-

+86 15030157877

-

sales@galvanizedmetalmesh.com

okt . 07, 2024 03:32 Back to list

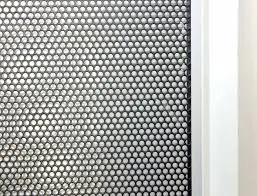

galvanized welded wire mesh factory

Galvanized Welded Wire Mesh Factory An Overview

In the world of construction and fencing, galvanized welded wire mesh has emerged as a vital component due to its versatility, durability, and ease of installation. A galvanized welded wire mesh factory specializes in the production of this essential material, serving various industries and applications from agricultural fencing to concrete reinforcement and architectural designs.

Understanding Galvanized Welded Wire Mesh

Galvanized welded wire mesh is made from high-quality steel wires that are welded together in a grid pattern and then coated with a layer of zinc to prevent rusting. This galvanization process enhances the wire's resistance to corrosion, ensuring a longer lifespan even in harsh environmental conditions. The mesh is available in various sizes, wire gauges, and mesh patterns, making it suitable for applications ranging from animal enclosures to building security.

Manufacturing Process

The production of galvanized welded wire mesh involves several steps. It begins with selecting high-grade raw materials, typically steel wires, which are then cut, cleaned, and bent into the desired shape. The wires are welded at their intersections to create a strong grid structure. After welding, the mesh is subjected to a galvanization process, where it is dipped in molten zinc or coated via electro-galvanizing methods. This zinc layer not only protects the steel but also gives the mesh a shiny, attractive finish.

Quality control is paramount in a galvanized welded wire mesh factory. Each batch of wire mesh undergoes rigorous testing to ensure it meets industry standards for strength, durability, and corrosion resistance. Factories often employ advanced technologies and machinery to streamline production while maintaining high-quality output.

Applications of Galvanized Welded Wire Mesh

galvanized welded wire mesh factory

Galvanized welded wire mesh finds applications in a myriad of sectors. In construction, it is commonly used as reinforcement in concrete slabs, walls, and foundations, providing additional tensile strength. In agricultural settings, it serves as fencing for livestock, protection for crops, and enclosures for poultry. It is also a popular choice for security fencing in commercial and industrial areas due to its formidable strength and visibility deterrent.

Another interesting application is in the DIY and home improvement sector where galvanized welded wire mesh is used in crafting projects, garden fencing, and even as frameworks for growing climbing plants. Its versatility ensures that it is a staple in many hardware stores, catering to both professionals and amateurs alike.

Sustainability and Innovation

Modern galvanized welded wire mesh factories are increasingly adopting sustainable practices. This includes utilizing recycled materials in their production processes and implementing energy-efficient machinery. Moreover, advancements in technology have led to the development of stronger and lighter mesh products, meeting the evolving demands of customers.

As the market continues to grow, galvanized welded wire mesh factories are poised for innovation. From customized mesh solutions to smart manufacturing processes, the future looks bright for both manufacturers and consumers.

Conclusion

In summary, galvanized welded wire mesh factories play a crucial role in various industries by providing a reliable, durable, and cost-effective solution for numerous applications. With ongoing advancements in technology and a commitment to sustainability, these factories are not only meeting current demands but also paving the way for future innovations in mesh production.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025