-

+86 15030157877

-

sales@galvanizedmetalmesh.com

nov . 09, 2024 10:24 Back to list

Crimped Woven Mesh Production Facilities and Their Innovative Manufacturing Processes

Understanding Crimped Woven Mesh Factories An Overview

Crimped woven mesh has emerged as a vital material in various industrial applications, owing to its unique properties and diverse functionalities. The manufacturing process involves weaving strands of wire into a mesh structure that can be crimped to create a three-dimensional form, enhancing its strength and stability. This article delves into the characteristics, applications, and the significance of crimped woven mesh factories in today's industrial landscape.

Characteristics of Crimped Woven Mesh

Crimped woven mesh is characterized by its unique geometry that arises from the crimping process. The crimping not only gives the mesh its distinctive appearance but also introduces additional tensile strength, allowing it to withstand heavier loads without deformation. The choice of material—commonly stainless steel, carbon steel, or galvanized wire—further influences the mesh’s performance, offering resistance to corrosion and durability under various environmental conditions.

The mesh can be manufactured in various sizes, grid patterns, and crimp types, tailored to meet specific requirements of different industries. This versatility makes it ideal for applications ranging from filtration to construction.

Applications of Crimped Woven Mesh

The applications of crimped woven mesh are extensive and varied. In the construction industry, it is often used for reinforcement purposes in concrete structures. The mesh acts as a barrier to control soil movement and prevent erosion, making it an essential component in retaining walls and foundations.

In the mining and mineral processing sectors, crimped woven mesh serves as a crucial tool for screening and separating materials. Its ability to filter out different sizes of particles ensures efficient processing, making it indispensable in operations involving aggregates, ores, and various granulated substances.

The agriculture sector also benefits from crimped woven mesh. It is utilized in fencing, providing a durable and effective solution for keeping livestock secure while allowing air and light to permeate. Moreover, it can be used in crop protection, shielding plants from pests while maintaining a conducive growing environment.

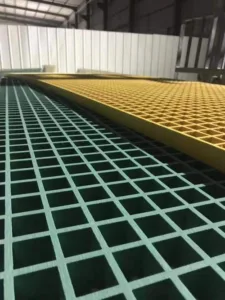

crimped woven mesh factories

In terms of filtration, crimped woven mesh is widely recognized for its effectiveness in different filtration applications, be it for air, liquid, or solid particles. Industries ranging from food and beverage to pharmaceuticals rely on this mesh to ensure that their products meet safety and quality standards.

The Role of Crimped Woven Mesh Factories

Crimped woven mesh factories play a crucial role in the supply chain of various industries by providing high-quality mesh products. These factories are equipped with advanced machinery and skilled labor, allowing for efficient production processes that can meet large-scale demands.

One of the significant advantages of establishing crimped woven mesh factories is the ability to customize products based on client specifications. This customization ensures that customers receive a product that perfectly fits their requirements, which can be a competitive edge in industries where precision is critical.

Moreover, crimped woven mesh manufacturers are often focused on sustainable practices. The recycling of raw materials and minimization of waste during production are becoming increasingly important in the manufacturing industry. Many factories are adopting eco-friendly practices to reduce their carbon footprint while offering products that comply with environmental regulations.

Additionally, the global demand for crimped woven mesh is on the rise as industries continue to expand and modernize. This trend presents a tremendous opportunity for manufacturers to innovate and improve their processes, ensuring that they not only meet current market demands but also anticipate future needs.

Conclusion

In conclusion, crimped woven mesh factories are integral to a wide range of industries, offering products that meet diverse needs while enhancing structural integrity and functionality. The versatility of crimped woven mesh, coupled with advancements in manufacturing technology and a focus on sustainability, positions these factories as vital contributors to modern industrial development. As industries evolve, the importance of crimped woven mesh is set to grow, highlighting the need for continued innovation and adaptation in manufacturing practices. Whether for construction, filtration, agriculture, or other applications, crimped woven mesh will remain a fundamental component in various sectors, driving progress and efficiency forward.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025