-

+86 15030157877

-

sales@galvanizedmetalmesh.com

aug . 10, 2025 02:20 Back to list

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

The Imperative of Robust Storage Solutions in Modern Industry: An Overview of Storage Cage Technology

In the intricate landscape of contemporary industrial operations, characterized by escalating demands for efficiency, safety, and optimal space utilization, the role of advanced material handling and storage solutions has transcended mere utility to become a strategic imperative. Businesses across diverse sectors, from automotive manufacturing and logistics distribution centers to highly specialized pharmaceutical production and robust aerospace engineering, are continually seeking methodologies to streamline their inventory management, protect valuable assets, and ensure seamless operational workflows. It is within this critical context that the Storage Cage emerges not just as a piece of equipment but as a foundational element of a highly organized, safe, and productive industrial ecosystem. The evolution of these essential units from simple containment devices to sophisticated, engineered solutions reflects a deep understanding of industry trends, which invariably point towards greater automation, modularity, and environmental sustainability. For instance, the escalating cost of industrial real estate, particularly in urbanized manufacturing hubs, necessitates storage solutions that maximize vertical space and allow for rapid reconfiguration, making stackable and collapsible designs paramount. Furthermore, the global shift towards lean manufacturing principles and just-in-time (JIT) inventory systems mandates that stored goods are readily accessible, identifiable, and protected from damage or loss, thereby reducing lead times and minimizing operational bottlenecks. The increasing stringency of workplace safety regulations, driven by international bodies like OSHA and regional equivalents, underscores the need for storage solutions that prevent accidents related to unstable stacking or falling objects, demanding robust construction and secure locking mechanisms. Beyond these operational efficiencies, the choice of material and surface treatment for a Storage Cage directly impacts its longevity, particularly in challenging environments such as cold storage, humid warehouses, or outdoor applications, where corrosion resistance is paramount. This necessitates a detailed exploration of galvanized finishes and other protective coatings that extend the operational life cycle and reduce long-term capital expenditure. The integration of advanced features such as forklift pockets, casters for mobility, and specialized dividers transforms a standard cage into a versatile tool adaptable to a myriad of logistics challenges, from temporary staging of work-in-progress (WIP) materials on a factory floor to secure storage of high-value components in a distribution center. Understanding these multifaceted requirements is crucial for B2B decision-makers and technical personnel who are tasked with optimizing their material flow and asset protection strategies, ensuring that their investment in Storage Cage technology yields maximum return in terms of efficiency, safety, and durability. This introductory discussion lays the groundwork for a comprehensive examination of Storage Cage technology, delving into its design principles, manufacturing intricacies, diverse applications, and the tangible benefits it confers upon modern industrial operations.

Engineering the Foundation: The Meticulous Manufacturing Process of a High-Performance Storage Cage

