-

+86 15030157877

-

sales@galvanizedmetalmesh.com

jan . 09, 2025 10:56 Back to list

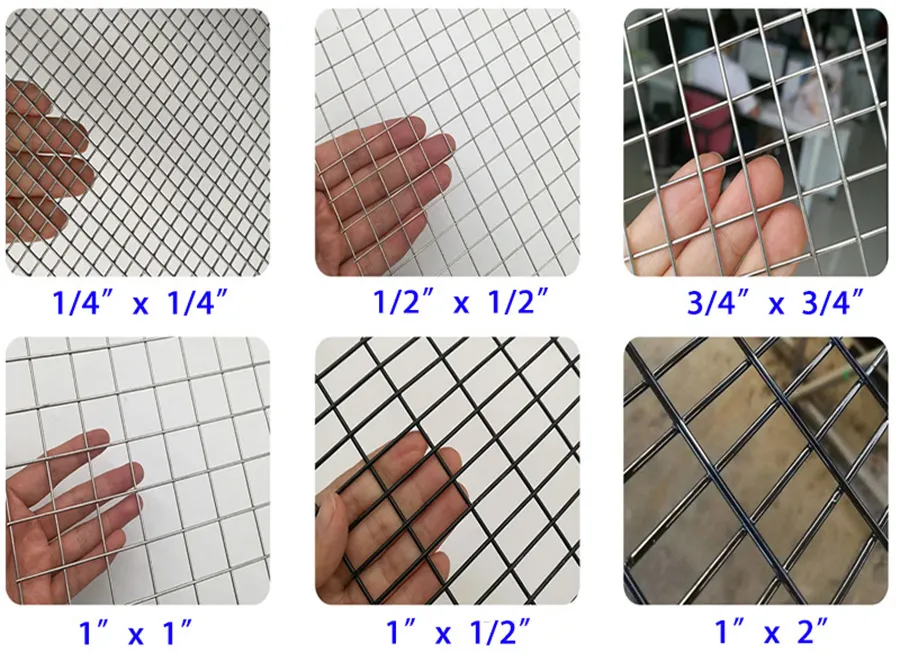

galvanized welded wire mesh

Welded wire mesh stands as a cornerstone in the construction and fabrication industries, evolving over the years to fortify structures with its unparalleled integrity and versatility. This essential material, made by joining metal wires at intersections using electric resistance welding, serves various domains, from residential constructions to large-scale industrial projects.

Trustworthiness of welded wire mesh is anchored in its rigorous testing and certification processes. Each batch undergoes stringent quality checks to maintain consistency in strength and performance. These quality assurance measures are essential in providing architects and builders with the confidence that their designs will stand the test of time. Furthermore, the environmental considerations associated with welded wire mesh cannot be overlooked. As sustainability becomes a priority in construction, the recyclable nature of steel makes this mesh a preferred choice for eco-conscious projects. Its ability to be repurposed without loss of quality aligns with global efforts to reduce waste and promote sustainable building practices. The authoritative presence of welded wire mesh in the industry is undeniable. Leading construction experts and engineers continuously endorse its application, underpinned by a history of successful implementations across diverse projects worldwide. The collective expertise of experienced professionals drives innovation, pushing the boundaries of what welded wire mesh can accomplish. In conclusion, welded wire mesh remains a vital component in the toolkit of modern construction experts. Its combination of durability, adaptability, and sustainability ensures it remains a trusted choice for reinforcing and protecting structures in an ever-evolving architectural landscape. By adhering to stringent quality standards and leveraging advanced metallurgical techniques, welded wire mesh stands not only as a testament to engineering prowess but also as a guardian of structural integrity for future generations.

Trustworthiness of welded wire mesh is anchored in its rigorous testing and certification processes. Each batch undergoes stringent quality checks to maintain consistency in strength and performance. These quality assurance measures are essential in providing architects and builders with the confidence that their designs will stand the test of time. Furthermore, the environmental considerations associated with welded wire mesh cannot be overlooked. As sustainability becomes a priority in construction, the recyclable nature of steel makes this mesh a preferred choice for eco-conscious projects. Its ability to be repurposed without loss of quality aligns with global efforts to reduce waste and promote sustainable building practices. The authoritative presence of welded wire mesh in the industry is undeniable. Leading construction experts and engineers continuously endorse its application, underpinned by a history of successful implementations across diverse projects worldwide. The collective expertise of experienced professionals drives innovation, pushing the boundaries of what welded wire mesh can accomplish. In conclusion, welded wire mesh remains a vital component in the toolkit of modern construction experts. Its combination of durability, adaptability, and sustainability ensures it remains a trusted choice for reinforcing and protecting structures in an ever-evolving architectural landscape. By adhering to stringent quality standards and leveraging advanced metallurgical techniques, welded wire mesh stands not only as a testament to engineering prowess but also as a guardian of structural integrity for future generations.

Latest news

-

Gabion Fence Manufacturer & Exporter Durable, Custom Solutions

NewsMay.16,2025

-

High-Security Concertina Razor Barbed Wire Durable & ISO-Certified

NewsMay.16,2025

-

Premium Livestock Fence Suppliers Durable & Custom Solutions

NewsMay.15,2025

-

Durable Rust Proof Razor Barbed Wire Exporters & Suppliers

NewsMay.15,2025

-

Premium Stainless Steel Barbed Wire Supplier Durable & Corrosion-Resistant

NewsMay.15,2025

-

Square Mesh Suppliers & Exporters Durable & Versatile Solutions

NewsMay.14,2025