-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Jan . 09, 2025 11:47 Back to list

Welded Wire Mesh

Wire mesh, an often-overlooked component in industrial applications, serves as the silent hero behind countless infrastructures and products we rely on daily. Its applications span a wide range of industries, each with specific requirements and contexts that highlight the versatility and critical importance of this material. Understanding its unique qualities and applications from an expert's perspective can illuminate why wire mesh is not just a simple tool but a cornerstone of modern manufacturing and construction.

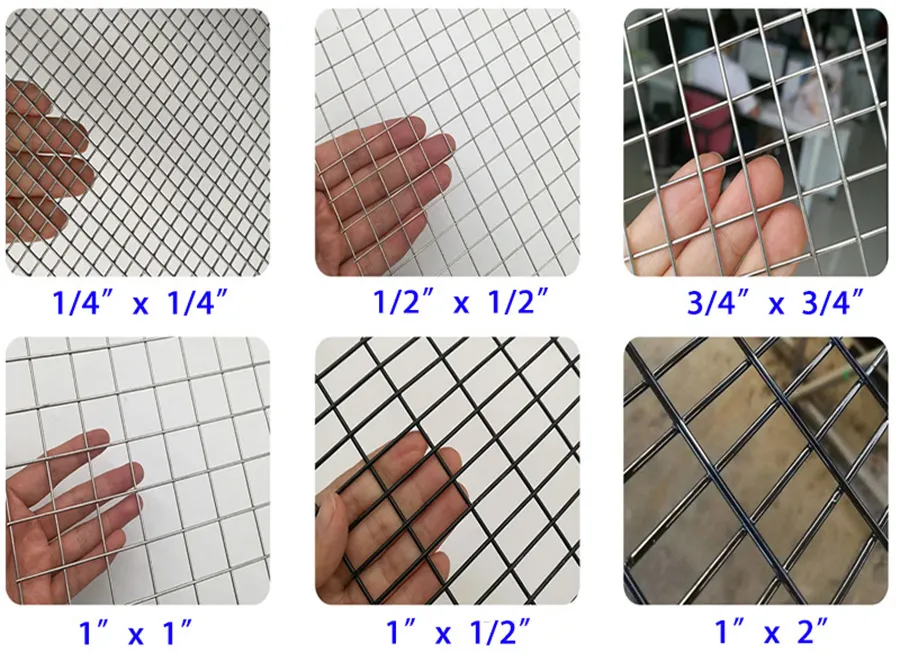

In agriculture, wire mesh plays a crucial role in ensuring the security and management of livestock and crops. Its durability and resistance to environmental factors make it ideal for fencing and enclosure systems. Farmers and agricultural specialists use wire mesh not only as a protective barrier but also as a support for plant growth, showcasing its versatility. High-quality wire mesh is engineered to withstand corrosion and damage from exposure to weather, ensuring longevity and reliability in agricultural applications. Professionals in these various fields highlight the importance of selecting the right type of wire mesh to match specific requirements. Factors such as material type (stainless steel, galvanized steel, etc.), weave style, and mesh size can significantly impact performance. Industrial experts advocate for a thorough assessment of operational needs accompanied by consultations with reputable wire mesh suppliers to navigate the options effectively. This careful selection process underpins the trust and authority wire mesh commands across diverse applications. In conclusion, wire mesh is much more than the sum of its parts. Its broad spectrum of applications, from construction and architecture to manufacturing and agriculture, underscores its essential role in today’s technological and industrial landscapes. Through the combined expertise and real-world experiences of professionals who work with this material every day, the nuanced qualities and applications of wire mesh are brought to light. Its trustworthiness and authority in these applications attest to its value and indispensability in modern engineering and design. As industries continue to evolve, wire mesh remains a constant, adapting to and supporting the ever-changing needs of society.

In agriculture, wire mesh plays a crucial role in ensuring the security and management of livestock and crops. Its durability and resistance to environmental factors make it ideal for fencing and enclosure systems. Farmers and agricultural specialists use wire mesh not only as a protective barrier but also as a support for plant growth, showcasing its versatility. High-quality wire mesh is engineered to withstand corrosion and damage from exposure to weather, ensuring longevity and reliability in agricultural applications. Professionals in these various fields highlight the importance of selecting the right type of wire mesh to match specific requirements. Factors such as material type (stainless steel, galvanized steel, etc.), weave style, and mesh size can significantly impact performance. Industrial experts advocate for a thorough assessment of operational needs accompanied by consultations with reputable wire mesh suppliers to navigate the options effectively. This careful selection process underpins the trust and authority wire mesh commands across diverse applications. In conclusion, wire mesh is much more than the sum of its parts. Its broad spectrum of applications, from construction and architecture to manufacturing and agriculture, underscores its essential role in today’s technological and industrial landscapes. Through the combined expertise and real-world experiences of professionals who work with this material every day, the nuanced qualities and applications of wire mesh are brought to light. Its trustworthiness and authority in these applications attest to its value and indispensability in modern engineering and design. As industries continue to evolve, wire mesh remains a constant, adapting to and supporting the ever-changing needs of society.

Next:

Latest news

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025