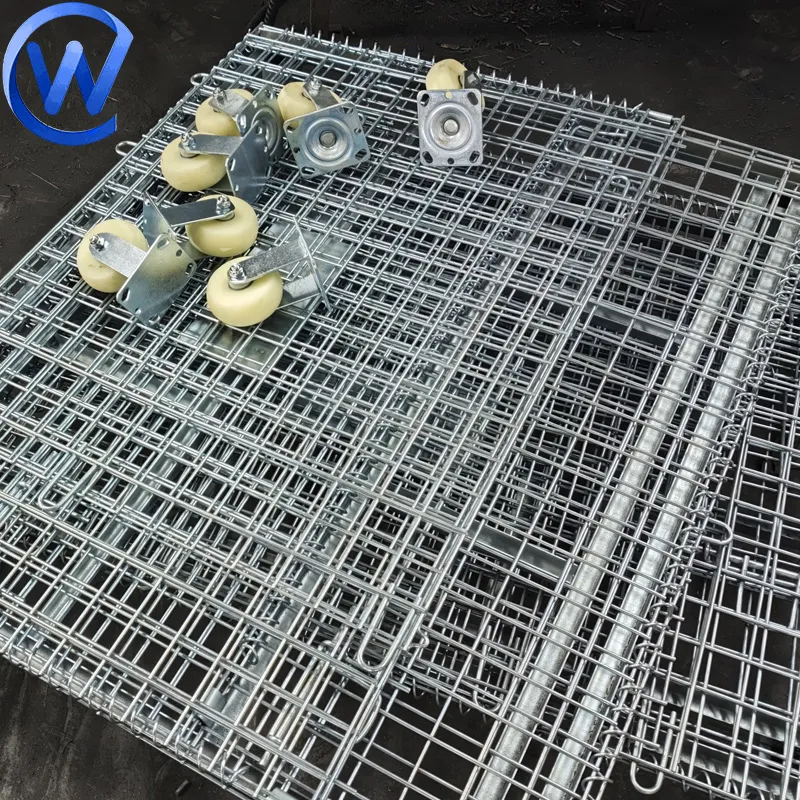

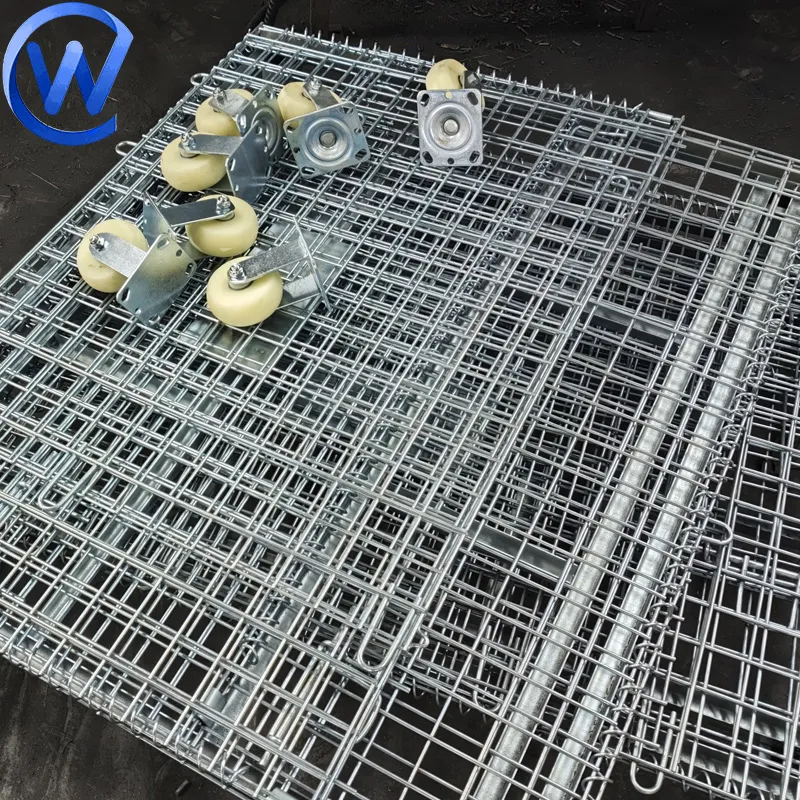

The production of a durable and reliable Storage Cage is a sophisticated industrial process that relies heavily on precision engineering, robust material selection, and rigorous quality control, distinguishing professional-grade solutions from lesser alternatives. The journey begins with the selection of high-grade steel, typically Q235 or Q345 mild steel, chosen for its excellent strength-to-weight ratio and weldability, forming the skeletal integrity of the cage. Unlike components requiring casting or forging for complex geometries, Storage Cage manufacturing primarily involves advanced metal fabrication techniques. The initial phase is material preparation, where steel rods or wire mesh are precisely cut to size using automated CNC cutting machines, ensuring dimensional accuracy and minimizing material waste. Following this, the components undergo forming processes; for instance, the wire mesh panels are often straightened and cut, while structural frames are bent or shaped using hydraulic presses or specialized bending machines to achieve the desired profiles for stability and stackability. The critical phase of assembly involves high-precision welding, predominantly resistance welding for mesh panels and MIG/TIG welding for structural frames and uprights. This ensures robust joints capable of withstanding significant loads and repeated handling stresses. Post-welding, each component undergoes deburring and cleaning to remove any sharp edges or contaminants, preparing the surface for the protective coating. The primary protective process for industrial Storage Cage units is hot-dip galvanization, which involves immersing the fabricated steel structure into a bath of molten zinc at temperatures around 450°C (842°F). This metallurgical bonding process creates a highly durable, corrosion-resistant coating that offers superior protection compared to painted or electroplated finishes, acting as a sacrificial barrier against rust and abrasion. This process adheres to stringent international standards such as ASTM A123/A123M for hot-dip galvanized coatings on iron and steel products, ensuring uniformity and specified minimum coating thickness, which directly correlates to the product's longevity. Other finishing options, depending on specific environmental requirements, might include powder coating over galvanized surfaces for enhanced aesthetics or additional chemical resistance. Throughout the entire manufacturing chain, adherence to strict quality assurance protocols is paramount. This includes initial material inspection, in-process dimensional checks after cutting and forming, visual inspection of welds, and critical post-galvanization checks for coating uniformity and adhesion. Load testing is often performed on prototypes and batch samples to verify the cage's static and dynamic load capacities, ensuring compliance with design specifications and safety standards like ISO 9001 for quality management systems and ANSI MH30.1 for industrial steel storage racks, though the latter is more specific to racking, the principles of structural integrity and load bearing are transferable. The expected service life of a well-manufactured, hot-dip galvanized Storage Cage can easily exceed 15-20 years even in challenging industrial environments, significantly outperforming ungalvanized or painted alternatives, which may show signs of corrosion within 3-5 years. Applicable industries that benefit immensely from this robust manufacturing include logistics and warehousing, where cages are constantly moved and exposed to varying conditions; automotive, for parts storage and work-in-progress; manufacturing, for component staging; and even agricultural sectors for bulk produce handling. The inherent durability and corrosion resistance imparted by proper manufacturing techniques, especially galvanization, translate directly into reduced maintenance costs and an enhanced operational lifespan, thereby significantly reducing the total cost of ownership for businesses, emphasizing the long-term value over initial purchase price. This meticulous process ensures that each Storage Cage is not just a container111 but a resilient, long-term asset capable of enduring the rigors of heavy industrial use while maintaining structural integrity and product protection.

