-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 05, 2024 15:00 Back to list

custom mesh wire roll

Custom Mesh Wire Roll A Versatile Solution for Your Needs

In various industrial and DIY applications, custom mesh wire rolls have become a cornerstone due to their adaptability and solid construction. This material is not just a simple wire; it embodies a myriad of functionalities and can be tailored to meet specific requirements. Whether you’re in agriculture, construction, or manufacturing, custom mesh wire rolls can provide the solutions you need.

Understanding Custom Mesh Wire Rolls

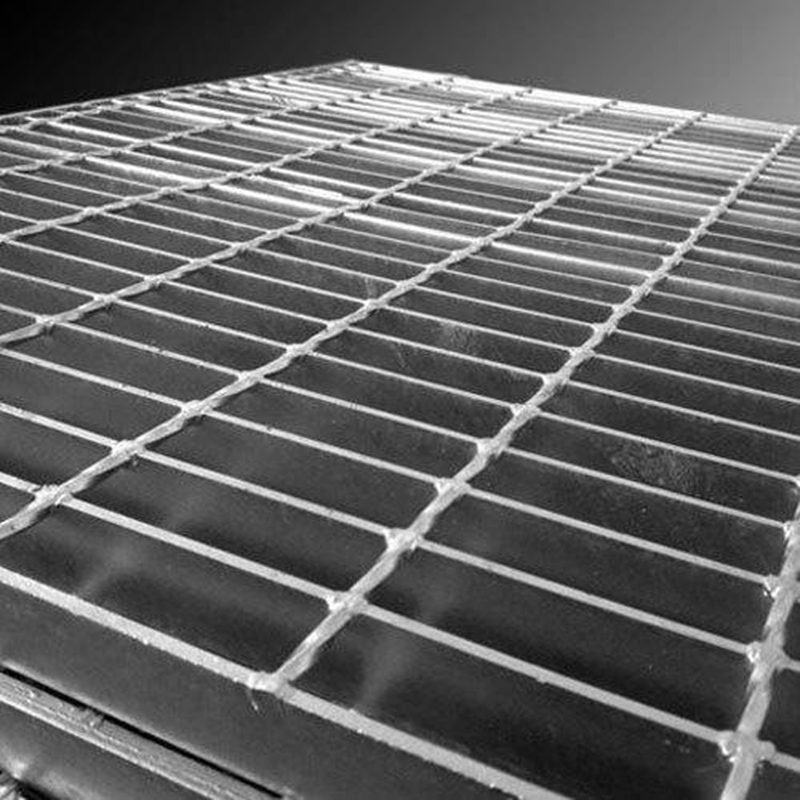

Custom mesh wire rolls are typically made from high-quality metal wire that is woven or welded together to create a mesh structure. The term custom indicates that these wire rolls can be designed to meet particular specifications, including dimensions, wire thickness, mesh size, and material type. This customization ensures that the mesh wire rolls cater to the diverse needs of different industries.

The materials used in manufacturing these wire rolls can vary—from stainless steel and galvanised steel to aluminum and PVC-coated wire. Each material has its unique benefits; for example, stainless steel offers exceptional durability and resistance to corrosion, making it ideal for outdoor applications. On the other hand, PVC-coated wire is often used in environments where added protection against the elements is required.

Applications of Custom Mesh Wire Rolls

1. Agriculture One of the most common uses of custom mesh wire rolls is in the agricultural sector. Farmers utilize these rolls for fencing, creating enclosures for livestock, and building trellises for plants. The mesh allows for airflow and sunlight while keeping animals contained and safe from predators. Furthermore, its customizable features make it easy to create required specifications for different crops and livestock.

2. Construction In construction, custom mesh wire rolls serve multiple purposes. They are widely used in reinforcing concrete structures, providing additional strength and stability. Welded wire mesh is commonly integrated into slabs, walls, and foundations. Moreover, this type of mesh is also used for safety barriers and scaffolding, ensuring worker safety on construction sites.

custom mesh wire roll

3. Manufacturing and Industrial Uses Many manufacturing industries rely on custom mesh wire for filtration and separation processes. Whether it’s a sieve for sifting materials or a filter for liquids, these mesh rolls can be designed to meet the specific needs of the application. Additionally, the automotive and aerospace industries utilize mesh wire in various components due to its lightweight properties combined with strength.

4. Security Custom mesh wire rolls are often employed for security purposes. In residential and commercial settings, they can be fashioned into fences to deter intruders while still allowing visibility. Security mesh is especially vital in places that require a balance between aesthetics and functionality.

Choosing the Right Custom Mesh Wire Roll

When selecting a custom mesh wire roll, there are several factors to consider. The first is the intended application—understanding how the wire will be used will greatly influence the type of mesh you need. For example, if the mesh is for outdoor use, rust-resistant materials should be prioritized.

Next, consider the dimensions and specifications required for your project. Customization allows for specific lengths and widths, ensuring that the mesh fits your needs perfectly. It's also important to measure the wire gauge and mesh opening size, as these factors will affect durability and functionality.

Conclusion

In summary, custom mesh wire rolls are an indispensable resource across various industries, offering flexibility, durability, and tailored solutions. Whether for agricultural use, construction, manufacturing, or security, the ability to customize these wire rolls makes them an ideal choice for numerous applications. By selecting the right materials and specifications, users can ensure that their custom mesh wire rolls meet the unique demands of their projects, ultimately contributing to efficiency, safety, and satisfaction. As the demand for such versatile materials continues to grow, the importance of understanding and utilizing custom mesh wire rolls cannot be overstated.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025