-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 04, 2024 11:49 Back to list

Square Wire Mesh Production for Various Applications by Leading Manufacturer

The Rise of Square Wire Mesh Manufacturers A Comprehensive Overview

In the ever-evolving world of manufacturing, square wire mesh has taken its place as a crucial component across various industries. From construction and agriculture to industrial applications and residential projects, the demand for high-quality square wire mesh continues to grow. This article explores the role of square wire mesh manufacturers, the processes involved in production, and the wide range of applications for this versatile material.

What is Square Wire Mesh?

Square wire mesh is a grid-like structure made from wires arranged at right angles to each other. It is typically produced in various sizes, thicknesses, and materials, such as stainless steel, galvanized steel, aluminum, and plastic. The unique geometric properties of square wire mesh offer strength, durability, and flexibility, making it suitable for diverse applications.

The Role of Square Wire Mesh Manufacturers

Square wire mesh manufacturers play a pivotal role in supplying this essential product to various sectors. These manufacturers are equipped with advanced machinery and technology to produce wire mesh that meets industry standards. Their expertise in material selection, processing techniques, and quality control ensures that the products are reliable and meet the specific needs of their clients.

Production Processes

The manufacturing of square wire mesh involves several key processes, including

1. Material Selection The first step involves choosing the right material, which can vary based on the application. For example, stainless steel is preferred for its corrosion resistance in outdoor applications, while galvanized steel is commonly used in construction for its strength and durability.

2. Wire Drawing The selected metal is drawn into wire forms of desired diameters. This process involves pulling the metal through die holes to reduce its diameter while increasing its length.

3. Welding or Weaving Depending on the type of mesh being produced, the wires can be either welded together at their intersections or woven into a grid pattern. Welding creates a stronger bond, making it suitable for heavy-duty applications, whereas weaving provides a more flexible product.

4. Finishing After the mesh is constructed, it undergoes various finishing processes. These may include galvanizing, coating, or other treatments to enhance its resistance to corrosion and mechanical wear.

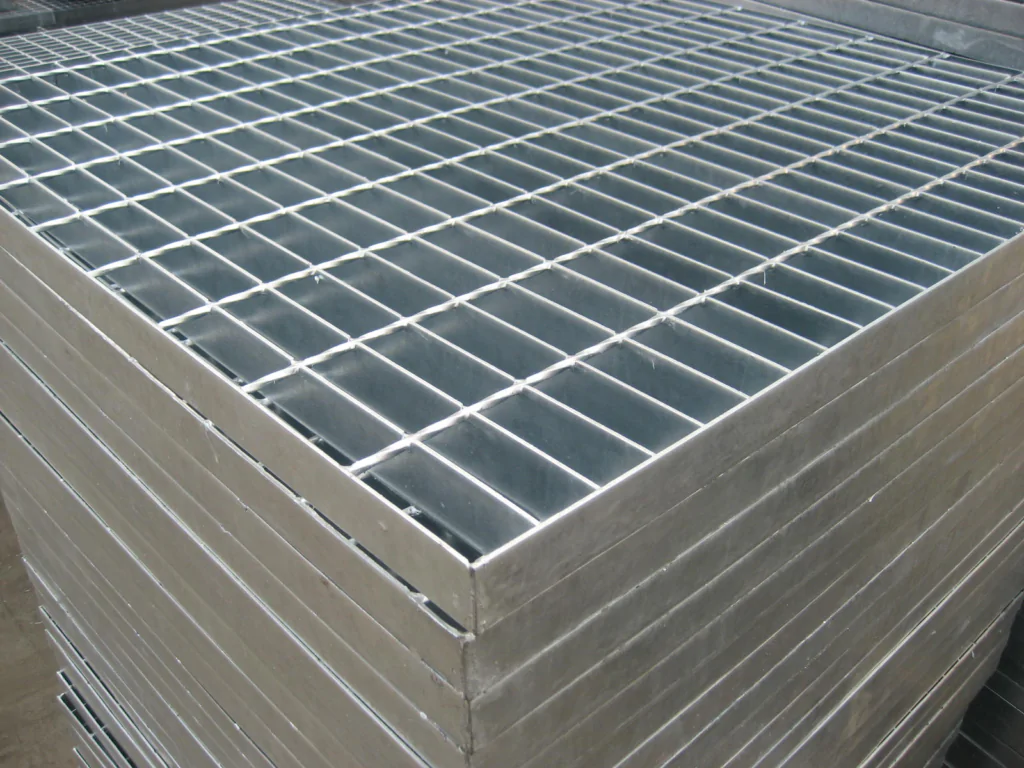

square wire mesh manufacturer

5. Quality Control Manufacturers implement rigorous quality control measures to ensure that the finished products meet the required specifications. This includes testing for strength, durability, and dimensional accuracy.

Applications of Square Wire Mesh

The versatility of square wire mesh means it finds applications in multiple fields

- Construction In the construction industry, square wire mesh is used for reinforcing concrete, fencing, and as a barrier for windows and doors. Its strength helps to enhance the structural integrity of buildings.

- Agriculture Farmers utilize square wire mesh for fencing livestock, creating protective enclosures for plants, and as part of irrigation systems. Its durability and ability to withstand environmental conditions make it ideal for outdoor use.

- Industrial Applications In industrial settings, square wire mesh is used for sorting and filtering processes, conveying materials, and creating safety barriers. It is crucial in industries like mining, oil and gas, and food processing.

- Residential Use Homeowners often use square wire mesh for garden fencing, pet enclosures, and DIY projects. Its ease of installation and adaptability make it a favorite among DIY enthusiasts.

The Future of Square Wire Mesh Manufacturing

As technology advances, the future of square wire mesh manufacturing looks promising. Innovations in materials and production techniques are paving the way for new applications and enhanced performance characteristics. Manufacturers are increasingly adopting automation and smart technologies to improve efficiency and product consistency.

Furthermore, the growing focus on sustainability is influencing the manufacturing processes, with an emphasis on eco-friendly materials and practices. This shift towards responsible manufacturing not only benefits the environment but also attracts clients who prioritize sustainability in their procurement practices.

Conclusion

Square wire mesh manufacturers are an integral part of the supply chain for many industries, providing essential materials that contribute to various applications. As demand continues to rise, these manufacturers are adapting to meet the challenges of modern production while focusing on quality, efficiency, and sustainability. With its endless possibilities, square wire mesh will undoubtedly remain a vital product in the manufacturing sector for years to come.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025