Technical Specifications and Performance Metrics of Advanced Storage Cage Designs

Understanding the detailed technical specifications and performance metrics of a Storage Cage is critical for procurement managers and engineers to ensure that the chosen solution precisely matches the operational demands and safety requirements of their facility. Beyond the basic dimensions, key parameters define a cage's utility, durability, and suitability for specific applications. Load capacity is arguably the most crucial metric, typically categorized into static load capacity and dynamic load capacity. Static load refers to the maximum weight the cage can safely hold when stationary and stacked, often ranging from 1,000 kg to 2,500 kg (2,200 lbs to 5,500 lbs) for heavy-duty industrial models, while dynamic load pertains to the weight it can withstand during movement, particularly when lifted by forklifts or pallet jacks, which is usually a slightly lower figure due to forces incurred during transit. Stackability is another vital parameter, defining how many loaded cages can be safely stacked on top of each other without compromising structural integrity or contents, commonly ranging from 3 to 5 layers high, depending on the cage design and material thickness. Mesh size, typically varying from 50mm x 50mm (2"x2") to 100mm x 100mm (4"x4"), influences the visibility of contents, airflow, and the security against small items falling through, with smaller mesh sizes providing greater security for smaller parts. The material gauge, referring to the thickness of the wire mesh and structural tubing, directly impacts the cage's overall strength and resistance to deformation, with heavier gauges indicating greater robustness. Surface finish, predominantly hot-dip galvanization, as discussed, is critical for corrosion resistance, offering decades of protection in harsh environments. Other features like half-drop gates, which allow easy access to contents even when stacked, and forklift pockets, integrated channels for secure forklift handling, significantly enhance operational efficiency. Casters, available in various materials like nylon, polyurethane, or rubber, dictate mobility and suitability for different floor types, with lockable casters providing stability when stationary. The overall dimensions (length, width, height) must align with available storage space, pallet sizes, and transport vehicle dimensions, ensuring seamless integration into existing logistics chains. For instance, a common industrial size might be 1200mm x 1000mm x 890mm (48" x 40" x 35"), designed to accommodate standard pallets. The design also often incorporates features for collapsibility, allowing cages to be folded flat when empty to save return freight costs and storage space, reducing their volume by up to 80%. When evaluating solutions, a comparative analysis against established industry benchmarks is paramount. For example, a cage designed to meet ISO 9001 standards guarantees a consistent level of quality management in its production, while adherence to specific material standards (e.g., ASTM A513 for welded mechanical tubing) ensures the quality of raw materials. Understanding these nuanced technical aspects allows businesses to make informed decisions that optimize their investment, ensuring not only immediate operational benefits but also long-term reliability and safety.

