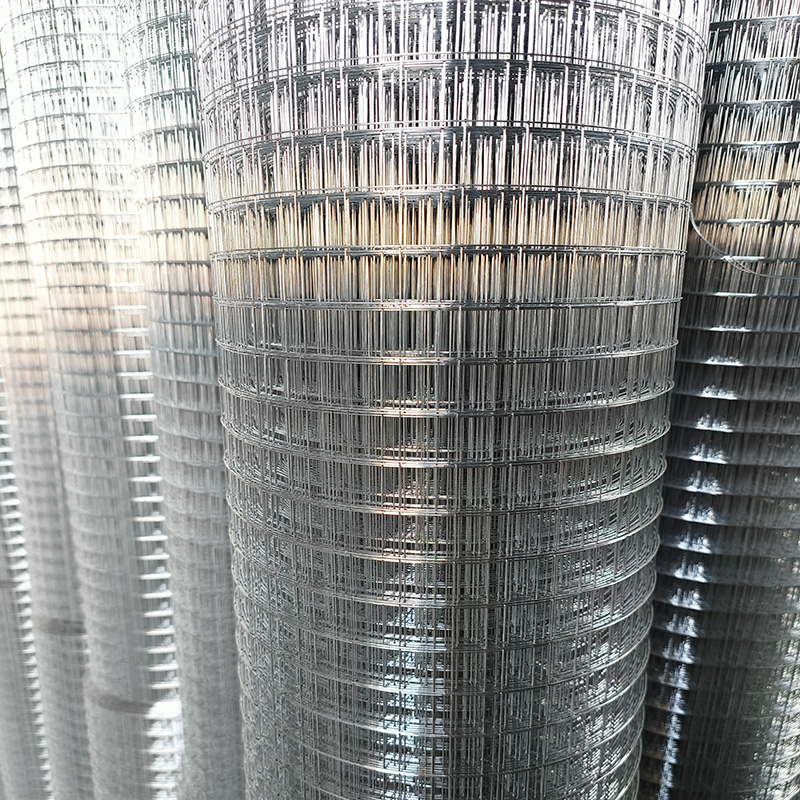

square mesh supplier

The Importance of Choosing the Right Square Mesh Supplier

In today's industrial and construction landscapes, square mesh materials play a crucial role across a multitude of applications. From construction sites and livestock farming to filtration systems and architectural designs, square mesh provides a versatile solution that meets various functional needs. However, the key to maximizing the benefits of square mesh lies in selecting the right supplier.

Understanding Square Mesh

Square mesh, often made from materials such as stainless steel, aluminum, or plastic, is characterized by its uniform grid pattern. This design allows for effective airflow, drainage, and visibility while ensuring strength and durability. Depending on the wire gauge and the size of the squares, square mesh can serve disparate purposes—from reinforcing structures to preventing the entry of pests in agricultural scenarios.

Why Supplier Choice Matters

When it comes to square mesh, the quality of the product heavily depends on the supplier. A reputable supplier will provide high-quality materials that comply with industry standards, ensuring that the mesh can withstand harsh conditions and perform reliably over time. Poor-quality mesh can lead to structural failures or other issues that not only compromise safety but also lead to significant financial losses.

Furthermore, a good supplier will offer a range of options tailored to specific needs. Different projects require different specifications, such as varying mesh sizes, wire thicknesses, and materials. A supplier with a diverse inventory allows businesses to find the precise mesh product suited for their project without having to compromise on quality or suitability.

Key Factors to Consider

square mesh supplier

When selecting a square mesh supplier, there are several critical factors to consider

1. Reputation and Experience Look for suppliers with a solid track record and years of experience in the industry. Customer reviews and testimonials can provide insight into their reliability and product quality.

2. Quality Assurance Ensure that the supplier adheres to quality control measures and industry standards. Certifications can serve as indicators of the quality of the materials they provide.

3. Customization Capabilities Each project is unique. A supplier that offers customization options can help cater to specific requirements, giving you more control over your final product.

4. Timely Delivery In construction and industrial operations, time is often of the essence. Choose a supplier that has a reputation for maintaining timely deliveries, so your projects are not held up due to material shortages.

5. Customer Support A responsive and knowledgeable customer service team can enhance your purchasing experience. They can assist with product selection, offer advice, and address any issues that may arise.

Conclusion

In summary, the choice of a square mesh supplier is a pivotal element that can influence the success of a project. Prioritizing quality, customization, and reliability will yield better outcomes and satisfaction. As industries evolve, staying informed about the best suppliers in the market becomes increasingly important. By conducting thorough research and considering the factors mentioned above, you can ensure that you partner with the right square mesh supplier, setting the foundation for successful and efficient project execution.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025