-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 25, 2025 04:20 Back to list

welded panel factories

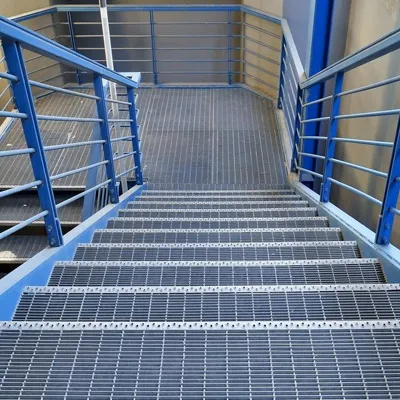

Welded panels have become an indispensable component across various industries due to their robustness, versatility, and long-lasting nature. These panels, crafted through a combination of skillful engineering and innovative technology, serve multiple purposes, ranging from boundary security to architectural aesthetics.

Industry experts highlight that choosing the right type of welded panel is crucial for optimizing performance and longevity. Panels come in varying materials such as stainless steel, galvanized steel, and PVC-coated variants, each providing specific benefits. Stainless steel panels are ideal for environments exposed to harsh weather conditions due to their corrosion resistance, while PVC-coated panels offer additional aesthetic flexibility and protection against UV rays. The authoritative voice in the industry underscores the importance of proper installation and maintenance practices to maximize the lifespan of welded panels. Professional installation ensures that the panels are securely anchored, preventing potential failures or safety hazards. Routine inspections and timely interventions, like cleaning and minor repairs, further boost the panels' functionality and durability. Trustworthiness in the choice of welded panels can significantly impact the efficacy of their application. Reputable manufacturers provide warranties and certifications that testify to the quality and safety standards of their products. It is advised for consumers to verify these credentials, as this assures them of the product's integrity and capability to meet specified requirements. Furthermore, technological advancements have introduced enhancements such as anti-climb features and electric conducting designs, catering to high-security needs in prisons and sensitive installations. Specialists in security design commend these innovations as they offer superior protection while blending with the existing security infrastructure. In summary, welded panels represent more than just a construction material; they are a testament to enduring quality and multifunctionality. Their adaptability to various applications, coupled with ease of installation and maintenance, makes them an invaluable asset across diverse domains. As industry specialists continue to innovate, the future of welded panels promises even greater efficiency and applicability, fortifying their position as a cornerstone in modern construction and design.

Industry experts highlight that choosing the right type of welded panel is crucial for optimizing performance and longevity. Panels come in varying materials such as stainless steel, galvanized steel, and PVC-coated variants, each providing specific benefits. Stainless steel panels are ideal for environments exposed to harsh weather conditions due to their corrosion resistance, while PVC-coated panels offer additional aesthetic flexibility and protection against UV rays. The authoritative voice in the industry underscores the importance of proper installation and maintenance practices to maximize the lifespan of welded panels. Professional installation ensures that the panels are securely anchored, preventing potential failures or safety hazards. Routine inspections and timely interventions, like cleaning and minor repairs, further boost the panels' functionality and durability. Trustworthiness in the choice of welded panels can significantly impact the efficacy of their application. Reputable manufacturers provide warranties and certifications that testify to the quality and safety standards of their products. It is advised for consumers to verify these credentials, as this assures them of the product's integrity and capability to meet specified requirements. Furthermore, technological advancements have introduced enhancements such as anti-climb features and electric conducting designs, catering to high-security needs in prisons and sensitive installations. Specialists in security design commend these innovations as they offer superior protection while blending with the existing security infrastructure. In summary, welded panels represent more than just a construction material; they are a testament to enduring quality and multifunctionality. Their adaptability to various applications, coupled with ease of installation and maintenance, makes them an invaluable asset across diverse domains. As industry specialists continue to innovate, the future of welded panels promises even greater efficiency and applicability, fortifying their position as a cornerstone in modern construction and design.

Next:

Latest news

-

High-Quality Security Fence Supplier & Manufacturer Leading Exporter

NewsJun.24,2025

-

High-Quality Concrete Reinforcement Wire Mesh Leading Manufacturers & Exporters

NewsJun.10,2025

-

High Quality Galvanized Steel Fence - Leading Manufacturer, Exporter & Supplier

NewsJun.10,2025

-

10 Gauge Barbed Wire Supplier - Heavy-Duty & Corrosion-Resistant

NewsJun.10,2025

-

Durable Farm Fence Wire Suppliers & Manufacturers Fence Wire

NewsJun.10,2025

-

Premium Powder Coated Metal Mesh Suppliers - Durable & Rust-Resistant

NewsJun.09,2025