Typical Storage Cage Specifications Table

| Parameter | Typical Range/Value | Unit of Measure |

|---|---|---|

| External Dimensions (L x W x H) | 1200 x 1000 x 890 to 1000 x 800 x 840 | mm |

| Internal Dimensions (L x W x H) | 1140 x 940 x 750 to 950 x 750 x 700 | mm |

| Static Load Capacity | 1500 - 2500 | kg |

| Dynamic Load Capacity | 800 - 1500 | kg |

| Stacking Height (Loaded) | 3 - 5 | layers |

| Mesh Size (LxW) | 50 x 50 to 100 x 100 | mm |

| Wire Diameter | 5.0 - 6.5 | mm |

| Base Type | Forklift Pocket / Pallet Jack Entry | N/A |

| Surface Finish | Hot-dip Galvanized | N/A |

| Material | Q235/Q345 Steel | N/A |

| Features | Collapsible, Stackable, Half-drop Gate | N/A |

Strategic Application and Operational Advantages of Modern Storage Cage Solutions

The deployment of an advanced Storage Cage is not merely about containment but represents a strategic enhancement to operational efficiency, safety, and inventory management across a multitude of industrial environments. Its versatility allows for seamless integration into diverse workflows, from high-volume logistics and distribution centers to intricate manufacturing assembly lines and robust recycling facilities. In the automotive sector, for example, these cages are indispensable for organizing and protecting components during assembly, warehousing spare parts, or facilitating efficient transfer of work-in-progress (WIP) between different production stages. Their open mesh design allows for quick visual inventory checks, reducing the time spent locating specific parts and minimizing errors, a critical factor in rapid-paced manufacturing. For general logistics and warehousing, Storage Cage units optimize vertical space through their stackability, significantly increasing storage density within existing footprints, which directly translates to reduced real estate costs and improved facility throughput. The robust construction and secure locking mechanisms safeguard valuable or sensitive inventory from damage, theft, or environmental exposure, particularly when paired with a hot-dip galvanized finish that offers unparalleled corrosion resistance for both indoor and outdoor applications. This anti-corrosion property is particularly advantageous in sectors like agriculture for storing produce or in construction for holding tools and materials on site, where exposure to elements is common. Furthermore, the standardized dimensions of many industrial Storage Cage models ensure compatibility with standard material handling equipment such as forklifts, pallet jacks, and automated guided vehicles (AGVs), facilitating swift and safe movement of goods within the facility and during transportation. The inherent durability reduces the frequency of equipment replacement and maintenance, contributing to long-term cost savings. Beyond these direct benefits, the environmental advantages, though less direct in terms of "energy saving" for a passive storage unit, are notable: by optimizing storage density, facilities can potentially reduce the need for expansion, thereby conserving land and construction resources. The longevity afforded by quality materials and galvanization minimizes waste from premature degradation, promoting a more sustainable operational model. Collapsible designs further reduce the carbon footprint associated with return logistics, as empty cages occupy minimal space during transit. For instance, a collapsed cage can reduce its volume by up to 80%, allowing for up to five times more empty cages to be transported per truckload compared to rigid container111s, drastically cutting freight costs and fuel consumption. In summary, the strategic adoption of high-quality Storage Cage solutions empowers businesses to enhance their operational agility, safeguard assets, optimize spatial utilization, and achieve substantial cost efficiencies, solidifying their position as a cornerstone of modern industrial infrastructure. This adaptability and robust performance ensure that these cages are not just passive storage units but active enablers of highly efficient and secure material flow within the supply chain, demonstrating their multifaceted value beyond simple material containment.

Elevating Performance: Key Advantages and Value Proposition of Premium Storage Cage Designs

The selection of a premium Storage Cage offers a significant competitive advantage to businesses, extending far beyond the basic function of holding goods. These advanced designs incorporate features and material specifications that directly translate into tangible benefits, impacting operational efficiency, safety, and long-term cost savings. One of the foremost advantages is their exceptional durability, primarily attributed to high-quality steel construction (e.g., Q235 or Q345 grade) combined with a superior hot-dip galvanized finish. This robust combination ensures unparalleled resistance to corrosion, rust, and physical wear, even in challenging environments like cold storage facilities, outdoor yards, or areas exposed to chemicals, drastically extending the service life of the cage to 15-20 years or more. This longevity minimizes the need for frequent replacements, leading to substantial reductions in capital expenditure over time. Another critical advantage is the optimization of space. Premium Storage Cage units are meticulously engineered for high stackability, often allowing for 4-high or even 5-high stacking when loaded, safely leveraging vertical warehouse space that would otherwise be underutilized. This dramatically increases storage density, potentially reducing the need for costly facility expansions. Furthermore, many high-end models are designed to be collapsible, meaning they can be folded flat when empty, reducing their volume by up to 80%. This feature is invaluable for optimizing return logistics, allowing more empty cages to be transported on a single truckload, leading to significant savings in freight costs and reduced carbon emissions. Enhanced operational efficiency is another cornerstone benefit. Features like half-drop gates provide easy access to contents even when cages are stacked, eliminating the need to unstack multiple units just to retrieve an item from a lower cage. Integrated forklift pockets and heavy-duty casters ensure smooth, secure, and rapid movement of goods within the facility, minimizing handling time and reducing the risk of product damage or worker injury. The open mesh design, a hallmark of these cages, allows for quick visual inventory checks, improving accuracy and reducing errors in picking and packing processes. From a safety perspective, the robust construction and secure latching mechanisms prevent accidental spills or collapses, protecting both personnel and valuable inventory. Compliance with international safety standards and load ratings provides an additional layer of assurance. While a Storage Cage doesn't directly "save energy" in its operation, its contribution to operational fluidity and space optimization can indirectly lead to energy efficiencies by enabling more streamlined processes and potentially reducing the need for larger, energy-intensive storage facilities. For instance, better organization facilitated by cages can reduce lighting and heating requirements in aisles by shortening retrieval times. The reduction in damaged goods due to secure storage also contributes to sustainability by minimizing waste. Ultimately, the investment in a premium Storage Cage translates into a lower total cost of ownership, improved workflow, enhanced safety, and a more sustainable operational footprint, making it a pivotal asset for any forward-thinking industrial enterprise committed to long-term efficiency and profitability.

