-

+86 15030157877

-

sales@galvanizedmetalmesh.com

okt . 14, 2025 16:49 Terug naar lijst

Need Square Wire Mesh—High Quality, Custom, Wholesale?

Square Wire Mesh: what buyers are really asking now

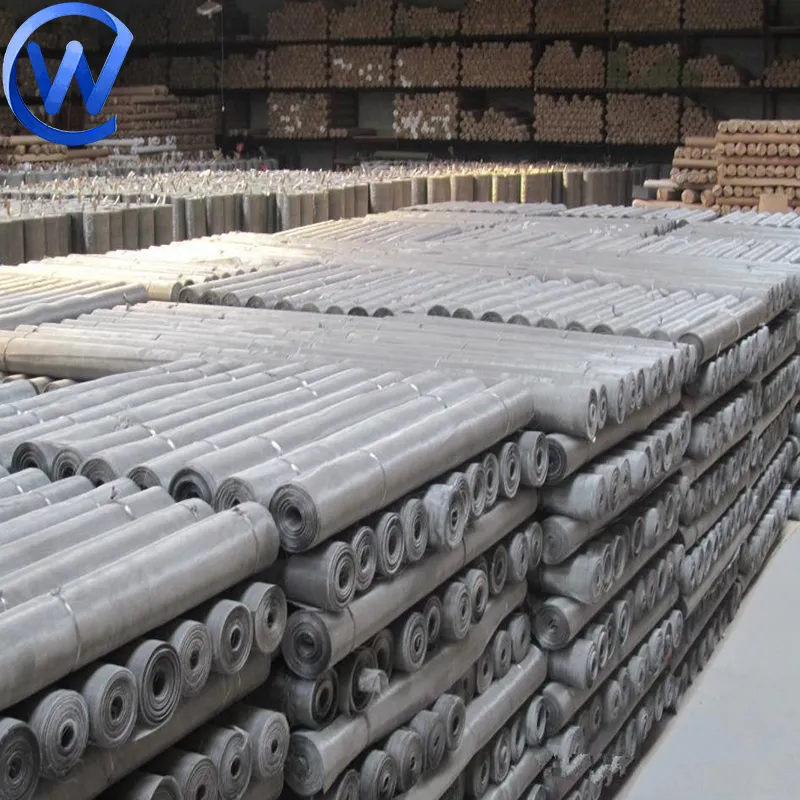

If you're sourcing square wire mesh, you’ve probably noticed two big shifts this year: more buyers moving from electro-galv to hot-dip after weaving, and stricter QA around aperture tolerance for sieving lines. To be honest, both trends make sense. Factory managers I talk to want fewer line stoppages and longer service life, not just a low unit price. Our reference product here comes out of South Industrial Zone 07, Anping County, Hebei, China—still the global heartland for woven metal mesh.

