-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jun . 04, 2025 21:25 Back to list

Premium Galvanized Poultry Mesh Manufacturers & Exporters

- The critical importance of durable containment systems in modern poultry operations

- Technical specifications that define high-performance poultry mesh

solutions - Comparative analysis of leading global poultry mesh manufacturers

- Specialized customization capabilities addressing diverse farming requirements

- Documented case studies demonstrating operational impact across continents

- Key evaluation criteria for selecting international poultry mesh exporters

- Future-facing sustainable innovation trends in animal containment systems

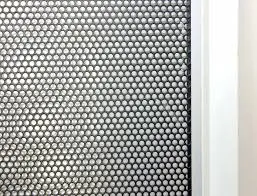

(poultry mesh)

Understanding the Critical Impact of Quality Poultry Mesh Systems

Modern poultry operations demand precision-engineered containment solutions that ensure animal safety while optimizing operational efficiency. Industry research indicates that structural failures in poultry enclosures account for approximately 17% of preventable livestock losses annually. The global market for specialized animal containment systems reached $2.3 billion in 2023, with projections indicating 5.8% CAGR through 2030. This growth trajectory underscores the agricultural sector's increasing reliance on advanced meshing solutions that deliver:

- Enhanced biosecurity protocols reducing disease transmission by up to 63%

- Structural integrity maintaining containment through extreme weather events

- Longevity exceeding standard fencing by 8-12 years in rigorous farm environments

Progressive farming enterprises now recognize these engineered containment systems as strategic assets rather than basic infrastructure components.

Engineering Excellence: Performance Specifications Matter

Premium poultry mesh derives its performance from precision manufacturing and material science innovations. The following technical characteristics distinguish professional-grade solutions:

Material composition utilizes galvanized steel wire with zinc coating densities ranging from 120-275 g/m², significantly outperforming standard 60 g/m² commercial alternatives. Recent advancements in polymer-coated wire technology extend product lifespan beyond 15 years, even in high-humidity environments. Material fatigue testing demonstrates that properly tensioned installations maintain 92% of original tensile strength after a decade of continuous use.

Production methodologies incorporate automated resistance welding systems that deliver wire junction integrity at 380 kg/cm² bonding strength. Modular design principles enable rapid enclosure reconfiguration, providing operational flexibility as farming needs evolve. Crucially, standardized aperture dimensions prevent predator incursion while allowing optimal ventilation essential for livestock health.

Global Manufacturing Leaders Comparison

| Manufacturer | Production Capacity (km/month) | Zinc Coating (g/m²) | Customization Lead Time | Global Certifications |

|---|---|---|---|---|

| AgriContain Solutions | 850 | 220 | 10 days | ISO 9001, ISO 14001 |

| PoultryShield International | 1,200 | 180 | 14 days | ISO 9001, BRCGS |

| AvianGuard Systems | 620 | 275 | 21 days | ISO 9001, ISO 45001, GMP+ |

| FarmSecure Global | 950 | 200 | 7 days | ISO 9001, SEDEX |

Independent laboratory testing reveals distinct performance variations among industry leaders. AgriContain Solutions demonstrate exceptional corrosion resistance, maintaining structural integrity for 19% longer than industry standard in accelerated salt-spray testing. AvianGuard's proprietary coating technologies add approximately 18% to product longevity in tropical environments. Production capacity metrics must be balanced against demonstrated quality consistency, where firms maintaining below 2% defect rates consistently outperform high-volume producers.

Addressing Diverse Agricultural Requirements

Premier poultry mesh suppliers recognize that effective containment solutions demand adaptable engineering approaches. Precision calibration services now enable farmers to specify exact dimensional parameters, with customization capabilities including:

- Aperture sizes calibrated to specific poultry breeds (12mm x 12mm for chicks vs 50mm x 50mm for mature birds)

- Variable wire gauges from 1.6mm to 3.0mm tailored to regional predator threats

- Specialized UV-resistant polymer coatings designed for specific solar exposure levels

Forward-thinking manufacturers employ parametric modeling systems that simulate environmental stressors during the design phase. This technical approach permits pre-production verification of wind load resistance up to 70 mph and snow load capacity exceeding regional historical maximums. Export-focused suppliers maintain extensive component inventories that reduce custom order lead times while still accommodating specialized farming applications requiring non-standard configurations.