Comparative Analysis: Key Features of Different Storage Cage Types

| Feature/Type | Standard Collapsible Storage Cage | Heavy-Duty Storage Cage | Security Mesh Storage Cage (Fine Mesh) |

|---|---|---|---|

| Load Capacity (Static) | 1500 kg | 2500 kg+ | 1000 - 2000 kg |

| Wire Diameter | 5.0 mm - 6.0 mm | 6.0 mm - 8.0 mm | 4.0 mm - 5.0 mm |

| Mesh Size | 50x50 mm to 100x100 mm | 50x50 mm to 100x100 mm | 25x50 mm to 50x50 mm (finer) |

| Collapsibility | Yes (standard) | Typically Yes, or rigid for maximum load | Yes, often with integrated locking |

| Access Gate | Half-drop gate (common) | Full or Half-drop, reinforced | Lockable, secure door |

| Typical Use Case | General warehousing, manufacturing, logistics | Heavy machinery parts, industrial components, bulk goods | High-value items, small parts, tools, electronics |

| Surface Finish | Hot-dip Galvanized | Hot-dip Galvanized (heavier coating) | Hot-dip Galvanized, sometimes powder-coated |

Tailored Excellence: Custom Storage Cage Solutions and Manufacturer Selection

While standard Storage Cage models serve a broad range of industrial applications, a truly optimized material handling strategy often necessitates custom solutions that perfectly align with unique operational requirements, spatial constraints, and specific product characteristics. A reputable manufacturer of Storage Cage units distinguishes itself not only through its catalog of standard products but, crucially, through its capacity for bespoke design and engineering. This might involve altering dimensions to fit non-standard pallets or existing racking systems, integrating specialized internal dividers or shelves for organizing diverse component sizes, or incorporating unique security features like reinforced doors and advanced locking mechanisms for high-value items. Customization can also extend to the base design, such as adding heavy-duty casters for enhanced mobility within a facility or designing specialized feet for precise integration with automated conveyor systems. Furthermore, specialized surface treatments beyond standard hot-dip galvanization, such as electro-polished stainless steel for pharmaceutical or food-grade applications, or specific color powder coatings for brand identification or departmental segregation, represent areas of customization. When selecting a manufacturing partner, several critical factors must be rigorously assessed to ensure a long-term, mutually beneficial relationship and a high-quality product. Foremost is the manufacturer's demonstrated expertise and experience in the field of metal fabrication and material handling solutions. A strong track record, evidenced by successful application cases and positive client testimonials from diverse industries, provides reassurance of their capabilities. Certifications such as ISO 9001 for quality management systems are non-negotiable, indicating a commitment to consistent quality and continuous improvement in their production processes. The availability of in-house design and engineering teams is also vital, as it ensures that custom requirements can be translated into practical, cost-effective, and structurally sound designs. Furthermore, a manufacturer's commitment to after-sales support, including warranty provisions, spare parts availability, and technical assistance, underscores their reliability and dedication to customer satisfaction. Evaluating their production capacity and lead times is equally important to ensure that large orders or urgent requirements can be met without compromising project schedules. Lastly, a comprehensive understanding of their manufacturing processes, from raw material sourcing and welding techniques to quality control and finishing, provides insight into the inherent quality and longevity of their Storage Cage products. For instance, a manufacturer that openly details its galvanization process and adherence to standards like ASTM A123 demonstrates a higher level of transparency and quality commitment. Engaging in a thorough vendor assessment that includes site visits, reference checks, and a detailed review of their design capabilities will empower B2B decision-makers to choose a partner capable of delivering not just a product, but a tailored solution that enhances their operational efficiency and provides long-term value, ultimately ensuring that their investment in Storage Cage technology is both sound and strategic, aligning perfectly with their evolving business needs and contributing to overall supply chain resilience and profitability.

