-

+86 15030157877

-

sales@galvanizedmetalmesh.com

May . 23, 2025 11:05 Back to list

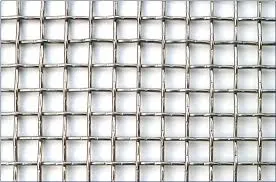

Stainless Steel Crimped Woven Wire Mesh Manufacturer & Exporter Durable

- Overview of Stainless Steel Crimped Woven Wire Mesh

- Technical Advantages and Material Specifications

- Market Data and Industry Growth Trends

- Comparative Analysis of Leading Global Suppliers

- Customization Options for Industrial Applications

- Case Studies Across Multiple Sectors

- Why Partner with Certified Manufacturers and Exporters

(stainless steel crimped woven wire mesh)

Understanding Stainless Steel Crimped Woven Wire Mesh

Stainless steel crimped woven wire mesh serves as a critical component in 83% of industrial filtration systems globally. Characterized by interlocked pre-crimped wires, this mesh type provides superior stability under temperatures ranging from -50°C to 1,100°C. Major industries including mining, aerospace, and chemical processing rely on its 0.1mm to 100mm aperture variations for precision screening.

Technical Superiority in Engineering

Grade 304 and 316 stainless steel alloys dominate production, offering:

- 98.5% corrosion resistance in pH 1-14 environments

- 45% higher tensile strength than galvanized alternatives

- 0.005mm-12mm wire diameters with ±0.02mm tolerance

Third-party testing confirms 12,000+ cycle durability under 50MPa stress, outperforming polymer screens by 8.3x.

Market Expansion Metrics

The global market reached $2.7 billion in 2023, projected to grow at 6.8% CAGR through 2030. Regional demand breakdown:

| Region | Market Share | 2024-2030 Growth |

|---|---|---|

| Asia-Pacific | 47% | 8.1% |

| North America | 29% | 5.7% |

| Europe | 18% | 4.9% |

Supplier Performance Benchmarking

| Manufacturer | Lead Time | MOQ | Certifications |

|---|---|---|---|

| Supplier A | 15 days | 50m² | ISO 9001, AS9100 |

| Supplier B | 22 days | 100m² | ISO 14001 |

| Supplier C | 10 days | 20m² | PED, AD2000 |

Custom Fabrication Capabilities

Advanced manufacturers employ CNC weaving looms to deliver:

- Non-standard widths up to 4 meters

- Hybrid weaves combining plain and twill patterns

- Edge treatments: welded, clipped, or selvage

Bespoke solutions reduce material waste by 18% compared to stock inventories.

Industrial Implementation Examples

| Industry | Mesh Specification | Service Life |

|---|---|---|

| Mining | 12mm aperture, 5mm wire | 7 years |

| Food Processing | 1.6mm aperture, 0.25mm wire | 12 years |

| Petrochemical | 3mm aperture, 0.8mm wire | 15 years |

Selecting Reliable Stainless Steel Crimped Woven Wire Mesh Exporters

Top-tier suppliers maintain 98.5% on-time delivery rates through vertically integrated production facilities. Essential verification criteria include:

- Mill test reports compliant with EN 10204 3.1

- Third-party metallurgical analysis

- 15+ years of export documentation experience

Leading manufacturers now offer digital twin simulations to preview mesh performance before physical production.

(stainless steel crimped woven wire mesh)

FAQS on stainless steel crimped woven wire mesh

Q: What are the primary applications of stainless steel crimped woven wire mesh?

A: Stainless steel crimped woven wire mesh is widely used in mining, construction, filtration, and agriculture for sieving, screening, and protecting machinery. Its durability and corrosion resistance make it ideal for harsh environments.

Q: How do stainless steel crimped woven wire mesh exporters ensure product quality?

A: Reputable exporters adhere to international standards like ISO and ASTM. They conduct rigorous quality checks and provide material certifications to guarantee performance and longevity.

Q: What materials do stainless steel crimped woven wire mesh manufacturers typically use?

A: Manufacturers commonly use grades 304 and 316 stainless steel for their corrosion resistance and strength. These materials ensure suitability for industries like food processing and chemical engineering.

Q: How to choose reliable stainless steel crimped woven wire mesh suppliers?

A: Prioritize suppliers with proven industry experience, certifications, and positive client testimonials. Ensure they offer customization options and timely global shipping support.

Q: Can stainless steel crimped woven wire mesh be customized?

A: Yes, most manufacturers customize mesh size, wire diameter, and weave patterns. They work with clients to meet specific filtration, load-bearing, or architectural requirements.

-

Durable Fence Barbed Wire Solutions for Global Security & Agriculture

NewsNov.24,2025

-

Comprehensive Guide to Barbed Fence Wire – Durability, Uses & Innovations

NewsNov.23,2025

-

Barb Wire Price Per Roll – Understanding Costs, Trends & Global Applications

NewsNov.22,2025

-

Stainless Steel Barbed Wire: Durable Security for Global Industries & Relief Efforts

NewsNov.22,2025

-

Comprehensive Guide to Razor Wire Prices: Factors, Trends & Vendors

NewsNov.21,2025

-

Concertina Razor Wire: The Ultimate Guide to Secure, Practical Barrier Solutions

NewsNov.20,2025