-

+86 15030157877

-

sales@galvanizedmetalmesh.com

aug . 16, 2024 10:02 Back to list

10x10 Stainless Steel Square Wire Mesh Manufacturing Factory Overview

The Importance of 10x10 Stainless Steel Square Wire Mesh in Various Industries

Stainless steel square wire mesh, with a specification of 10x10 , is an essential material utilized across a plethora of industries due to its durability, resistance to corrosion, and versatility. The manufacturing process of this type of wire mesh involves weaving stainless steel wires together to form a grid of 10 openings per inch in both directions, resulting in a robust barrier that meets a range of application requirements.

Composition and Properties

The term 10x10 describes the mesh's specifications, where '10' refers to the number of openings per inch, and ' ' indicates its wire diameter which enhances the mesh's strength. This specification is significant because it offers a balance of openness and strength, making it suitable for various uses from industrial applications to domestic settings.

One of the most notable properties of stainless steel is its corrosion resistance, attributed to the presence of chromium. This feature enables 10x10 stainless steel wire mesh to withstand harsh environmental conditions. As such, it is commonly used in situations where exposure to moisture, chemicals, or extreme temperatures is inevitable. The longevity of this material translates to cost savings, as it requires less frequent replacement compared to other materials like mild steel.

Applications

1. Construction and Architecture In the construction industry, 10x10 stainless steel square wire mesh is often used as reinforcement in walls, floors, and sections of concrete. Its structural integrity ensures that buildings can better withstand pressure and environmental forces, providing safety and durability.

2. Agriculture Farmers utilize stainless steel wire mesh for fencing and protecting crops from pests and animals. Its strength prevents intrusion while allowing for adequate air and sunlight to reach the plants.

10x10 stainless steel square wire mesh factory

3. Mining and Mineral Processing In mining operations, this type of mesh is essential for screening and separating materials efficiently. Its corrosion resistance is crucial in environments where chemicals are often present.

4. Food and Pharmaceutical Industries Safety and hygiene are paramount in these sectors. 10x10 stainless steel wire mesh is used not only to create barriers but also in the fabrication of equipment such as screens, filters, and racks due to its non-reactive nature.

5. Welding and Metal Fabrication The welding industry often relies on this mesh for various applications, including the creation of enclosures and safety barriers. Its fine openings can allow for air passage while still providing a secure structure.

Manufacturing Process

The production of 10x10 stainless steel wire mesh typically begins with high-grade stainless steel wires. These wires are meticulously woven together using automated machinery that ensures precision and consistency in the opening sizes. The resulting mesh is then treated to enhance its properties further, such as through galvanization or additional surface treatments that increase resistance to rust and wear.

Conclusion

In summary, the 10x10 stainless steel square wire mesh represents a vital component in numerous sectors, reflecting its significant contributions to safety, efficiency, and sustainability. Its combination of strength, corrosion resistance, and versatile applications make it a preferred choice among manufacturers and industries alike. As industries continue to evolve, the demand for such high-quality materials will undoubtedly grow, underscoring the importance of this mesh type in future innovations and applications.

-

AI SEO Optimizer

NewsJul.20,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

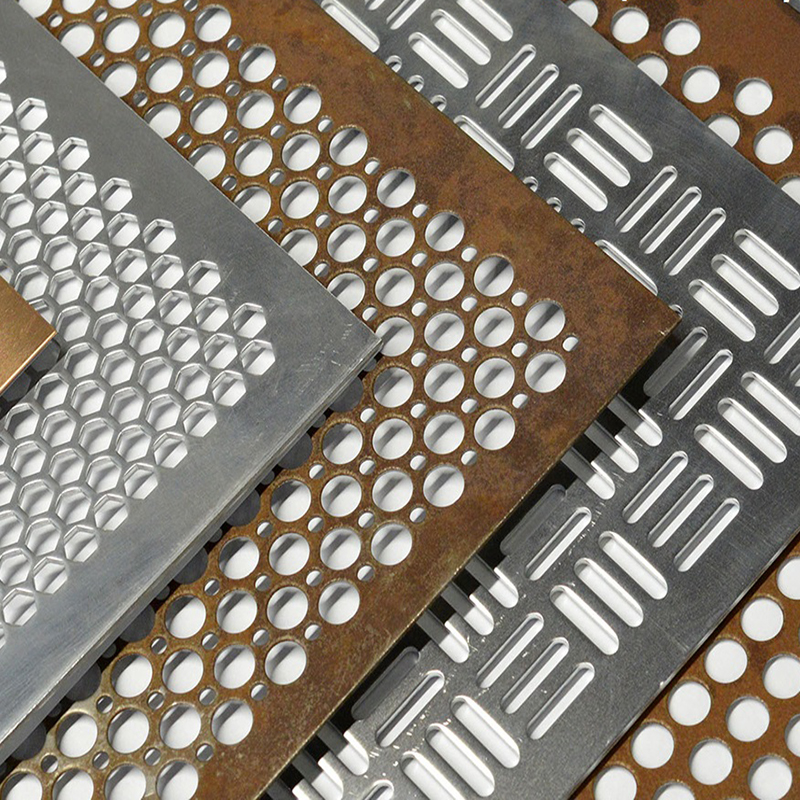

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025