Real-World Impact: Case Studies and Client Success with Advanced Storage Cage Deployments

The theoretical advantages of Storage Cage solutions are best illuminated through real-world application cases, demonstrating their transformative impact on operational efficiency, safety, and cost reduction across diverse industries. One compelling example comes from a large-scale automotive manufacturing plant grappling with a persistent challenge: inefficient storage and transfer of engine components between different assembly lines. Prior to implementing a tailored Storage Cage system, parts were stored on traditional pallets, leading to significant material damage during transit, difficulty in inventory tracking, and substantial wasted vertical space. By deploying custom-sized, stackable, and collapsible Storage Cage units with specialized internal dividers, the plant achieved remarkable improvements. Damage rates for engine components dropped by over 70% in the first six months, leading to a projected annual saving of $500,000 in material replacement costs. The ability to stack cages four high increased floor space utilization by 40%, deferring the need for warehouse expansion and saving an estimated $2 million in potential construction costs. Furthermore, the visual accessibility of parts within the mesh cages reduced picking times by an average of 15%, directly contributing to a more streamlined production flow. Another notable success story involves a major third-party logistics (3PL) provider managing a complex array of consumer goods. Their primary challenge was optimizing their vast warehouse space and ensuring rapid order fulfillment. The implementation of high-density, collapsible Storage Cage solutions allowed them to categorize and store diverse product types more effectively. During peak seasons, the stackable nature of the cages enabled them to surge their storage capacity without external warehousing, while the collapsible feature significantly reduced costs associated with empty container111 returns – reducing freight volume by 75% on backhauls. This resulted in an estimated 18% reduction in annual transportation costs and a 10% improvement in inventory turnover rates due to enhanced accessibility and organization. In the petrochemical industry, where materials handling often involves components exposed to corrosive elements or requiring secure containment, specialized hot-dip galvanized Storage Cage units have proven invaluable. One refinery reported that by using these corrosion-resistant cages for storing critical valves and pipes outdoors, they eliminated the need for costly indoor storage space and significantly extended the lifespan of these valuable assets, which previously suffered from premature degradation due to environmental exposure. This decision not only saved on warehousing expenses but also reduced capital expenditure on replacement parts by an average of $250,000 annually. These varied application scenarios underscore that the true value of a Storage Cage lies in its strategic integration into a holistic material handling system. The tangible benefits – from enhanced asset protection and optimized space utilization to significant reductions in operational costs and improvements in workflow efficiency – collectively demonstrate why these engineered solutions are considered indispensable assets for modern industrial enterprises striving for operational excellence and long-term sustainability.

Ensuring Trust and Longevity: Warranty, Support, and Frequently Asked Questions for Storage Cage Solutions

Beyond the technical specifications and operational benefits, the true measure of a reliable supplier of Storage Cage products lies in their commitment to customer trustworthiness, demonstrated through comprehensive after-sales support, transparent warranty policies, and accessible client services. A robust warranty program is a cornerstone of this commitment. Reputable manufacturers typically offer a warranty period of 1 to 5 years against manufacturing defects and material failures under normal usage conditions. This commitment reflects their confidence in the quality of their hot-dip galvanized products and provides buyers with essential peace of mind, knowing that their investment is protected. Clear terms and conditions for warranty claims, including guidelines for proper use and maintenance, are usually provided to ensure mutual understanding. Alongside warranty, a transparent delivery schedule and efficient logistics are paramount for B2B buyers. Manufacturers should be able to provide accurate lead times, ranging from typically 2-4 weeks for standard products to 6-10 weeks for highly customized solutions, depending on volume and complexity. Reliable suppliers often utilize advanced logistics planning to ensure on-time delivery, minimizing disruptions to client operations. Post-purchase, readily available customer support is crucial. This includes technical assistance for installation queries, guidance on optimal loading and stacking practices, and troubleshooting common issues. Access to a dedicated support team via phone, email, or online portals ensures that any operational concerns can be addressed swiftly, minimizing downtime. Furthermore, the provision of spare parts, such as replacement hinges, latches, or damaged mesh panels, ensures the longevity and continued utility of the Storage Cage units, extending their operational life beyond the initial warranty period. This proactive approach to customer service underscores a manufacturer's dedication to long-term client relationships rather than mere transactional sales. To further enhance trustworthiness and address common client queries upfront, a comprehensive Frequently Asked Questions (FAQ) module is invaluable. Such a module should cover practical aspects from product selection to maintenance. For example, common questions often include: "What is the typical lifespan of a hot-dip galvanized Storage Cage?" (Answer: 15-20 years or more, owing to superior corrosion resistance compared to paint); "Are your cages compatible with standard forklifts and pallet jacks?" (Answer: Yes, designed to industry-standard pallet dimensions and forklift pocket spacing); "How does a collapsible design benefit my operation?" (Answer: Reduces return freight costs and empty storage space by up to 80%); "Can these cages be used outdoors?" (Answer: Yes, the hot-dip galvanized finish provides excellent weather resistance, making them suitable for outdoor storage); "What is the difference between static and dynamic load capacity?" (Answer: Static is for stationary, stacked weight; dynamic is for weight during movement/lifting); and "Do you offer custom sizes or features?" (Answer: Yes, custom engineering is available to meet specific dimensional or functional requirements). By proactively addressing these and other potential questions, manufacturers build confidence and demonstrate their expert authority and commitment to transparent, supportive service, fostering stronger partnerships with their B2B clientele. This holistic approach to customer care ensures that the acquisition of Storage Cage solutions is not just a purchase, but an investment supported by ongoing reliability and dedicated assistance.

