-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Dec . 11, 2024 10:56 Back to list

Innovative Wire Mesh Production Techniques by Leading Manufacturers Worldwide

The Rise of Wire Mesh Factories A Transformative Industry

In the modern industrial landscape, wire mesh factories have emerged as crucial players in the manufacturing sector. These factories design and produce various types of wire mesh, which find applications across a multitude of industries, including construction, agriculture, automotive, and filtration. The increasing demand for wire mesh products, driven by technological advancements and a growing emphasis on durability and efficiency, showcases the evolution and significance of wire mesh factories.

Understanding Wire Mesh

Wire mesh, also known as wire cloth or wire screen, consists of strands of metal wire woven together to create a grid-like structure. The materials used can vary, with stainless steel, aluminum, and galvanized steel being the most common. The versatility of wire mesh allows it to be utilized for various purposes, such as reinforcing concrete, sieving materials, or providing security barriers. The ability to customize the size, shape, and material has made wire mesh an invaluable resource in multiple sectors.

The Manufacturing Process

Wire mesh production involves several crucial steps, starting from raw material selection to the final finishing processes. Initially, high-quality wire is selected based on the intended application. The wire is then processed through machinery that ensures it is cut to standard lengths and wired together in precise configurations.

Once the mesh is created, it undergoes treatments like welding, galvanizing, or coating, enhancing its properties such as corrosion resistance and strength. Finally, quality control measures are implemented to ensure that the products meet the required industry standards before they are dispatched to customers.

Market Trends and Innovations

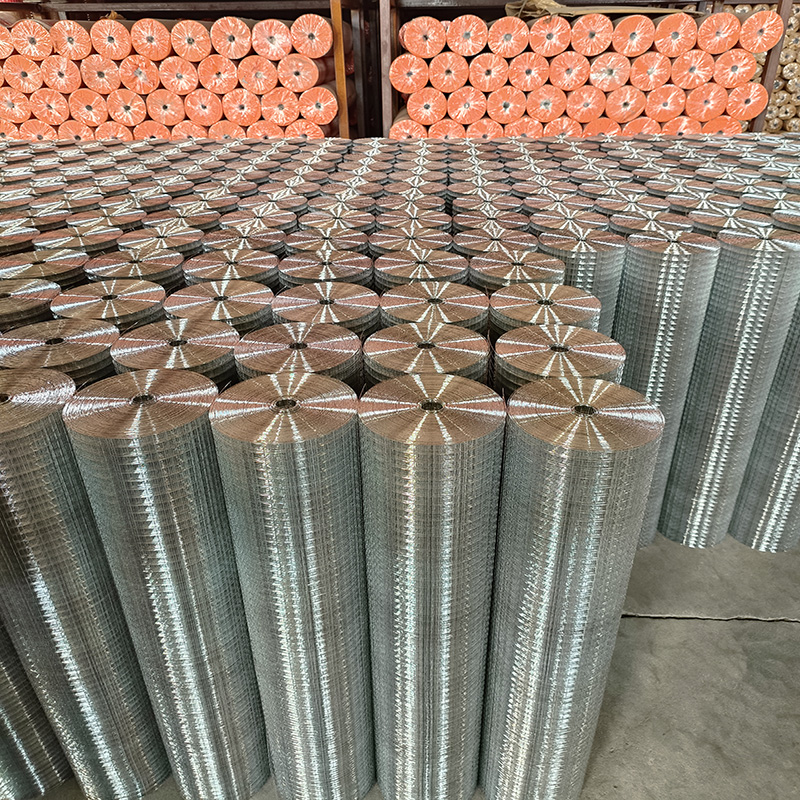

wire mesh factories

The wire mesh industry has witnessed significant growth due to rising demands across various sectors. For instance, in the construction industry, the trend towards using lightweight yet durable materials has spurred the production of specialized wire mesh that reinforces structures while minimizing weight. Similarly, in agriculture, wire mesh is essential for fencing, pest control, and soil retention.

Innovation has played a critical role in the evolution of wire mesh factories. Advanced technologies, such as automated weaving machines and computer-aided design (CAD) systems, have increased production efficiency and allowed for precise customization. The integration of smart manufacturing techniques, such as IoT-enabled machines, has also improved monitoring and optimization of production processes.

Environmental Considerations

As industries become more conscious of their environmental impact, wire mesh factories are adapting to sustainable practices. Many manufacturers are investing in eco-friendly processes that minimize waste and energy consumption. Additionally, the use of recyclable materials in production not only reduces environmental footprints but also appeals to a growing base of eco-conscious consumers.

Conclusion

Wire mesh factories represent a blend of tradition and innovation, playing a pivotal role in supporting a wide array of industries. Their ability to adapt to market demands, embrace new technologies, and implement sustainable practices is a testament to their importance in the contemporary manufacturing landscape. As we move forward, the wire mesh industry is expected to continue evolving, keeping pace with global trends and challenges. Whether it's enhancing construction safety, improving agricultural productivity, or providing essential filtration solutions, the contribution of wire mesh factories to various sectors will only increase, solidifying their position as integral components of industrial supply chains.

In summary, the future of wire mesh factories looks promising, marked by technological advancements and an increasing commitment to sustainability. Their products will continue to be indispensable in everyday applications, shaping the way industries operate and contributing to a more connected, efficient, and environmentally-friendly world.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025