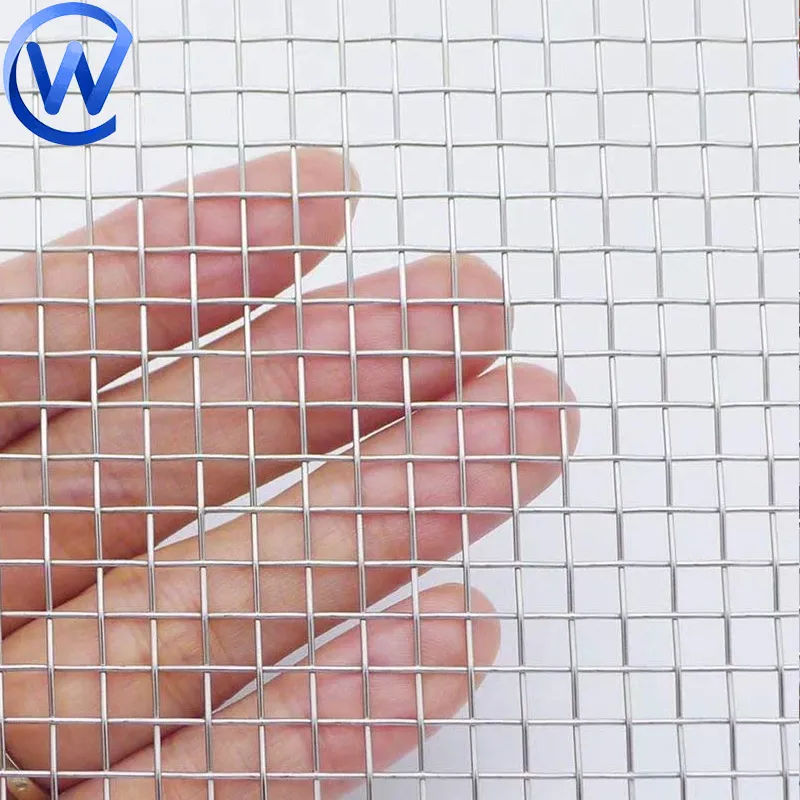

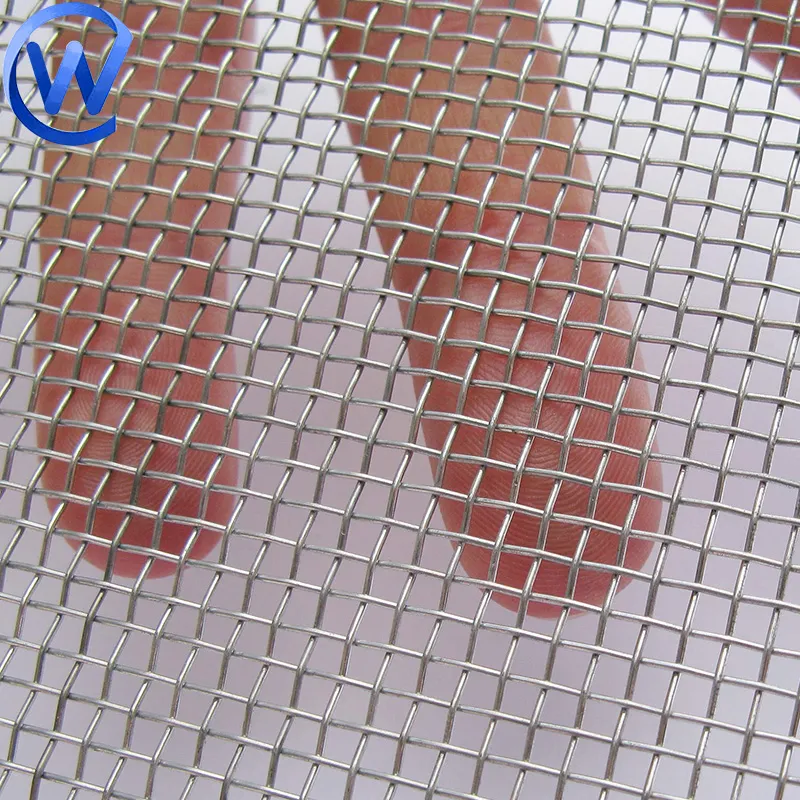

What it is, and where it’s used

The classic square wire mesh is a plain-woven, low-carbon steel cloth, zinc-coated either before or after weaving. It shows up everywhere: window screens in tropical builds, industrial sieves in sugar refineries and chemical plants, pre-screens on stone crushers, and even in grain cleaning lines on older mills. It’s not glamorous—but when the aperture is stable and the zinc layer is right, it just works.

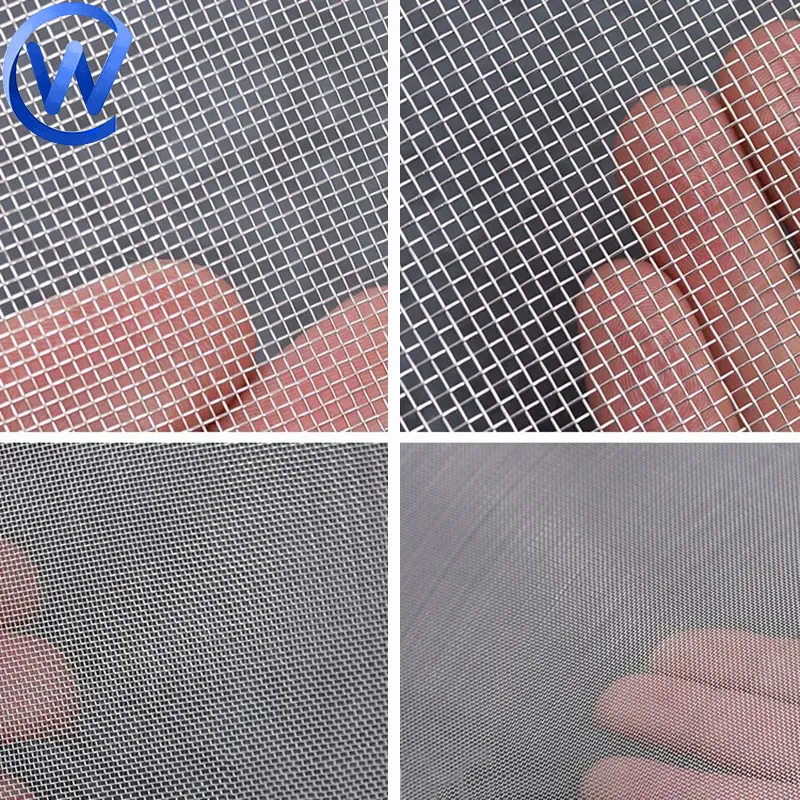

Core specs (real-world ranges)

