-

+86 15030157877

-

sales@galvanizedmetalmesh.com

mrt . 03, 2025 13:49 Back to list

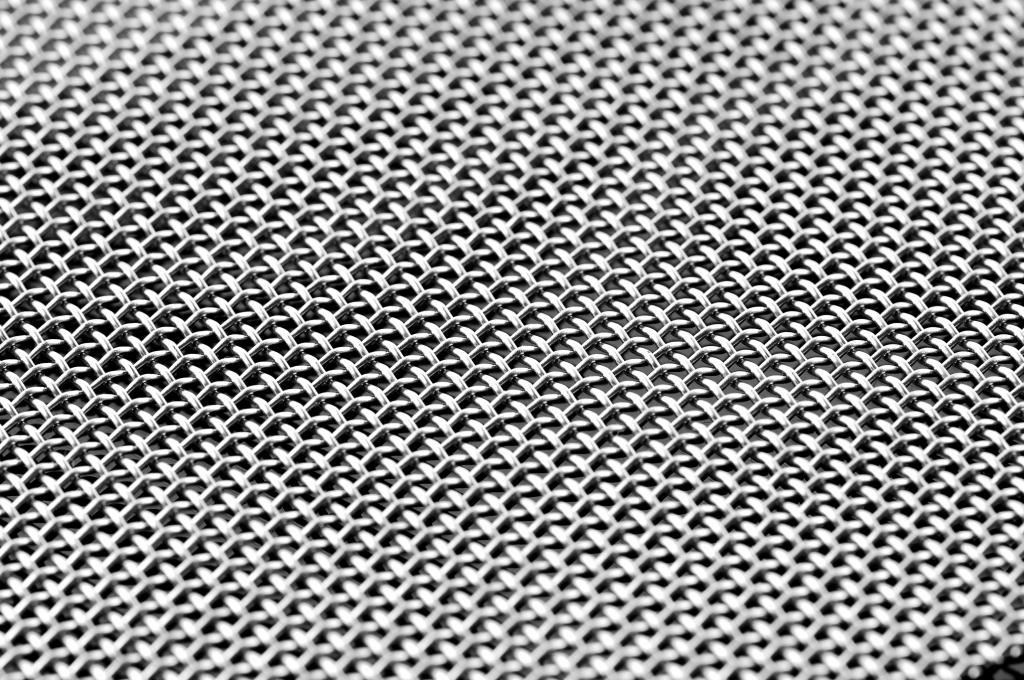

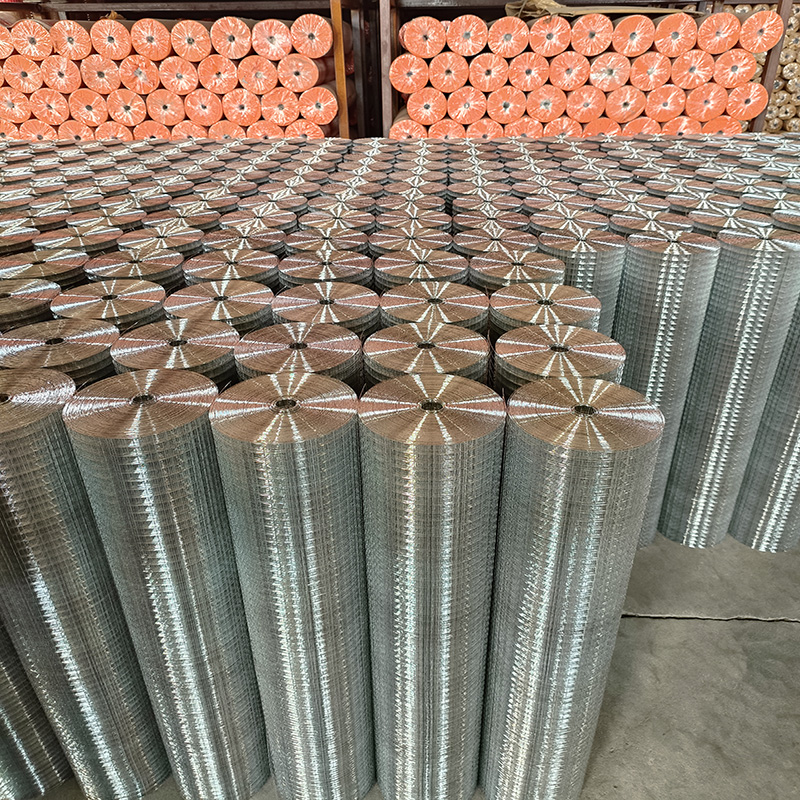

high quality grating steel

High quality grating steel plays a pivotal role in various industrial applications, providing robust solutions for flooring, walkways, and safety enclosures across industries. This versatile material, known for its unmatched strength and durability, is engineered to meet the demanding conditions that are prevalent in today's manufacturing and construction sectors.

Beyond its functional benefits, the economic advantages of opting for high quality grating steel cannot be overstated. While providing long-lasting solutions, it offers substantial cost savings on repairs and replacements. Its resilience in diverse climates and environments ensures that once installed, these components continue to perform optimally with minimal intervention, driving down the total cost of ownership for businesses. Additionally, trustworthy manufacturers and suppliers in this field invest in rigorous quality control measures, providing assurance to clients through various certification and testing procedures. This commitment to quality reflects on each piece of grating steel produced, ensuring clients receive products that align perfectly with industry standards and project specifications. Through ongoing innovation and refinement in manufacturing processes, high quality grating steel continually evolves to meet the ever-changing demands of modern infrastructure projects. As such, investing in this material aligns with forward-thinking strategies in construction and industrial applications, where resilience and high performance are primary considerations. Ultimately, choosing high quality grating steel signifies a commitment to excellence in both safety and functionality, a testament to its indispensable role in the current industrial landscape. Its ability to adapt to various applications while maintaining robust performance is why seasoned professionals in the industry continue to rely on it as a critical component in their design and construction efforts, underscoring its importance well into the future.

Beyond its functional benefits, the economic advantages of opting for high quality grating steel cannot be overstated. While providing long-lasting solutions, it offers substantial cost savings on repairs and replacements. Its resilience in diverse climates and environments ensures that once installed, these components continue to perform optimally with minimal intervention, driving down the total cost of ownership for businesses. Additionally, trustworthy manufacturers and suppliers in this field invest in rigorous quality control measures, providing assurance to clients through various certification and testing procedures. This commitment to quality reflects on each piece of grating steel produced, ensuring clients receive products that align perfectly with industry standards and project specifications. Through ongoing innovation and refinement in manufacturing processes, high quality grating steel continually evolves to meet the ever-changing demands of modern infrastructure projects. As such, investing in this material aligns with forward-thinking strategies in construction and industrial applications, where resilience and high performance are primary considerations. Ultimately, choosing high quality grating steel signifies a commitment to excellence in both safety and functionality, a testament to its indispensable role in the current industrial landscape. Its ability to adapt to various applications while maintaining robust performance is why seasoned professionals in the industry continue to rely on it as a critical component in their design and construction efforts, underscoring its importance well into the future.

Latest news

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025