-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 29, 2024 00:55 Back to list

Exploring Leading Factories in Steel Metal Grating Production and Innovation

The Rise of Steel Metal Grating Factories

In recent years, the demand for steel metal grating has surged, driven by advancements in industrial applications, construction, and infrastructure projects. Steel metal grating is extensively used across various sectors, including commercial construction, transportation, and even in residential applications due to its durability and strength. This article explores the significance of steel metal grating factories, the processes involved in their production, and the factors contributing to their growth.

Understanding Steel Metal Grating

Steel metal grating is a versatile and strong material made from high-quality steel, characterized by a grid-like structure that allows light, air, and drainage to pass through while providing robust support. Common applications include flooring, walkways, and safety platforms in industrial settings, as well as decorative elements in modern architecture. The unique properties of steel grating, such as its non-slip surface, resistance to corrosion, and longevity, make it a preferred choice for many engineers and architects.

The Role of Factories in Production

Steel metal grating factories play a crucial role in the manufacturing process. These factories utilize advanced machinery and technology to fabricate grating products that meet diverse industry standards and specifications. The production process typically involves several critical stages

1. Material Sourcing Factories begin by sourcing high-quality steel from trusted suppliers. The type of steel used, whether galvanized or stainless, influences the grating's performance and longevity.

2. Cutting and Shaping Once the materials are procured, they are cut to specific dimensions and shaped accordingly. CNC machines and plasma cutters are often employed to ensure precision and efficiency.

3. Welding The next step involves welding the crossbars to the bearing bars. This is a crucial stage as it provides the structural integrity that steel grating is renowned for. Factories often utilize automatic welding machines for uniformity and strength.

4. Finishing After welding, the grating is subjected to various finishing processes, such as deburring, surface treatment, and coating. This not only enhances aesthetic appeal but also increases resistance to harsh environmental conditions.

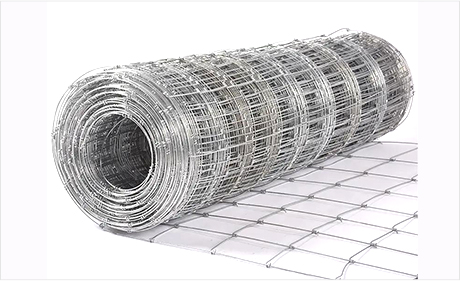

steel metal grating factories

5. Quality Control Before products leave the factory, they undergo rigorous quality control tests to ensure they meet safety standards and specifications. This step is vital to prevent potential failures during use.

Factors Driving Growth

Several factors contribute to the growth of steel metal grating factories

- Infrastructure Development With urbanization and infrastructure projects on the rise, demand for durable and reliable construction materials like steel grating is increasing. Governments and private sectors alike are investing heavily in roads, bridges, and commercial buildings that require such materials.

- Industrial Expansion Industries such as oil and gas, water treatment, and manufacturing are increasingly using steel grating for safety and efficiency. As these industries expand, so does the demand for quality steel grating products.

- Sustainability Practices Many factories are now adopting sustainable practices in their operations, including recycling steel and using eco-friendly coatings. This shift towards sustainability not only appeals to environmentally-conscious consumers but also complies with stricter regulations.

- Technological Advancements The integration of automation and smart technology in manufacturing processes enhances efficiency and reduces labor costs, allowing factories to increase production capacity and reduce lead times.

Conclusion

Steel metal grating factories are essential players in the construction and industrial sectors. Their ability to produce high-quality, durable grating products is crucial to meeting the rising demands of modern infrastructure and safety standards. As the market continues to grow, these factories are poised to benefit from new technologies and increased industrial activities, solidifying their role in shaping the future of construction and safety solutions.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025