-

+86 15030157877

-

sales@galvanizedmetalmesh.com

wrz . 12, 2024 14:53 Back to list

Quality Galvanized Binding Wire Manufacturers - Durable & Reliable Solutions

The Role of Galvanized Binding Wire Manufacturers in Modern Industries

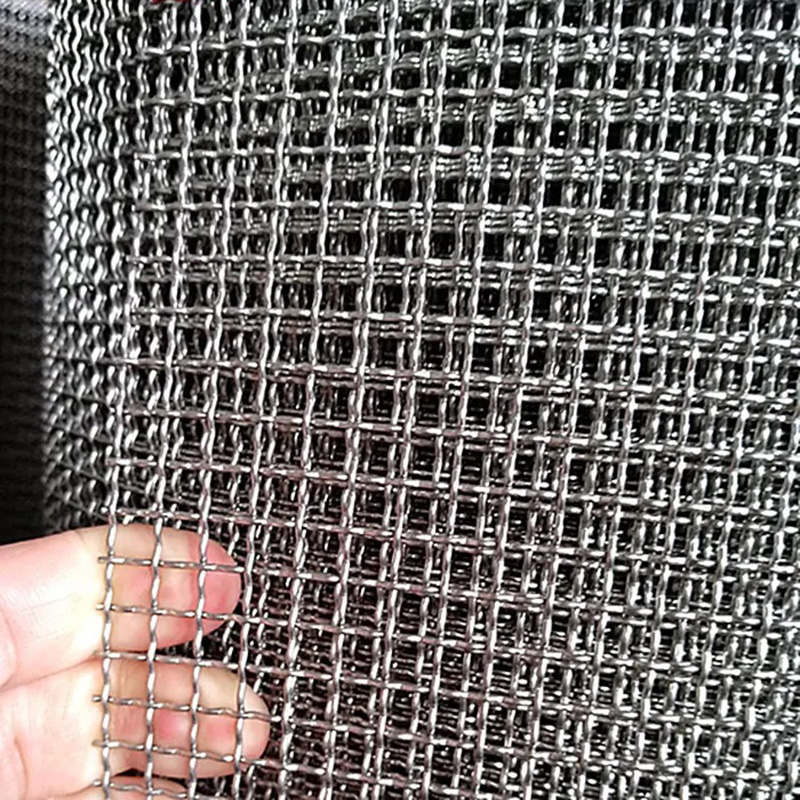

Galvanized binding wire has become an essential product in various industries due to its strength, durability, and resistance to corrosion. Manufacturers of galvanized binding wire play a crucial role in meeting the growing demand for this versatile wire type, which is widely used in construction, agriculture, and general applications.

Galvanization, the process of coating steel wire with a layer of zinc, enhances the wire's resistance to rust and deterioration. This characteristic makes galvanized binding wire an ideal choice for outdoor and high-moisture environments. As industries continue to expand and seek reliable materials, manufacturers focus on producing high-quality galvanized wire that meets diverse specifications and applications.

One of the primary sectors benefiting from galvanized binding wire is construction. Builders utilize this wire for tying rebar, fencing, and various structural elements. The wire’s tensile strength ensures that structures maintain integrity and stability, especially in regions prone to extreme weather conditions. Manufacturers understand the critical role their products play in construction safety, prompting them to maintain rigorous quality control processes.

In agriculture, galvanized binding wire is extensively used for securing plant stakes and trellis systems, providing necessary support to growing plants. Additionally, farmers find this wire useful for creating enclosures, repairing equipment, and managing livestock. The versatility of galvanized binding wire allows manufacturers to produce various gauges and lengths, catering to the specific needs of farmers and gardeners alike.

galvanized binding wire manufacturers

Moreover, galvanized binding wire manufacturers continuously innovate to improve their products. With advancements in technology, many manufacturers are adopting environmentally friendly practices, such as using sustainable materials and optimizing production processes to minimize waste. This shift not only benefits the planet but also enhances the manufacturers' reputability in an increasingly eco-conscious market.

Globalization has also influenced the galvanized binding wire manufacturing landscape. Manufacturers are now able to source raw materials and distribute their products worldwide, enabling them to reach diverse markets. This expansion opens up opportunities for collaboration and competition, pushing manufacturers to maintain high standards and adapt to changing consumer preferences.

In addition to quality and sustainability, customer service is another focal point for galvanized binding wire manufacturers. Building strong relationships with clients, providing timely deliveries, and offering technical support are crucial aspects of maintaining a competitive edge. Manufacturers that prioritize these elements are better positioned to succeed in the crowded marketplace.

In conclusion, galvanized binding wire manufacturers are integral to various industries, offering products that are essential for construction, agriculture, and more. Their commitment to quality, sustainability, and customer service ensures that they remain valuable partners in the ever-evolving industrial landscape. As demand for reliable materials continues to grow, these manufacturers will play a pivotal role in shaping the future of construction and agricultural practices, contributing to innovations that enhance efficiency and environmental stewardship.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025