-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 17, 2024 08:34 Back to list

welded mesh roll manufacturers

Understanding Welded Mesh Roll Manufacturers

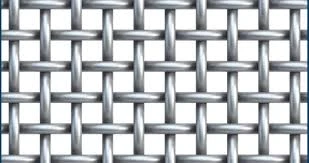

Welded mesh rolls are essential materials used in a wide range of construction and industrial applications. They are made from high-quality steel wires that are welded together to form a grid pattern, offering superior strength and durability. This article seeks to provide insights into welded mesh roll manufacturers, their processes, product varieties, and the significance of selecting the right supplier.

The Manufacturing Process

The manufacturing of welded mesh rolls begins with the raw materials, typically low-carbon steel wires. These wires are drawn to specific diameters, ensuring they meet the required tensile strength. The process of welding the wires involves precision and skill. Using advanced machinery, manufacturers create a mesh grid by intersecting horizontal and vertical wires at set intervals. These intersections are then welded together using either resistance welding or fusion welding techniques, ensuring that the bonds are strong and uniform.

Once the welding is complete, the mesh is cut into rolls of specified lengths and widths. It is also subjected to various treatments to enhance its corrosion resistance. For instance, galvanization is a common method that involves coating the mesh with zinc, thus preventing rust and extending its lifespan. Manufacturers may offer different finishes, including PVC coating, to cater to diverse customer needs.

Types of Welded Mesh Rolls

Welded mesh rolls come in various types, each designed for specific applications. Common varieties include

1. Standard Welded Wire Mesh This type is widely used in construction for reinforcing concrete. Its robust structure provides enhanced load-bearing capacity.

2. Animal Enclosures Welded mesh rolls can serve as effective fencing solutions for farms, zoos, and other facilities requiring animal containment. These rolls are designed to withstand harsh environmental conditions and protect against wildlife.

3. Civil Engineering In civil engineering projects, welded mesh is utilized for roadworks, sloped structures, and landscaping. It assists in stabilizing soil and preventing erosion.

4. Architectural Applications Welded mesh is also popular in architecture and design, used in balustrades, facades, and other decorative elements due to its aesthetic appeal.

welded mesh roll manufacturers

5. Industrial Uses In the industrial sector, these mesh rolls can be employed for safety barriers, storage racks, and shelving solutions. Their durability and versatility make them ideal for a variety of applications.

Selecting the Right Manufacturer

Choosing the right welded mesh roll manufacturer is crucial for ensuring product quality and reliability. Here are some key factors to consider

1. Reputation Look for manufacturers with a solid reputation in the industry. Reviews and testimonials can provide insights into their reliability and product quality.

2. Quality Standards Ensure that the manufacturer adheres to international and national quality standards, such as ISO certifications. This guarantees that the products meet specific performance criteria.

3. Product Range A good manufacturer should offer a diverse range of mesh products to accommodate various applications. This flexibility can be beneficial for customers with unique requirements.

4. Customization Options Many applications necessitate customized sizes, wire diameters, and finishes. Look for manufacturers that offer tailor-made solutions to meet your specific needs.

5. Customer Support Efficient customer service is essential. A responsive manufacturer will assist you in making informed decisions and address any issues promptly.

6. Pricing While cost should not be the sole determining factor, it is essential to compare prices among different manufacturers. Look for a balance between quality and affordability.

Conclusion

Welded mesh rolls play a critical role in construction, agriculture, and various industrial sectors. The manufacturers of these products are pivotal in ensuring their quality and suitability for intended applications. When selecting a welded mesh roll manufacturer, consider their reputation, product range, customization options, and support services. By making an informed choice, businesses and individuals can ensure they are investing in reliable and durable products that meet their specific needs. The right welded mesh can significantly impact project success, contributing to enhanced safety and efficiency in the long run.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025