-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 03, 2024 18:25 Back to list

Top Manufacturers of Steel Bridge Grating Solutions for Various Applications

Steel Bridge Grating Manufacturers An Overview

Steel bridge grating plays a crucial role in infrastructure, serving as a vital component in the construction and maintenance of bridges. These gratings, often made from steel, provide essential support and stability while allowing for efficient drainage and visibility beneath the bridge. As urbanization increases and infrastructure ages, the demand for quality steel bridge grating is on the rise, leading to a burgeoning market for manufacturers in this niche sector.

When selecting a steel bridge grating manufacturer, several factors should be taken into consideration. One of the foremost is the material quality. High-grade steel, typically galvanized for corrosion resistance, is essential for ensuring longevity and safety. Manufacturers often employ different types of steel, including carbon steel, stainless steel, and alloy steel, each offering distinct advantages depending on the specific environment and load requirements of the bridge.

The manufacturing process itself is another critical aspect to consider. Leading manufacturers utilize advanced technologies such as CNC cutting, welding, and surface treatment techniques to produce gratings that meet stringent engineering standards. Quality control is paramount; therefore, reputable manufacturers adhere to international standards such as ASTM and ANSI to ensure their products are both durable and reliable.

In addition to quality, customization is increasingly important in the industry. Different bridges require different types of gratings based on length, width, load-bearing capacity, and environmental conditions. Manufacturers that offer tailored solutions can better meet the specific needs of their clients. For instance, some manufacturers provide grating with anti-slip surfaces for increased safety, while others may focus on lighter weight designs for easier installation.

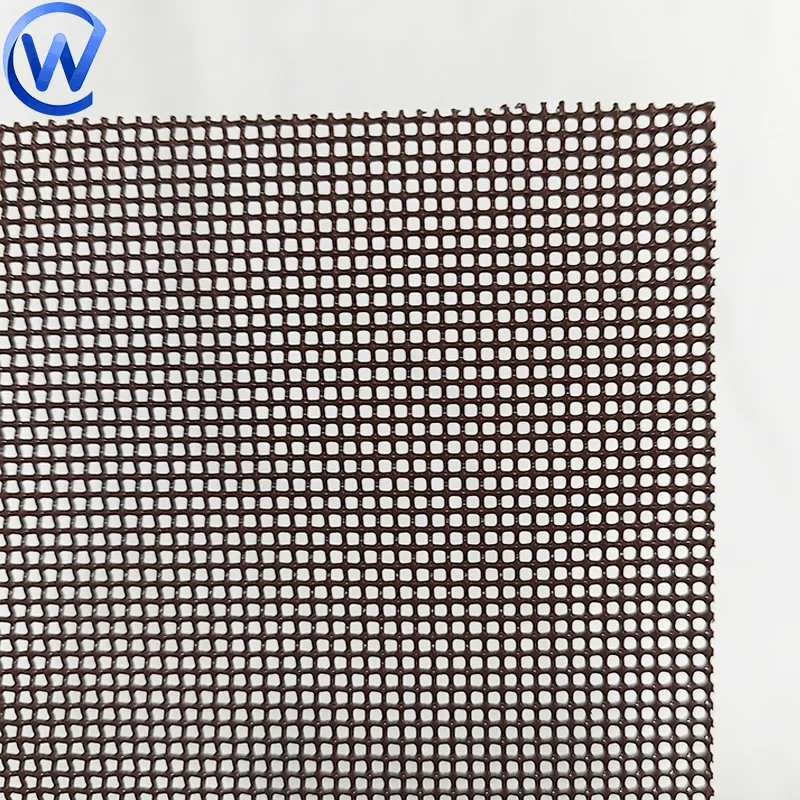

steel bridge grating manufacturers

Moreover, sustainable practices are becoming a significant consideration in the manufacturing process. With growing environmental concerns, many manufacturers are now prioritizing eco-friendly materials and energy-efficient production methods. The use of recycled steel and less energy-intensive processes not only benefits the environment but can also reduce costs, making these products more appealing to cost-conscious customers.

Another important factor is the level of customer service provided by the manufacturers. Good communication and support throughout the project lifecycle—from initial consultation and design to production and post-installation service—can significantly enhance a client’s experience. Manufacturers that take the time to understand their clients' unique requirements and provide ongoing support help build long-lasting relationships in the industry.

When it comes to market competition, the landscape is quite dynamic. Numerous steel bridge grating manufacturers operate globally, each vying for a share of the market. This competition fosters innovation and improvements in product offerings, leading to better quality and more options for consumers. Manufacturers that can combine quality, customization, sustainability, and excellent customer service will likely thrive in this competitive environment.

To summarize, steel bridge grating manufacturers play an integral role in modern infrastructure development. As the demand for durable, custom solutions grows, manufacturers must prioritize quality materials, advanced production techniques, and sustainable practices. By focusing on customer needs and maintaining high standards, these manufacturers can significantly contribute to the safety and functionality of bridges in urban and rural settings alike. Ultimately, the collaboration between skilled manufacturers and infrastructure developers will lead to enhanced structures that are both efficient and capable of withstanding the test of time.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025