-

+86 15030157877

-

sales@galvanizedmetalmesh.com

nov . 17, 2024 16:53 Back to list

welded wire mesh manufacturer

Understanding the Importance of Welded Wire Mesh in Construction

Welded wire mesh has emerged as a vital component in various construction projects, providing strength, durability, and versatility to structures. As a welded wire mesh manufacturer, we understand the intricacies involved in the production and application of this crucial material. In this article, we will explore the advantages of welded wire mesh, its applications, and why choosing the right manufacturer is essential for quality and reliability.

What is Welded Wire Mesh?

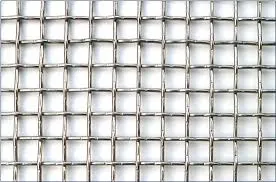

Welded wire mesh is a grid-like structure formed by welding together wires at their intersections. This process creates a strong and uniform mesh that can be produced in various sizes, shapes, and wire diameters to suit different needs. Typically made from galvanized or stainless steel, welded wire mesh is resistant to corrosion and offers a high tensile strength, making it a preferred choice in various industries.

Advantages of Welded Wire Mesh

1. Strength and Durability One of the most significant benefits of welded wire mesh is its inherent strength. The welding process ensures that the wires are securely attached to one another, providing a stable and robust framework. This makes it ideal for reinforcing concrete slabs, walls, and foundations, ensuring long-lasting structural integrity.

2. Cost-Effectiveness Compared to other reinforcement methods, welded wire mesh often proves to be more economical. Its efficient design allows for faster installation, reducing labor costs. Additionally, the long lifespan of this material minimizes the need for frequent replacements, further enhancing its cost-effectiveness.

3. Versatility Welded wire mesh is incredibly versatile, making it suitable for a wide array of applications. From construction and infrastructure projects to agricultural uses, it can be adapted to meet specific requirements. Whether it’s used for concrete reinforcement, fencing, or as a support system for landscaping, welded wire mesh proves to be beneficial across various fields.

4. Easy Installation The uniformity of welded wire mesh facilitates ease of handling and installation. It can be quickly cut to size and installed, helping contractors save time during construction. This efficiency is crucial in meeting tight project deadlines without compromising on quality.

5. Aesthetic Appeal Beyond its functional benefits, welded wire mesh can also enhance the aesthetic appeal of a structure. It can be used in architectural designs, providing a modern look while serving practical purposes. Designers appreciate the ability to incorporate welded mesh into buildings, fences, and other structures as both a functional and decorative element.

Applications of Welded Wire Mesh

Welded wire mesh is utilized in various sectors, including

welded wire mesh manufacturer

- Construction The primary application of welded wire mesh is in the construction industry, where it is used to reinforce concrete and masonry structures

. It helps control cracking and provides tensile strength, especially in slabs, walls, and foundations.- Agriculture Farmers use welded wire mesh for fencing, animal enclosures, and gardening supports. Its durability ensures that it can withstand harsh weather conditions while protecting livestock and crops.

- Industrial In industrial settings, welded wire mesh is utilized for safety barriers, racks, and storage solutions. It provides a robust option for securing areas and organizing equipment.

- Civil Engineering Various civil engineering projects use welded wire mesh for retaining walls, bridge construction, and roadwork. Its strength is crucial in handling the loads associated with these structures.

Choosing the Right Welded Wire Mesh Manufacturer

When selecting a welded wire mesh manufacturer, several factors should be taken into account

1. Quality of Materials Ensure that the manufacturer uses high-quality materials, such as galvanized or stainless steel, to produce their welded wire mesh. This guarantees durability and longevity.

2. Customization Options Look for manufacturers who offer customization in terms of sizes and specifications. This ensures that you get a product tailored to your specific project needs.

3. Reputation and Reliability Research the manufacturer’s reputation in the industry. Reading reviews, testimonials, and case studies can provide insights into their reliability and service quality.

4. Competitive Pricing While cost should not be the only factor, it's essential to find a manufacturer who offers competitive pricing without compromising on quality.

In conclusion, welded wire mesh is a crucial material in modern construction, offering numerous advantages that enhance the strength, versatility, and aesthetic appeal of structures. As a committed welded wire mesh manufacturer, we strive to deliver high-quality products that meet the diverse needs of our clients, ensuring the success of their projects. Whether it's for construction, agriculture, or industrial purposes, investing in quality welded wire mesh is a decision that can lead to long-term benefits.

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025