-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 06, 2024 20:30 Back to list

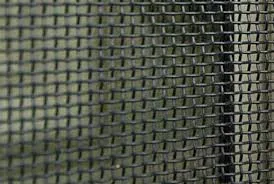

stainless steel wire mesh factory

The Stainless Steel Wire Mesh Factory A Gateway to Quality and Durability

In today's industrial landscape, the demand for high-quality materials is ever-increasing. Among these materials, stainless steel wire mesh has gained significant attention due to its versatility, strength, and resistance to corrosion. A stainless steel wire mesh factory plays a crucial role in meeting this demand, providing various industries with products that contribute to their operational efficiency and safety.

Understanding Stainless Steel Wire Mesh

Stainless steel wire mesh is manufactured from woven strands of stainless steel, which offers exceptional durability and resistance to rust, making it suitable for a wide array of applications. This mesh is commonly used in industries such as construction, food processing, pharmaceuticals, and automotive manufacturing. Its unique properties, including high tensile strength and versatility, allow it to be tailored to meet specific requirements, thereby increasing its value in various applications.

The Manufacturing Process

The production of stainless steel wire mesh involves several steps that ensure the final product meets stringent quality standards. It begins with the selection of high-grade stainless steel wire, which is essential for achieving the desired properties. The wire is then drawn to the required diameter, followed by the weaving process, where the strands are interconnected to create the mesh structure. There are various weaving techniques, including plain weave, twill weave, and Dutch weave, each offering different levels of filtration and strength.

Once woven, the mesh undergoes quality control checks to identify any defects and ensure consistency in standards. This process might include testing for tensile strength, corrosion resistance, and dimensional accuracy. Only after meeting these quality benchmarks is the stainless steel wire mesh cut to size, packaged, and prepared for shipment.

The Role of Technology in Production

stainless steel wire mesh factory

Modern stainless steel wire mesh factories leverage advanced technology to enhance productivity and efficiency. Automated machinery can significantly reduce labor costs and improve accuracy in the weaving process. Furthermore, computer-aided design (CAD) software allows manufacturers to create detailed designs and prototypes, ensuring that the finished product aligns with customer specifications. The implementation of these technologies not only streamlines the manufacturing process but also bolsters the factory's ability to cope with high demand and tight deadlines.

Sustainability and Environmental Considerations

In an era where environmental sustainability is paramount, stainless steel wire mesh factories are also adapting their practices to minimize their ecological footprint. Stainless steel itself is a sustainable material; it is 100% recyclable and can be reused without losing its properties. Many factories are implementing greener manufacturing practices by reducing waste, using energy-efficient machinery, and recycling scrap materials. By prioritizing sustainability, these factories not only contribute positively to the environment but also appeal to environmentally conscious consumers.

Applications Across Industries

The versatility of stainless steel wire mesh makes it indispensable across various sectors. In the food processing industry, it ensures hygiene and safety by acting as a barrier against contaminants while allowing for optimal airflow. In construction, it is used for reinforcement purposes, enhancing the structural integrity of buildings. The pharmaceutical sector utilizes it for filtration processes, ensuring the purity of products. Each application highlights the mesh's ability to cater to industry-specific requirements, emphasizing the importance of a reliable manufacturer.

Conclusion

Stainless steel wire mesh factories are vital to modern industry, providing essential materials that enhance safety, efficiency, and sustainability. As the demand for durable and high-quality products continues to grow, these factories will play an increasingly important role in shaping the future of manufacturing. By embracing technology and sustainability, they are not only meeting current market demands but also paving the way for innovative solutions that will benefit various sectors for years to come. Whether it’s for industrial, commercial, or consumer use, the significance of stainless steel wire mesh cannot be overstated, making its production a key component in achieving durability and quality in numerous applications.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025