Frequently Asked Questions (FAQ) about Storage Cage Units

-

Q: What makes hot-dip galvanization superior for Storage Cage durability?

A: Hot-dip galvanization involves immersing the steel Storage Cage into molten zinc, creating a metallurgical bond that provides a thicker, more uniform, and highly adherent coating compared to electroplating or painting. This process results in a sacrificial layer that protects the steel even if scratched, significantly enhancing corrosion resistance, extending the cage's lifespan to 15-20 years or more, and reducing maintenance costs, making it ideal for harsh industrial environments, including outdoor or humid conditions, unlike painted surfaces which can chip and allow rust to form rapidly. This adherence to industry standards like ASTM A123 ensures long-term asset protection and a superior return on investment.

-

Q: Can Storage Cage units be customized for specific industry needs?

A: Absolutely. While standard dimensions cater to common requirements, leading manufacturers specialize in providing bespoke Storage Cage solutions. Customizations can include altering dimensions (e.g., length, width, height) to perfectly fit unique spaces or accommodate non-standard items, integrating specialized internal partitions or shelves for intricate component organization, adding specific caster types for enhanced mobility, or incorporating advanced security features like heavier gauge wire mesh or multi-point locking mechanisms for high-value goods. These tailored designs ensure seamless integration into existing material handling systems and optimize operational workflows for specialized applications, such as in aerospace component storage or sensitive pharmaceutical logistics, reflecting a deeper understanding of specific client pain points and operational nuances.

-

Q: How do collapsible Storage Cage designs contribute to cost savings?

A: Collapsible Storage Cage designs offer significant cost savings primarily through optimizing space utilization during return logistics and empty storage. When not in use, these cages can be folded down to a fraction of their assembled volume, often reducing it by up to 80%. This reduction means that more empty cages can be transported per truckload, drastically cutting down on freight costs for return journeys. Furthermore, the minimized footprint of collapsed cages saves valuable warehouse space that would otherwise be consumed by rigid empty container111s, allowing facilities to maximize their storage capacity for active inventory or other operational needs. This feature is particularly beneficial for businesses with cyclical inventory flows or extensive inter-facility transfers, offering a compelling return on investment by reducing both transportation and warehousing overheads, ultimately enhancing the overall efficiency and profitability of the supply chain operations.

The Future of Industrial Storage: Evolving Trends and the Enduring Role of the Storage Cage

