-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 26, 2024 00:36 Back to list

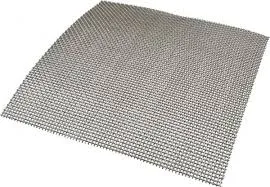

Suppliers of Stainless Steel Crimped Woven Wire Mesh for Various Applications

Choosing the Right Stainless Steel Crimped Woven Wire Mesh Supplier

In today’s industrial landscape, the demand for high-quality stainless steel crimped woven wire mesh is ever-increasing. This versatile material is utilized in a multitude of applications, ranging from filtration systems and sieving to architectural designs and safety applications. As a result, finding a reliable supplier of stainless steel crimped woven wire mesh is crucial for businesses looking to maintain quality and efficiency in their operations. This article will explore the key considerations when selecting a supplier, as well as the benefits of utilizing crimped wire mesh.

Understanding Stainless Steel Crimped Woven Wire Mesh

Stainless steel crimped woven wire mesh is characterized by its unique crimped design, where wires are woven together in a way that enhances their strength and rigidity. This mesh is popular for its durability, resistance to corrosion, and ability to withstand extreme temperatures. It is commonly used in various industries, including mining, agriculture, food processing, and construction.

Key Considerations for Choosing a Supplier

1. Quality of Materials The first thing to look for in a supplier is the quality of their stainless steel. The material should be of high grade, such as 304 or 316 stainless steel, which offers excellent corrosion resistance. Inquire about the source of their materials and whether they comply with industry standards.

2. Manufacturing Capabilities A reliable supplier should have robust manufacturing capabilities, including the latest technology for crimping and weaving. Understand their production process and whether they can accommodate custom orders or specific dimensions to meet your requirements.

3. Experience and Reputation Choose a supplier with a solid reputation in the industry. Look for companies with extensive experience in manufacturing and supplying crimped wire mesh. Reading customer reviews or case studies can provide insight into their reliability and quality of service.

4. Certifications and Compliance Check if the supplier holds any certifications, such as ISO 9001, which indicates their commitment to quality management systems. Compliance with safety and regulatory standards is also essential, particularly if the application involves food safety or medical use.

stainless steel crimped woven wire mesh supplier

5. Customer Support and Service Good customer service is vital when selecting a supplier. Make sure they have a dedicated support team to assist with inquiries, orders, and any issues that may arise. A supplier that prioritizes customer relations will be more likely to address your needs effectively.

6. Pricing and Delivery While cost should not be the only determining factor, it’s essential to ensure that the pricing is competitive. Discuss delivery options and timeframes to ensure that they can meet your project deadlines without compromising quality.

7. Post-Sale Support Finally, inquire about the post-sale support the supplier offers. The ability to access technical assistance or guidance post-purchase can be crucial, especially when integrating the wire mesh into your applications.

Benefits of Using Stainless Steel Crimped Woven Wire Mesh

Utilizing stainless steel crimped woven wire mesh offers several advantages. Firstly, its strength and durability make it suitable for a wide range of demanding applications. It is resistant to rust and corrosion, making it ideal for industries exposed to harsh environments. Moreover, the various mesh sizes and crimping designs allow for customization, enabling users to select the best option for their specific needs.

Additionally, crimped wire mesh enhances airflow and fluid transfer while maintaining structural integrity, making it an excellent choice for filtration and separation processes. Its aesthetic appeal also allows it to be used in decorative applications, such as architectural facades or interior design elements.

Conclusion

Selecting the right stainless steel crimped woven wire mesh supplier can significantly impact the success of your projects. By considering factors such as material quality, manufacturing capabilities, and customer service, you can ensure that you are partnering with a reliable supplier. The benefits of crimped wire mesh—ranging from durability to versatility—make it an indispensable material for numerous industries. With the right supplier by your side, you can harness the full potential of this exceptional product.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025