-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Sep . 03, 2024 04:57 Back to list

twisted soft annealed iron wire factory

Twisted Soft Annealed Iron Wire A Comprehensive Insight into Manufacturing Process

Twisted soft annealed iron wire is a versatile and essential material widely used in various industries, from construction to manufacturing and crafting

. This article delves into the manufacturing process of twisted soft annealed iron wire, emphasizing its significance and applications.The journey of twisted soft annealed iron wire begins with the selection of high-quality raw materials. Iron, in its natural state, is often too hard and brittle for many applications. Thus, the first step in creating soft annealed iron wire is to obtain iron rods that will undergo careful processing. These rods are typically made from iron alloyed with a specific percentage of carbon to achieve desired properties.

After sourcing the raw iron, the next critical step is the annealing process. Annealing involves heating the iron rods to a specific temperature and then allowing it to cool slowly. This process alters the microstructure of the iron, reducing its hardness and brittleness, and making it more pliable and ductile. The result is soft iron, which can be easily twisted and formed without breaking.

Once the annealing process is complete, the softened iron rods are drawn into wire. Drawing is a process where the iron is pulled through a series of dies that progressively reduce the diameter of the wire. This step is crucial as it not only results in the desired thickness of the wire but also enhances its strength and uniformity. The wire is often drawn to various gauges, depending on the intended application.

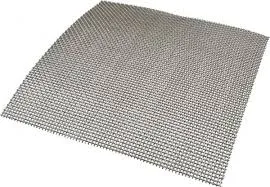

twisted soft annealed iron wire factory

After the drawing process, the next stage involves twisting the iron wire. Twisting enhances the wire's mechanical properties and increases its tensile strength. The twisting process can vary from simple two-strand twists to more complex braiding techniques, depending on the requirements of the end product. The resulting twisted wire is not only stronger but also more resilient, making it highly suitable for various applications.

One of the key advantages of twisted soft annealed iron wire is its adaptability. It is used in numerous sectors such as construction for reinforcing materials, in agriculture for fencing, and in crafting for DIY projects. Its malleability allows it to be easily shaped into hooks, nails, and other hardware items. Moreover, the twisted configuration provides superior strength compared to its non-twisted counterparts, making it ideal for demanding applications.

The finishing touches on twisted soft annealed iron wire involve coating and surface treatment to enhance its durability. Common treatments include galvanization or applying protective coatings to prevent rust and corrosion, thereby increasing its lifespan when exposed to outdoor conditions.

In conclusion, the manufacturing of twisted soft annealed iron wire is a meticulous process that transforms raw iron into a versatile material suitable for various applications. Its unique properties, arising from the annealing and twisting processes, make it indispensable in numerous industries. As industries continue to innovate, the demand for high-quality twisted soft annealed iron wire will undoubtedly remain strong, solidifying its place as a fundamental material in both industrial and artisanal contexts.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025