-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 25, 2024 08:49 Back to list

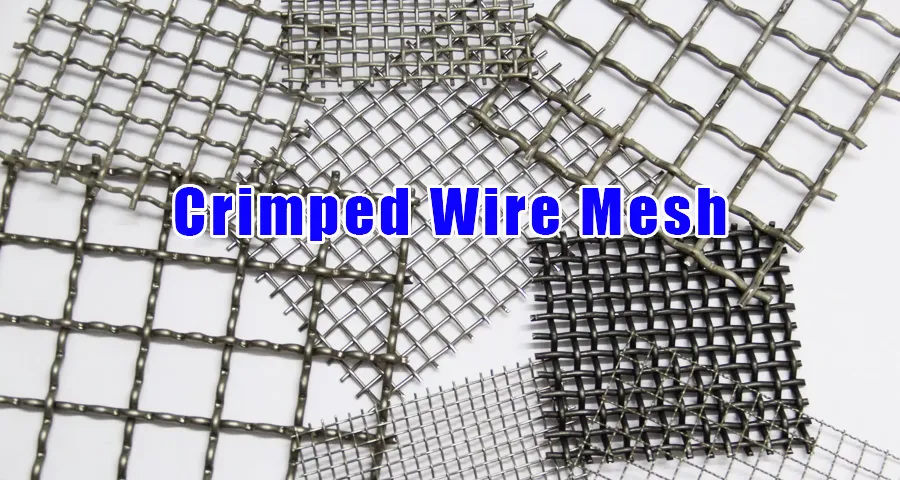

Durable Crimped Wire Mesh Solutions for Various Industrial Applications

The Versatility of Crimped Wire Mesh

Crimped wire mesh, a remarkable material known for its durability and functional design, has become increasingly popular in various industries. This unique type of wire mesh is characterized by its crimped pattern, which enhances its strength and flexibility, making it ideal for numerous applications. Its versatility, aesthetic appeal, and pragmatic features have made crimped wire mesh a preferred choice in construction, filtration, and even decorative projects.

Understanding Crimped Wire Mesh

Crimped wire mesh is produced by weaving together wires that have been crimped, or bent, at various angles. This crimping process introduces a series of waves into the wire, which allows for a more secure interlocking pattern. The result is a mesh that not only displays heightened structural integrity but also benefits from a reduced chance of deformation under stress. This unique configuration enables crimped wire mesh to bear significant loads while maintaining its shape, a critical property for many applications.

Applications in Construction

In construction, crimped wire mesh serves multiple purposes. It is often utilized in reinforced concrete applications, providing tensile strength and stability to various structures. Builders appreciate crimped wire mesh for its ability to form a solid foundation, as it helps reduce the risk of cracking in concrete due to temperature fluctuations. Additionally, its corrosion-resistant qualities make it suitable for outdoor projects, ensuring longevity even in challenging environments.

Filtration and Separation

crimped wire mesh

Beyond construction, crimped wire mesh plays a vital role in filtration and separation processes. Various industries, such as food production, water treatment, and mining, rely on crimped wire mesh to efficiently capture and separate different materials. The crimped structure allows for optimal fluid flow while preventing the passage of unwanted particles, making it an excellent choice for sieve screens and strainers. Its customizability also means that businesses can choose the specific mesh size and wire thickness to suit their unique filtration needs.

Aesthetic Applications

On the aesthetic front, crimped wire mesh has gained traction in interior design and architecture. Designers appreciate its modern and industrial look, which can enhance the visual appeal of spaces. Crimped wire mesh can be used for creating decorative partitions, railings, and even sculptures. Its versatility offers creative designers the ability to experiment with light and shadow, creating dynamic spaces that transform as one moves through them. The ability to powder-coat or finish the mesh in various colors further adds to its charm, making it suitable for contemporary applications.

Environmental Considerations

In today’s world, sustainability is a significant concern. Fortunately, crimped wire mesh can be an environmentally friendly choice. Typically made from recyclable materials, it aligns well with the growing demand for sustainable practices in manufacturing and construction. Its durability ensures that products last longer, ultimately contributing to waste reduction.

Conclusion

In summary, crimped wire mesh stands out as a truly versatile material that boasts strength, durability, and aesthetic appeal. Its applications in construction, filtration, and design highlight its multifaceted nature, making it a staple in various industries. As the demand for sustainable materials continues to rise, crimped wire mesh offers a solution that merges functionality with environmental consciousness. Whether used for practical purposes or decorative elements, crimped wire mesh is far more than just a utilitarian material; it is a testament to thoughtful design and engineering.

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025

-

3D Curved Welded Wire Mesh Fence for Secure & Stylish Fencing Solutions

NewsJul.28,2025

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025