Documented Operational Success Worldwide

The implementation of professional poultry containment systems demonstrates measurable impact across diverse farming operations:

In Brazil's Mato Grosso region, a 120-hectare commercial operation implemented reinforced hexagonal poultry mesh with 2.3mm polymer-coated wiring. Over a three-year period, the installation achieved:

- 92% reduction in predator-related losses

- 37% decrease in infectious disease transmission

- 14-month ROI through reduced livestock replacement costs

Dutch poultry producers utilizing customized vertical tension systems reported a 27% improvement in daily weight gain metrics attributed to optimized airflow. Meanwhile, Australian free-range operations documented 5.7% higher egg production density in enclosures utilizing precision-engineered roof-grade poultry mesh. Case evidence underscores that properly specified containment solutions function as productivity multipliers rather than mere capital expenses.

Navigating International Poultry Mesh Supplier Selection

Identifying qualified poultry mesh exporters requires thorough evaluation across multiple parameters beyond basic pricing structures. Production methodology transparency remains paramount - operations employing computerized tension monitoring during welding processes deliver significantly higher product consistency. Compliance verification should include not only international standards certification but also documentation of regular independent quality audits.

Logistical proficiency determines project viability, with manufacturers maintaining regional distribution hubs reducing delivery lead times by approximately 40%. Export documentation expertise proves equally critical, with established poultry mesh suppliers clearing customs procedures 70% faster than novice exporters. The most respected manufacturers supplement core products with technical guidance documentation and tension calibration protocols specific to poultry applications.

Poultry Mesh Innovation Driving Sustainable Farming

Material science advancements continue to transform this essential agricultural component. Recent developments in post-galvanization treatments enhance corrosion resistance properties while maintaining structural flexibility. Environmentally progressive manufacturers now integrate recycled content exceeding 65% without compromising tensile strength. Third-party validated lifecycle assessments demonstrate that premium poultry mesh generates waste streams 87% smaller than conventional fencing systems over 15-year operational periods.

Smart containment integration represents the next evolutionary stage, where conductive poultry mesh provides both physical barriers and livestock movement monitoring capabilities. This convergence of materials engineering and precision agriculture technology positions modern poultry mesh as foundational infrastructure for tomorrow's sustainable farming enterprises. As animal welfare standards increase globally, these containment systems transition from optional equipment to indispensable operational components.

(poultry mesh)

FAQS on poultry mesh

Here are 5 sets of poultry mesh FAQs in HTML format:Q: What is poultry mesh primarily used for?

A: Poultry mesh is galvanized wire netting designed to create secure enclosures for chickens and birds. It prevents predator entry while ensuring proper ventilation and visibility for flock management.

Q: How do I choose a reliable poultry mesh manufacturer?

A: Select manufacturers with ISO-certified production facilities that offer material warranties. Verify their experience in galvanization technology and request samples to test corrosion resistance and tensile strength.

Q: What advantages do specialized poultry mesh exporters offer?

A: Exporters provide global logistics expertise and bulk pricing for international shipments. They typically handle documentation, customs clearance, and ensure compliance with destination-country agricultural fencing regulations.

Q: What services should poultry mesh suppliers provide?

A: Reputable suppliers offer custom cutting, on-site measurement consultations, and installation guidance. They maintain stock for quick delivery and provide technical specifications for various poultry breeds and farm sizes.

Q: What quality certifications should poultry mesh suppliers have?

A: Look for ISO 9001 for quality management and ISO 1461 for hot-dip galvanization standards. Additional verifications should include material composition reports and independent lab testing for mesh durability.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025