-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 06, 2024 06:12 Back to list

Wire Mesh Manufacturing Solutions for Diverse Industrial Applications and Needs

The Significance of Wire Mesh Factories in Modern Industries

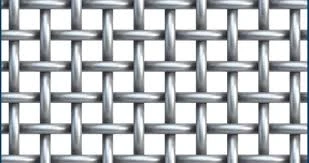

Wire mesh factories play a crucial role in various sectors by providing versatile and high-quality mesh products that cater to diverse applications. Wire mesh, a material made from interconnected wires forming a grid or net, is used across industries ranging from construction to agriculture, filtration, and security systems. This article delves into the importance of wire mesh factories, the processes involved in manufacturing wire mesh, and their various applications.

Manufacturing Processes

The production of wire mesh begins with raw materials, typically high-quality steel or stainless steel wires, which are selected based on the intended use of the mesh. The manufacturing process involves several key steps

1. Wire Drawing This initial step involves reducing the diameter of wire rods by pulling them through a series of dies. The wire is drawn to the desired gauge to ensure strength and flexibility.

2. Weaving After the wires are prepared, they are woven together to create the mesh. Two common types of weaving are plain and twill weaving. In plain weaving, wires are aligned in a simple over-and-under pattern, while twill weaving involves a more complex interlacing, providing greater strength and flexibility.

3. Finishing Treatments Once the mesh is woven, it often undergoes various finishing processes like galvanization, coating, or painting to enhance its durability and resistance to corrosion. These treatments ensure that the wire mesh can withstand environmental challenges and prolong its lifespan.

4. Quality Control Wire mesh factories prioritize quality control to guarantee that their products meet industry standards. Rigorous testing for tensile strength, wire thickness, and mesh dimensions ensures that every batch produced can meet the specific needs of clients.

Applications of Wire Mesh

Wire mesh products have numerous applications across various industries

wire mesh factory

1. Construction In construction, wire mesh is commonly used in flooring, concrete reinforcement, and partition walls. Its strength provides structural integrity and helps prevent cracks in concrete.

2. Agriculture Farmers utilize wire mesh for fencing, protecting livestock, and creating structures for supporting crops. Mesh is also used in greenhouses, enabling sunlight to penetrate while providing a barrier against pests.

3. Filtration Wire mesh plays a vital role in filtration systems, used to separate solids from liquids or gases. This application is crucial in industries such as food processing, water purification, and chemical manufacturing.

4. Industrial Safety In various industrial sectors, wire mesh is used to create safety barriers, machine guards, and grating. This ensures worker safety by minimizing the risk of accidents and injuries.

5. Architecture and Design Wire mesh also finds its place in modern architecture and design, being used in decorative facades, partitions, and architectural features. Its aesthetic versatility allows designers to incorporate it into various styles while maintaining functionality.

Advantages of Wire Mesh

Wire mesh offers several benefits that make it a preferred choice across industries

- Durability Wire mesh is robust and can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. - Customizability Factories can produce wire mesh in various sizes, wire gauges, and configurations, allowing for tailored solutions to meet specific requirements. - Cost-effectiveness The production of wire mesh is efficient, and its longevity translates into reduced maintenance costs, making it a cost-effective choice for many applications.

Conclusion

Wire mesh factories are vital contributors to the industrial ecosystem, providing essential products that enhance safety, efficiency, and functionality across diverse applications. As industries continue to evolve, the demand for high-quality, durable, and customizable wire mesh products will only grow. This underscores the importance of wire mesh factories in keeping pace with technological advancements and the ever-changing needs of our modern world. By prioritizing quality and innovation, these factories ensure that wire mesh remains a cornerstone material across numerous sectors.

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025