-

+86 15030157877

-

sales@galvanizedmetalmesh.com

Nov . 19, 2024 05:23 Back to list

Wire Mesh Solutions for Concrete Manufacturing Industry Suppliers and Producers

The Importance of Wire Mesh for Concrete Manufacturers

In the realm of concrete construction, wire mesh plays a crucial role in ensuring the durability and strength of various structures. As concrete manufacturers continually seek innovative solutions to improve the quality and longevity of their products, the use of wire mesh has become increasingly significant. In this article, we will explore the various benefits of wire mesh, its applications, and why it is an essential component for concrete manufacturers.

Understanding Wire Mesh

Wire mesh is a grid-like structure made from high-quality steel wires that are either welded or woven together. The primary purpose of wire mesh in concrete applications is to provide reinforcement. The steel wires help distribute loads evenly throughout the concrete, reducing the risk of cracking and structural failure. This is particularly important in large-scale concrete projects such as bridges, highways, and commercial buildings, where the demands on the material are significantly higher.

Benefits of Using Wire Mesh

1. Enhanced Structural Integrity One of the most significant advantages of using wire mesh in concrete is its ability to enhance the structural integrity of the material. The inclusion of wire mesh helps to absorb stress, prevent cracking, and ensure that any potential movement within the concrete does not lead to catastrophic failure.

2. Cost-Effective Solution Wire mesh is a cost-effective reinforcement solution. The initial investment in wire mesh can be offset by the long-term savings associated with reduced maintenance and repair costs. By minimizing the likelihood of cracks and structural damage, concrete manufacturers can save on both labor and materials over the lifespan of a project.

3. Improved Load Bearing Capacity Structures reinforced with wire mesh boast improved load-bearing capacity. This is critical in construction projects that demand high levels of strength and support. By reinforcing the concrete, manufacturers can create products that can withstand greater stresses and strains, providing peace of mind for engineers and architects.

4. Versatility in Application Wire mesh is versatile and suitable for a wide range of applications. Whether for residential, commercial, or industrial projects, wire mesh can be used in various forms of concrete, including slabs, walls, and pavements. Its flexibility allows manufacturers to customize their solutions based on specific project requirements.

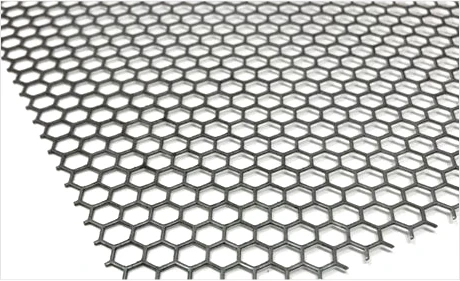

wire mesh for concrete manufacturers

5. Reduction of Shrinkage Cracking Concrete is prone to shrinkage as it cures, which can lead to cracking. The incorporation of wire mesh can significantly reduce the extent of shrinkage cracking, ensuring a smoother finish and extending the lifespan of the concrete product.

Applications of Wire Mesh in Concrete

Wire mesh is utilized in an array of concrete applications, including

- Floor Slabs Wire mesh is commonly used in the reinforcement of floor slabs, ensuring that they can withstand heavy foot traffic and loads.

- Driveways and Pavements For driveways, pavements, and roads, wire mesh provides the necessary strength and durability, allowing these surfaces to resist cracking and wear over time.

- Retaining Walls The use of wire mesh in retaining walls helps maintain stability against lateral earth pressures, preventing collapse and failure.

- Infrastructure Projects Large-scale infrastructure projects, such as bridges and highway overpasses, greatly benefit from the enhanced strength and stability that wire mesh provides.

Conclusion

As concrete manufacturers continue to innovate and improve their products, wire mesh stands out as an indispensable component in the construction process. Its ability to enhance structural integrity, provide cost savings, improve load-bearing capacity, and reduce shrinkage cracking makes it an ideal choice for a multitude of applications. As the demand for durable and reliable concrete solutions grows, the importance of wire mesh in the manufacturing process will undoubtedly continue to rise, positioning it as a key player in the future of construction. Understanding the benefits and applications of wire mesh not only empowers manufacturers but also ensures the safety and reliability of the structures they build.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025