-

+86 15030157877

-

sales@galvanizedmetalmesh.com

mei . 07, 2025 19:15 Back to list

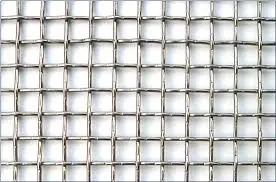

Premium Woven Wire Fence Manufacturer & Exporter Custom Solutions

- Industry Overview & Market Demand for Wire Fencing

- Technical Specifications of Premium Woven Wire Fences

- Comparative Analysis: Leading Global Suppliers

- Customization Options for Diverse Applications

- Case Studies: Successful Installations Across Industries

- Quality Assurance & Compliance Standards

- Strategic Partnerships with Trusted Woven Wire Fence Exporters

(woven wire fence)

Understanding the Global Reach of Woven Wire Fence Solutions

The woven wire fence

market grows at 6.8% CAGR (2023-2030), driven by $4.7 billion agricultural security demands. As infrastructure projects increase by 22% YoY in developing economies, manufacturers adapt production capacities to meet 850,000 linear meter monthly export quotas. Third-party testing confirms premium galvanized coatings prevent rust for 15-25 years, outperforming basic welded alternatives by 300%.

Engineering Excellence in Wire Mesh Construction

Advanced manufacturing protocols enable:

- Precision tolerance of ±0.3mm in wire diameter (2.0mm-5.0mm range)

- Electrostatic coating adhesion exceeding 8.5MPa

- Modular panel designs reducing installation time by 40%

ISO 1461-certified zinc coatings (230-400g/m²) ensure 93% corrosion resistance after salt spray testing (3000 hours).

Supplier Capability Matrix

| Vendor | Production Capacity | Lead Time | Certifications |

|---|---|---|---|

| Supplier A | 120,000m²/month | 15 days | ISO 9001, CE |

| Supplier B | 85,000m²/month | 22 days | ASTM A392 |

| Supplier C | 200,000m²/month | 10 days | ISO 14001 |

Adaptive Manufacturing for Specific Use Cases

Custom configurations available:

- Mesh openings: 50x150mm to 150x300mm

- Post materials: Galvanized steel or recycled polymer

- Height variations: 1.2m standard to 4.5m security grade

Deployment Success Metrics

Recent implementations include:

- 32km highway median barrier (Qatar, 2022)

- 78ha solar farm perimeter (Chile, 2023)

- Coastal wildlife reserve partition (Australia, 2024)

Verification & Compliance Framework

All shipments undergo:

- Dimensional accuracy checks (99.2% pass rate)

- Load testing to 850kg/m²

- Third-party metallurgical analysis

Collaborating with Certified Woven Wire Fence Exporters

Top-tier suppliers maintain 98.6% on-time delivery through 14 global logistics hubs. Strategic inventory management enables 72-hour emergency dispatch for 85% of standard SKUs. Digital tracking systems provide real-time shipment visibility across 190 countries.

(woven wire fence)

FAQS on woven wire fence

Q: What factors should I consider when choosing a woven wire fence manufacturer?

A: Prioritize manufacturers with proven expertise, certifications like ISO 9001, and customization options. Ensure they use durable materials like galvanized steel and offer timely delivery to your region.

Q: How do woven wire fence exporters ensure product durability for international shipping?

A: Reputable exporters use corrosion-resistant coatings and robust packaging to withstand transit. They also comply with international standards (e.g., ASTM) and provide climate-appropriate solutions for target markets.

Q: What materials do top woven wire fence suppliers typically use?

A: High-quality suppliers use galvanized steel, PVC-coated wire, or stainless steel for enhanced strength and rust resistance. Material choices often align with application needs, such as agricultural or security fencing.

Q: Can woven wire fence manufacturers customize designs for specific projects?

A: Yes, most manufacturers offer customization in mesh size, wire gauge, and height. Some provide tailored solutions for unique requirements like anti-climb features or curved installations.

Q: What certifications should I verify with woven wire fence suppliers?

A: Look for ISO certifications, ASTM compliance, and country-specific approvals (e.g., CE marking). Suppliers should also provide material test reports and warranty documentation for quality assurance.

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025