-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 10:47 Back to list

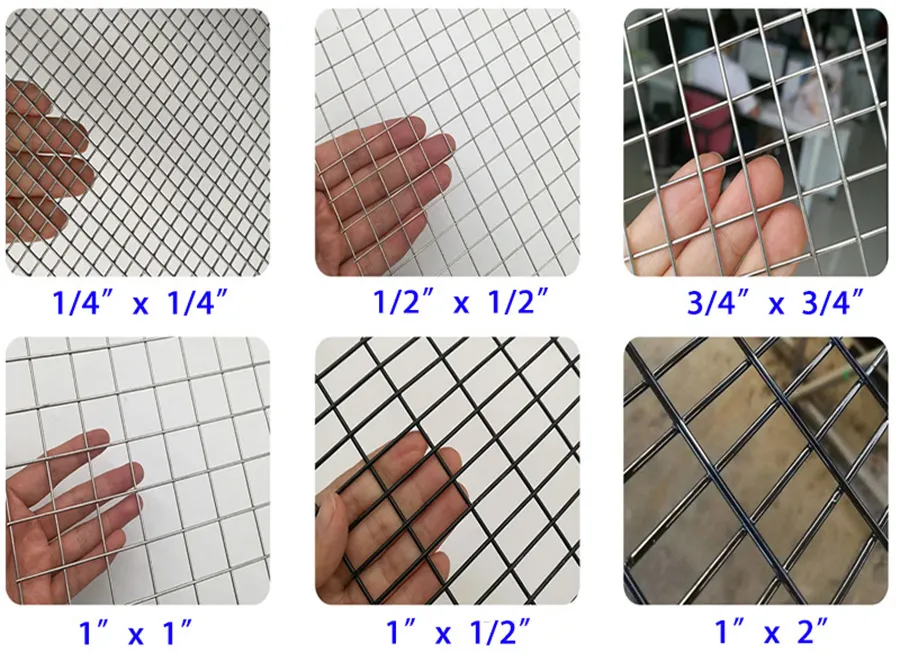

galvanized welded wire mesh

Wire mesh, a versatile and durable product, is an essential component across various industries, thanks to its extensive range of applications and the robust features it offers. For professionals seeking reliability and quality, wire mesh provides a compelling solution that marries both functionality and expertise. This article explores the advantages of wire mesh and delivers insights from industry experts to enhance your understanding and utilization of this remarkable product.

Security and safety are critical areas where wire mesh demonstrates considerable authority. In the realm of security fencing, wire mesh serves as a formidable barrier, deterring unauthorized access while maintaining visibility. Its application in safety gear, such as protective gloves and face shields, further underscores its trustworthiness in safeguarding workers. Industries heavily invest in safety equipment made of wire mesh, assured by its protective qualities and the peace of mind it provides. Moreover, wire mesh manufacturers hold a distinguished reputation for customer support and service excellence. Trustworthy suppliers maintain rigorous quality control checks and adhere to international standards, cementing their reputation as reliable partners in various business ventures. By choosing certified and reputed wire mesh providers, businesses align themselves with products that uphold integrity, performance, and sustainability. In today's competitive landscape, securing a supplier who prioritizes specialization and excellence in wire mesh production is essential. Investing in expertly crafted wire mesh translates to enhanced project outcomes, superior safety features, and long-term client relationships grounded in trust and respect. In conclusion, wire mesh is not just a product; it embodies a synthesis of experience, expertise, authority, and trust. For those in construction, agriculture, and beyond, incorporating wire mesh into your operations ensures a robust, versatile, and dependable solution that serves a myriad of practical applications with excellence and integrity.

Security and safety are critical areas where wire mesh demonstrates considerable authority. In the realm of security fencing, wire mesh serves as a formidable barrier, deterring unauthorized access while maintaining visibility. Its application in safety gear, such as protective gloves and face shields, further underscores its trustworthiness in safeguarding workers. Industries heavily invest in safety equipment made of wire mesh, assured by its protective qualities and the peace of mind it provides. Moreover, wire mesh manufacturers hold a distinguished reputation for customer support and service excellence. Trustworthy suppliers maintain rigorous quality control checks and adhere to international standards, cementing their reputation as reliable partners in various business ventures. By choosing certified and reputed wire mesh providers, businesses align themselves with products that uphold integrity, performance, and sustainability. In today's competitive landscape, securing a supplier who prioritizes specialization and excellence in wire mesh production is essential. Investing in expertly crafted wire mesh translates to enhanced project outcomes, superior safety features, and long-term client relationships grounded in trust and respect. In conclusion, wire mesh is not just a product; it embodies a synthesis of experience, expertise, authority, and trust. For those in construction, agriculture, and beyond, incorporating wire mesh into your operations ensures a robust, versatile, and dependable solution that serves a myriad of practical applications with excellence and integrity.

Latest news

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025