| Mesh count (per inch) | Wire dia (mm) | Aperture ≈ (mm) | Rolbreedte | Zinc mass | Weight ≈ (kg/m²) |

|---|---|---|---|---|---|

| 4 | 1.20 | ≈5.15 | 0.9–1.5 m | 50–180 g/m² (HDG); 15–30 g/m² (EG) | ≈3.6 |

| 6 | 0.80 | ≈3.43 | 1.0–1.2 m | 50–180 / 15–30 | ≈2.2 |

| 10 | 0.55 | ≈1.99 | 1.0–1.5 m | 50–140 / 15–25 | ≈1.6 |

| 14 | 0.40 | ≈1.41 | 1.2 m | 50–120 / 15–25 | ≈1.2 |

| 20 | 0.35 | ≈0.92 | 1.0 m | 40–100 / 10–20 | ≈1.1 |

Notes: HDG = hot-dip galvanized; EG = electro-galvanized. Real-world use may vary by batch and environment.

Process and QA (what matters on the line)

- Material: low-carbon steel (Q195/Q235), annealed for ductility; zinc per ASTM A641 / EN 10244-2 classes.

- Methods: hot-dipped galvanized before or after; weaving by plain weave; electric galvanized options for cost-sensitive windows.

- Inspection: aperture tolerance per ASTM E2016; wire dia mic’d every ≈1,000 m; zinc mass by gravimetric test; edges flattened and trimmed.

- Test data: 96–240 h ASTM B117 salt spray (HDG, 100 g/m²) with no red rust; tensile 350–550 MPa typical.

- Service life: rural 8–12 yrs (HDG after weaving), 3–5 yrs (EG); coastal may be half, honestly.

Vendor snapshot (why quotes differ)

| Vendor | Origin | Coating | Standards/Certs | Lead time | MOQ | Notes |

|---|---|---|---|---|---|---|

| Anping Factory (focus) | South Industrial Zone 07, Anping, Hebei | HDG before/after; EG | ISO 9001; ASTM A641; EN 10244-2 | ≈7–15 days | ≈100 m² | Best for square wire mesh in industrial grades |

| EU Stockist | Central/Eastern EU | Pre-galv (EG) | EN 10244-2 | 3–5 days | 1 roll | Fast, but pricier per m² |

| Budget Importer | Various, Asia | Thin EG | — | 20–30 days | ≥500 m² | Watch zinc uniformity; mixed feedback |

Applications, customization, and lived-in feedback

- Window screen: light EG square wire mesh, 14–20 mesh, neat edges reduce snagging during install.

- Sugar/chemical sieving: 6–14 mesh HDG-after; tighter aperture tolerance cuts oversize by ≈2–3% (customer claim).

- Stone crusher pre-screen: 4–6 mesh with 1.0–1.2 mm wire; many customers say the after-weave hot-dip survives better against fines and wash.

- Customization: slit-to-width rolls, longer rolls (up to 50 m), reinforced edges, passivation topcoat for coastal jobs.

Case notes: a Gujarat sugar mill reported two extra months per set on HDG-after; a South African quarry cut weekly changeouts to biweekly; a Polish bakery switched to 10-mesh EG for cost, then upgraded to HDG-after on wet days—surprisingly, downtime fell more than the accountant expected.

Final checklist

- Confirm zinc class (g/m²), not just “galvanized.”

- Ask for aperture and wire-diameter tolerance vs ASTM E2016 class.

- For coastal or washdown, pick HDG after weaving; specify salt-spray hours target.

- Request batch test sheets + ISO 9001 certificate; some buyers also ask for RoHS/REACH statements.

Authoritative references

- ASTM A641/A641M – Zinc-Coated (Galvanized) Carbon Steel Wire.

- EN 10244-2 – Steel wire and wire products. Non-ferrous metallic coatings on steel wire. Zinc or zinc-alloy coatings.

- ASTM E2016 – Industrial Woven Wire Cloth Standard Specification.

- ISO 1461 – Hot dip galvanized coatings on fabricated iron and steel articles (relevant for after-weave HDG).

- ASTM B117 – Standard Practice for Operating Salt Spray (Fog) Apparatus.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

NieuwsNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

NieuwsNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

NieuwsNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

NieuwsNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

NieuwsNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

NieuwsNov.11,2025