-

+86 15030157877

-

sales@galvanizedmetalmesh.com

lut . 06, 2025 00:52 Back to list

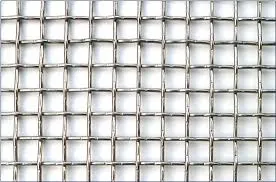

custom flat expanded metal mesh

The versatility and durability of custom flat expanded metal mesh make it an increasingly popular choice across a wide variety of industries. This innovative material combines structural integrity with aesthetic appeal, making it ideal for both functional and decorative applications. Its unique manufacturing process—where a sheet of metal is uniformly slit and stretched—results in a product that is not only cost-effective but also environmentally friendly, as it generates minimal waste.

Custom flat expanded metal mesh is also synonymous with excellent airflow and transparency. This attribute not only enhances the aesthetic value of a structure but also facilitates ventilation and light penetration, crucial for reducing energy consumption and improving comfort in architectural projects. From façade cladding to sunscreens, its implementation can lead to energy-efficient designs that capitalize on natural light and air circulation. As an authoritative figure in the industry, trustworthiness in delivering quality and adherence to timelines is key when dealing with custom metal mesh suppliers. Given the material's bespoke nature, partnering with manufacturers who are reliable and possess a demonstrable track record is indispensable. This ensures that all project specifications are met accurately, minimizing material waste and optimizing project costs. In summary, the adoption of custom flat expanded metal mesh represents an intersection of art and engineering. Its robust adaptability and strength, combined with its aesthetic possibilities, make it a sought-after solution across diverse industries. With a competent approach that balances practical needs and creative vision, this material continues to set standards for safety, efficiency, and design innovation. For those interested in leveraging this versatile material, working with experienced industry experts can provide valuable insights and guidance. Ultimately, custom flat expanded metal mesh stands as a testament to what modern material engineering can achieve when functionality meets creativity.

Custom flat expanded metal mesh is also synonymous with excellent airflow and transparency. This attribute not only enhances the aesthetic value of a structure but also facilitates ventilation and light penetration, crucial for reducing energy consumption and improving comfort in architectural projects. From façade cladding to sunscreens, its implementation can lead to energy-efficient designs that capitalize on natural light and air circulation. As an authoritative figure in the industry, trustworthiness in delivering quality and adherence to timelines is key when dealing with custom metal mesh suppliers. Given the material's bespoke nature, partnering with manufacturers who are reliable and possess a demonstrable track record is indispensable. This ensures that all project specifications are met accurately, minimizing material waste and optimizing project costs. In summary, the adoption of custom flat expanded metal mesh represents an intersection of art and engineering. Its robust adaptability and strength, combined with its aesthetic possibilities, make it a sought-after solution across diverse industries. With a competent approach that balances practical needs and creative vision, this material continues to set standards for safety, efficiency, and design innovation. For those interested in leveraging this versatile material, working with experienced industry experts can provide valuable insights and guidance. Ultimately, custom flat expanded metal mesh stands as a testament to what modern material engineering can achieve when functionality meets creativity.

Latest news

-

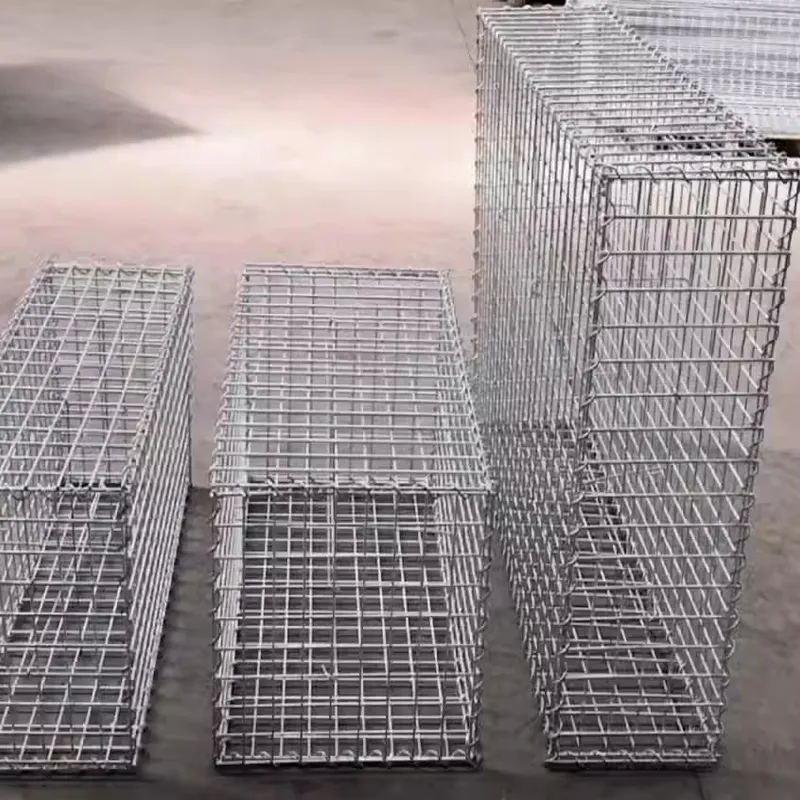

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025