-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 08, 2024 16:04 Back to list

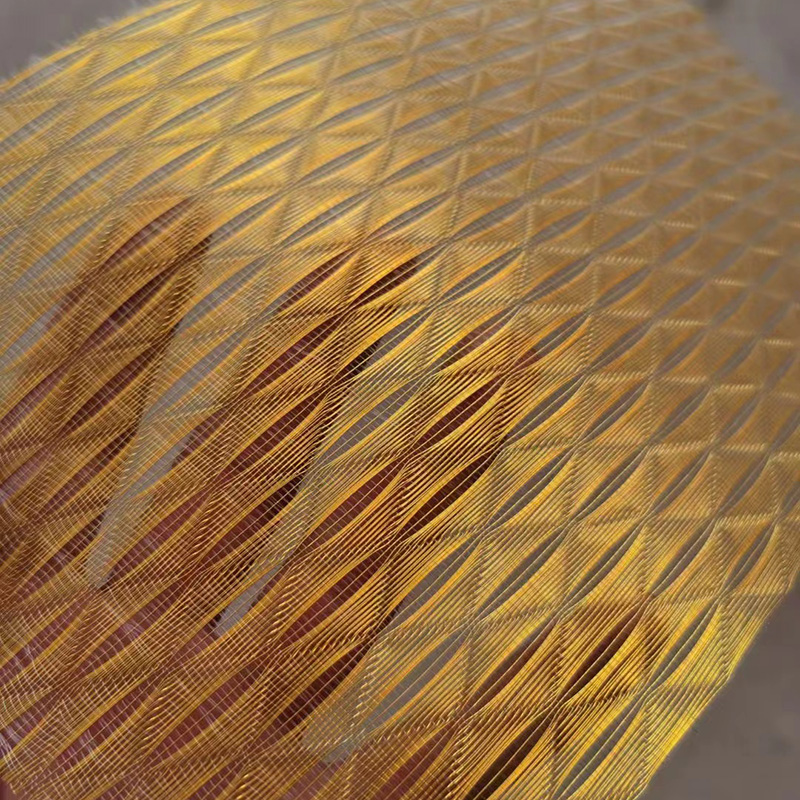

steel metal wire mesh for concrete factory

The Importance of Steel Metal Wire Mesh in Concrete Production

In the construction industry, concrete remains a fundamental building material due to its strength, durability, and versatility. However, to further enhance the properties of concrete and ensure structural integrity, the incorporation of steel metal wire mesh has become increasingly significant. This article explores the vital role that steel metal wire mesh plays in concrete production, specifically in the context of factories that specialize in manufacturing concrete products.

What is Steel Metal Wire Mesh?

Steel metal wire mesh is a grid-like structure made from intersecting steel wires. It is designed in various configurations, including welded, woven, and laser-cut types. The mesh is characterized by its uniform openings and high tensile strength, which provide a reliable reinforcement framework for concrete applications. In factory settings, wire mesh is often pre-fabricated to meet specific project requirements, leading to increased efficiency in concrete placement.

Strength and Durability

One of the primary reasons for using steel wire mesh in concrete is to enhance the material’s structural strength. Concrete, while strong in compression, is relatively weak in tension. This is where steel wire mesh comes into play, as it imparts tensile strength to the concrete matrix. By distributing stresses evenly across the concrete surface, the wire mesh helps prevent the formation of cracks and increases the durability of the final product.

In particular, the use of wire mesh in factory settings allows for the production of concrete that can withstand various loading conditions and environmental pressures. Whether it's for precast concrete panels, slabs, or other components, the presence of steel mesh significantly improves the resistance to bending and shear forces, crucial in load-bearing applications.

Cost Efficiency

Incorporating steel metal wire mesh into concrete production can yield significant cost savings. First, it reduces the amount of concrete required to achieve the necessary strength, which can lower material costs. Secondly, by minimizing the risk of cracking and failure, manufacturers can reduce labor costs associated with repairs and replacements.

Additionally, streamlined manufacturing processes in a factory setting allow for the mass production of wire mesh-reinforced concrete products. This efficiency translates to faster project turnaround times and reduced labor expenses. The ability to pre-fabricate components in controlled environments also leads to improved quality control, a crucial factor in construction.

steel metal wire mesh for concrete factory

Versatile Applications

Steel metal wire mesh is utilized in various concrete applications, making it a versatile option for many projects. In factories that produce concrete products, wire mesh can be found in

1. Precast Concrete Elements These include beams, columns, and wall panels that require robust reinforcement for structural stability. 2. Pavements and Roadways Wire mesh is used in concrete slabs to improve load distribution and prevent cracking, particularly in high-traffic areas.

3. Foundations and Footings The mesh ensures that concrete foundations have the needed tensile strength to support buildings and other structures.

4. Architectural Features In decorative concrete applications, wire mesh can enhance both aesthetics and functionality.

Environmental Considerations

The use of steel metal wire mesh in concrete manufacturing also aligns with sustainability practices. Using less concrete—thanks to enhanced tensile strength—can lead to reduced carbon emissions associated with cement production. Moreover, many manufacturers are now focusing on recyclable materials and environmentally-friendly production techniques, contributing to a more sustainable construction industry.

Conclusion

Steel metal wire mesh serves an indispensable role in the production of concrete within factory settings. By enhancing the strength and durability of concrete products, facilitating cost-effective manufacturing, and allowing for versatile applications, wire mesh has become a cornerstone of modern construction practices. As the construction industry continues to evolve, the integration of innovative materials such as steel wire mesh will undoubtedly shape the future of concrete production, meeting the demands of contemporary architecture and infrastructure while prioritizing sustainability.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025