-

+86 15030157877

-

sales@galvanizedmetalmesh.com

okt . 17, 2024 16:39 Back to list

crimped woven mesh

Understanding Crimped Woven Mesh Applications, Benefits, and Manufacturing

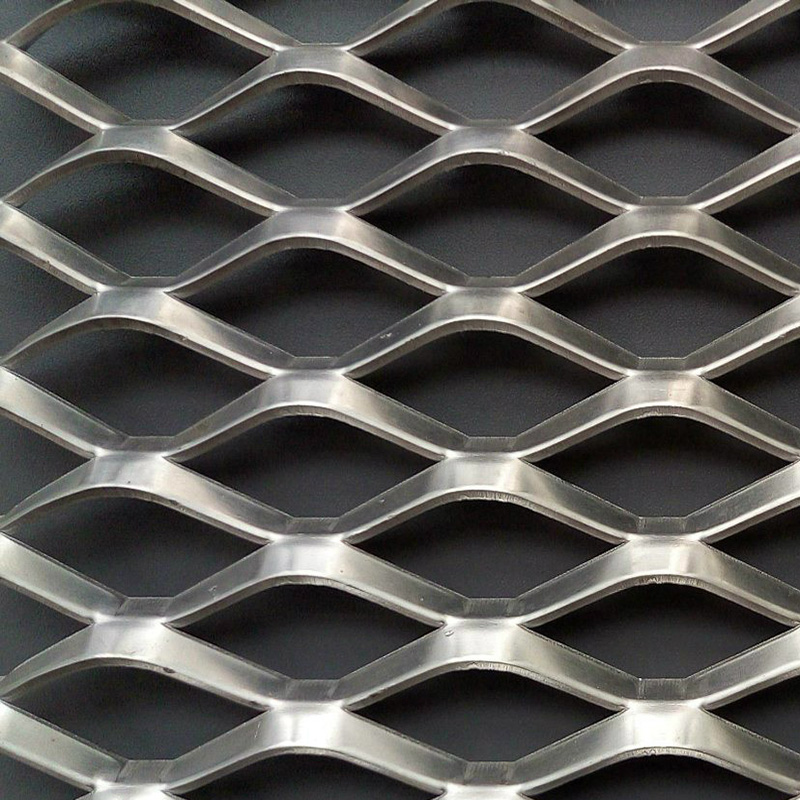

Crimped woven mesh is a versatile material that has garnered attention in various industries due to its unique properties and advantageous characteristics. This specialized mesh is made by creating wavy patterns or crimps in the wire before weaving it into a fabric, which results in a mesh structure that is not only durable but also effective for many applications. In this article, we will explore what crimped woven mesh is, its benefits, and its various applications across different industries.

What is Crimped Woven Mesh?

At its core, crimped woven mesh is constructed from interwoven wires that have been crimped or wavy prior to being woven. The crimping process introduces a degree of flexibility and strength to the wire, allowing it to withstand significant stresses and strain. The weaving pattern, combined with the crimped structure, enhances the mesh's stability and makes it suitable for a variety of applications.

Crimped woven mesh can be made from various materials, including stainless steel, carbon steel, and even synthetic fibers. The choice of material typically depends on the specific application requirements, such as resistance to corrosion, temperature tolerance, and tensile strength.

Benefits of Crimped Woven Mesh

1. Enhanced Strength and Durability One of the key advantages of crimped woven mesh is its increased strength. The crimps in the wire create interlocking points that help dissipate stresses across the mesh, effectively preventing deformation and increasing its lifespan.

2. Versatility Crimped woven mesh can be used in a wide range of applications across multiple industries. From construction to filtration, its flexibility in design and material makes it a popular choice for many use cases.

3. Airflow and Drainage The unique structure of crimped woven mesh allows for excellent airflow and drainage. This makes it ideal for applications where ventilation and moisture control are critical, such as in construction, landscaping, or water treatment.

4. Customization Manufacturers can produce crimped woven mesh in various hole sizes, patterns, and materials, allowing for tailored solutions to meet specific project needs. This customization is particularly beneficial in industries where specialized applications require unique mesh characteristics.

crimped woven mesh

5. Cost-Effectiveness Compared to solid materials, crimped woven mesh provides a budget-friendly solution without compromising strength and functionality. Its lightweight nature can also lead to savings in transport and installation costs.

Applications of Crimped Woven Mesh

1. Construction and Architecture In construction, crimped woven mesh is often used for reinforcing materials, such as in concrete applications or as a safety barrier. Its aesthetic appeal also makes it suitable for architectural applications like decorative screens and facades.

2. Filtration In industrial settings, crimped woven mesh is essential for filtration processes. Its design allows for effective separation of particles from liquids and gases, making it a vital component in water treatment plants and chemical processing.

3. Mining and Quarrying The mining industry benefits from crimped woven mesh for sorting and separating materials, as well as for providing support and safety within tunnels. Its robust nature withstands the harsh conditions often encountered in these environments.

4. Agriculture and Horticulture Crimped woven mesh is also used in agricultural applications, such as fencing, trellises, and supports for climbing plants. Its ability to promote airflow while protecting crops from pests makes it invaluable in farming practices.

5. Industrial and DIY Projects From crafting to heavy-duty industrial tasks, crimped woven mesh finds its way into various DIY projects and industrial applications, showcasing its versatility and practicality.

Conclusion

In summary, crimped woven mesh is a remarkable material that offers numerous benefits across a wide array of applications. Its strength, durability, and versatility make it a go-to solution for industries ranging from construction and mining to agriculture and filtration. As technology advances and more innovative applications emerge, crimped woven mesh is poised to play an even more significant role in meeting the needs of various sectors, making it a material worth considering for any project requiring strength and flexibility.

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025

-

High-Quality Concrete Reinforcement Wire Mesh – Reliable Steel Mesh Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Aluminum Expanded Mesh Leading Manufacturers & Exporters

NewsJul.08,2025

-

High-Quality Perforated Stainless Steel Sheet Manufacturer & Exporter Custom Sizes Available

NewsJul.07,2025

-

High-Quality Galvanized Angle Steel - Reliable Manufacturer, Exporter & Suppliers

NewsJul.07,2025

-

Premium Spiral Tomato Plant Support Stake Leading Manufacturer, Exporter & Supplier

NewsJul.06,2025