As global supply chains become increasingly complex and dynamic, the landscape of industrial storage is undergoing significant transformation, driven by technological advancements, shifting consumer demands, and a heightened focus on sustainability. In this evolving environment, the Storage Cage is not merely retaining its relevance but is actively adapting and expanding its role as a fundamental component of efficient and intelligent warehousing and logistics systems. One key trend is the accelerating adoption of automation within warehouses and distribution centers, ranging from robotic picking systems to automated storage and retrieval systems (AS/RS) and automated guided vehicles (AGVs). For the Storage Cage to seamlessly integrate into these highly automated environments, future designs will increasingly feature precision-engineered bases compatible with robotic gripping mechanisms, standardized RFID tag or barcode integration for enhanced inventory tracking, and consistent dimensional tolerances to ensure smooth movement through automated conveyors. The demand for greater data visibility and real-time inventory insights will drive innovations such as smart cages equipped with sensors for temperature, humidity, or even GPS tracking for high-value items in transit, enabling predictive maintenance and optimized stock rotation. Another significant trend is the push towards greater modularity and flexibility in storage solutions. As businesses navigate fluctuating market demands and seasonal peaks, the ability to rapidly reconfigure warehouse layouts and adapt storage capacity becomes paramount. The inherent stackability and collapsibility of the Storage Cage position it as an ideal modular unit, capable of forming dynamic storage structures that can be quickly deployed or dismantled, reducing reliance on fixed, expensive infrastructure. This flexibility also supports the growth of micro-fulfillment centers and urban logistics hubs, where space is at a premium and rapid reconfiguration is essential. Furthermore, sustainability is no longer a peripheral concern but a core strategic pillar for many enterprises. The long lifespan of hot-dip galvanized Storage Cage units, minimizing waste and resource consumption from frequent replacements, aligns perfectly with circular economy principles. Future developments may include the use of recycled steel and even more environmentally friendly galvanization processes. The indirect energy savings achieved through optimized space utilization and reduced transport volumes, as enabled by collapsible designs, will continue to grow in importance. The material handling industry is also witnessing an increased emphasis on safety, with continuous improvements in ergonomic design and enhanced safety features for Storage Cage products, such as improved locking mechanisms and more intuitive handling features, to reduce workplace injuries. In conclusion, while its fundamental purpose remains consistent, the Storage Cage is poised for continuous evolution, integrating smart technologies, enhancing its modular capabilities, and reinforcing its role as an environmentally conscious, highly adaptable, and indispensable asset in the complex, technology-driven supply chains of tomorrow. Its enduring value lies in its proven reliability and its capacity to adapt to the evolving demands for efficiency, automation, and sustainability in the global industrial landscape.

Industry Insights and Further Reading

For those seeking deeper insights into the material handling industry and the specific role of storage solutions, the following authoritative sources and publications offer comprehensive data, trend analyses, and research. These resources are invaluable for B2B decision-makers and technical personnel aiming to stay abreast of best practices and emerging technologies in warehousing and logistics.

-

Modern Materials Handling: A leading industry publication offering extensive coverage of material handling equipment, systems, and technologies, including detailed analyses of storage solutions. Their articles often feature case studies, expert opinions, and market forecasts that are highly relevant to the strategic deployment of assets like the Storage Cage.

https://www.mmh.com/ -

Warehousing & Logistics International (WLI): This journal provides global perspectives on warehouse operations, supply chain management, and logistics technology. It frequently publishes technical papers and industry reports that delve into topics such as space optimization, automated warehousing, and the performance metrics of various storage equipment, including mesh cages.

https://www.warehousing-logistics.com/ -

Material Handling Industry (MHI): MHI is a leading trade association that represents the U.S. material handling, logistics, and supply chain industry. Their website offers white papers, industry reports, and educational resources on a wide array of topics, including safety standards, equipment specifications, and technological innovations impacting storage solutions.

https://www.mhi.org/ -

Journal of Logistics, Informatics and Service Science (JLISS): For a more academic and research-oriented perspective, JLISS publishes peer-reviewed articles on logistics, supply chain management, and the application of information technology in these fields. Research on optimization algorithms for warehouse layout or the impact of specific equipment on supply chain efficiency can be highly valuable.

https://ejlss.aserspublishing.eu/ -

ASTM International: The American Society for Testing and Materials (ASTM) provides global standards for a vast array of materials and products. Specifically, standards like ASTM A123/A123M for hot-dip galvanization are crucial references for understanding the quality and longevity of surface finishes on metal products such as Storage Cage units. Consulting these standards ensures a deep understanding of material integrity.

https://www.astm.org/

These resources collectively provide a robust framework for understanding the technical nuances, market dynamics, and strategic importance of high-quality Storage Cage solutions within the broader context of modern industrial logistics. Engaging with these authoritative sources can significantly enhance decision-making processes for businesses looking to optimize their material handling and storage infrastructure, ensuring investments are both informed and future-proof.

This is the last article

-

Heavy-Duty Stackable Storage Cages – Secure & Space-Saving

NewsAug.10,2025

-

Stainless Steel Angle Factories | Top Suppliers & Manufacturers

NewsAug.09,2025

-

Artificial Grass Fence: Privacy, Beauty & Low Maintenance

NewsAug.08,2025

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025