-

+86 15030157877

-

sales@galvanizedmetalmesh.com

dec . 09, 2024 14:50 Back to list

perforated metal panel manufacturer

Perforated Metal Panel Manufacturers Innovating Architecture and Design

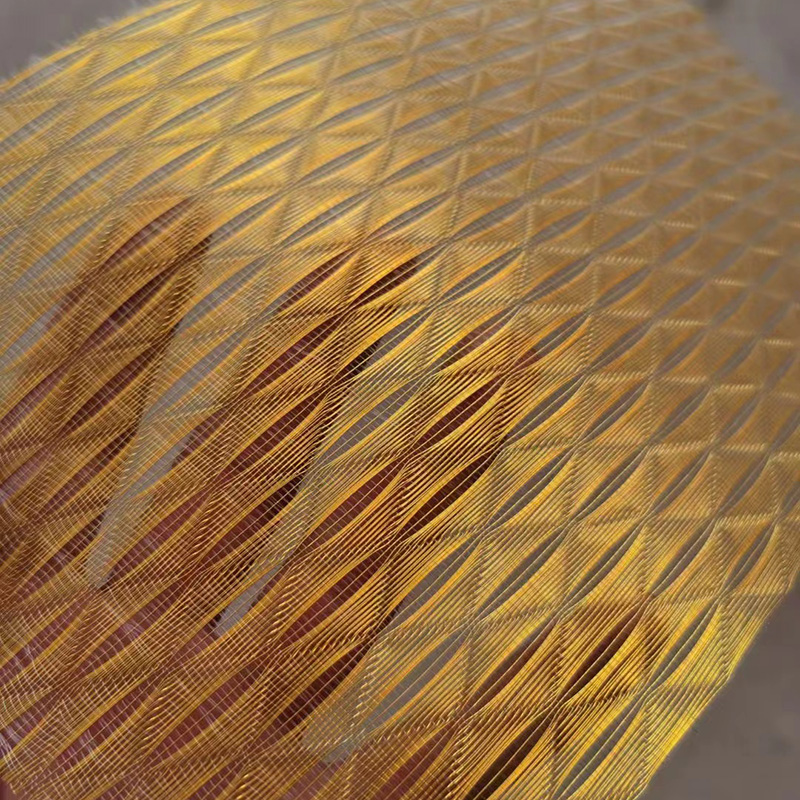

In recent years, perforated metal panels have gained significant popularity in various design and architectural applications due to their versatility, aesthetic appeal, and functional benefits. These panels, characterized by their distinct holes or patterns, are manufactured by industry leaders that specialize in producing high-quality metal products tailored to meet the demands of different projects. Understanding the role of perforated metal panel manufacturers is essential for architects, designers, and builders who are looking to incorporate these innovative materials into their work.

Perforated metal panels serve a wide array of uses, ranging from façade cladding and sunshades in modern buildings to decorative elements and functional screens. Their design allows for the passage of light and air while still providing privacy and protection from external elements. These features make them particularly appealing for sustainable architecture, where energy consumption and environmental impact are of utmost importance. By utilizing perforated panels, architects can create structures that are not only visually stunning but also energy-efficient, as these panels enhance natural ventilation and reduce reliance on artificial lighting.

One of the defining characteristics of perforated metal is the ability to customize the size, shape, and pattern of the holes according to specific project requirements. This customization is a key selling point for many manufacturers in this field. Manufacturers offer advanced design capabilities that allow clients to choose from a variety of materials, including aluminum, stainless steel, and carbon steel, each with its own unique properties and finishes. The choice of material significantly impacts the panel's durability, weight, and corrosion resistance, making it essential for manufacturers to educate their clients about the ideal choices for their specific applications.

perforated metal panel manufacturer

The manufacturing process of perforated metal panels involves several advanced techniques, including laser cutting, punching, and CNC machining. These processes ensure precision and accuracy in creating intricate designs that meet client specifications. Manufacturers also prioritize quality control throughout production, conducting rigorous testing to ensure that the panels meet industry standards. This focus on quality not only enhances the aesthetic appeal of the final product but also guarantees its longevity and reliability in demanding environments.

Furthermore, leading perforated metal panel manufacturers understand the importance of collaboration with architects and designers. They often work closely with their clients from the initial conception phase to ensure that the panels align with the overall vision of the project. This collaborative approach fosters innovation and creativity, resulting in unique design solutions that set projects apart. By leveraging advanced software for simulation and modeling, manufacturers can provide insights into the potential performance and aesthetic outcomes of their panels before production begins.

Sustainability is another critical consideration for perforated metal panel manufacturers. Many companies in the industry are adopting eco-friendly practices, such as using recyclable materials and implementing energy-efficient production techniques. This commitment to sustainability not only appeals to environmentally conscious consumers but also aligns with global trends towards greener building practices. In addition, the panels themselves can contribute to sustainable architecture by enhancing energy efficiency, supporting local climates, and utilizing renewable resources whenever possible.

In conclusion, perforated metal panel manufacturers play an integral role in modern architecture and design, offering innovative solutions that balance functionality with aesthetic appeal. Their ability to provide customized products tailored to specific project needs, combined with a commitment to quality and sustainability, positions them as key partners in the construction and design industries. As architects and designers continue to explore new ways to push the boundaries of creativity and sustainability in their projects, the expertise and offerings of perforated metal panel manufacturers will undoubtedly remain in high demand. Embracing these materials not only elevates design but also encourages a forward-thinking approach to architecture, making a lasting impact on both the industry and the environment.

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025

-

Reliable Perforated Stainless Steel Sheets Custom Designs & Export

NewsJun.09,2025