-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 07, 2024 20:50 Back to list

Suppliers of Welded Panels for Various Applications and Industries

Welded Panel Suppliers Key Players in Modern Construction

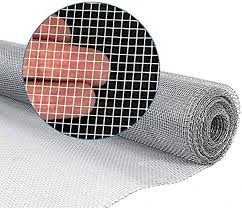

In the realm of construction and manufacturing, welded panels have emerged as a crucial component in the creation of durable and robust structures. These panels, often composed of metal or a combination of materials, are joined together through welding processes, providing strength and stability that are essential in various applications. As such, the role of welded panel suppliers in the industry has become increasingly significant.

Understanding Welded Panels

Welded panels are flat structures made from metal sheets that are fused together through welding techniques. The materials used can range from mild steel and aluminum to advanced alloys, each offering distinct advantages in terms of weight, strength, and resistance to environmental factors. These panels are extensively used in industries such as construction, automotive, aerospace, and more, playing a vital role in the manufacture of everything from building facades and structural supports to vehicle chassis and machinery components.

The Importance of Quality Suppliers

Choosing the right welded panel supplier is crucial for any project. Quality and specifications directly impact the final product's safety, durability, and compliance with regulatory standards. Reputable suppliers prioritize the use of high-grade materials and incorporate stringent quality control processes to ensure that their panels can withstand the rigors of the intended application. They often possess certifications, such as ISO or ASTM, which reaffirm their commitment to quality and adherence to industry standards.

Factors to Consider When Selecting Suppliers

1. Material Expertise Different projects necessitate different materials. Suppliers should have expertise in a variety of metals and alloys to accommodate the specific needs of diverse applications.

2. Welding Technology The type of welding method used can affect the integrity of the panels. Suppliers who employ advanced welding techniques, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding, tend to produce higher quality products.

welded panel suppliers

3. Customization Options Many projects require tailored solutions. A good supplier should offer customization services, allowing clients to specify dimensions, shapes, and additional features that meet their unique project requirements.

4. Delivery and Lead Times Timeliness is often as crucial as quality. Suppliers that can offer quick turnaround times while maintaining quality standards can significantly benefit projects with tight deadlines.

5. After-Sales Support Reliable after-sales support is essential, especially for large projects. Suppliers should offer assistance for installation, maintenance, and any potential issues that arise post-purchase.

Trends in the Industry

The demand for welded panels has evolved alongside advancements in technology and construction protocols. One notable trend is the increasing use of automation and robotic welding techniques, which enhance precision and efficiency. Additionally, there is a growing emphasis on sustainability, prompting many suppliers to seek eco-friendly materials and practices in their production processes.

Furthermore, the construction industry is gradually shifting towards modular building techniques, where prefabricated welded panels play a significant role. This method not only speeds up construction timelines but also minimizes waste, further emphasizing the need for quality welded panel suppliers who can provide reliable, versatile products.

Conclusion

The role of welded panel suppliers is indispensable in the construction and manufacturing landscape. With their ability to deliver quality, durability, and customization, these suppliers are key partners in ensuring the successful execution of projects across various industries. As construction trends continue to evolve, the need for innovative and reliable welded panel suppliers will only increase, driving advancements in material technology and production practices. Consequently, companies must carefully evaluate potential suppliers to ensure their projects meet the highest standards of quality and performance.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025