-

+86 15030157877

-

sales@galvanizedmetalmesh.com

paź . 21, 2024 20:15 Back to list

Galvanized Steel Grating Manufacturers and Their Key Advantages in Construction Industry

Galvanized Steel Grating Factories An Overview of Production and Applications

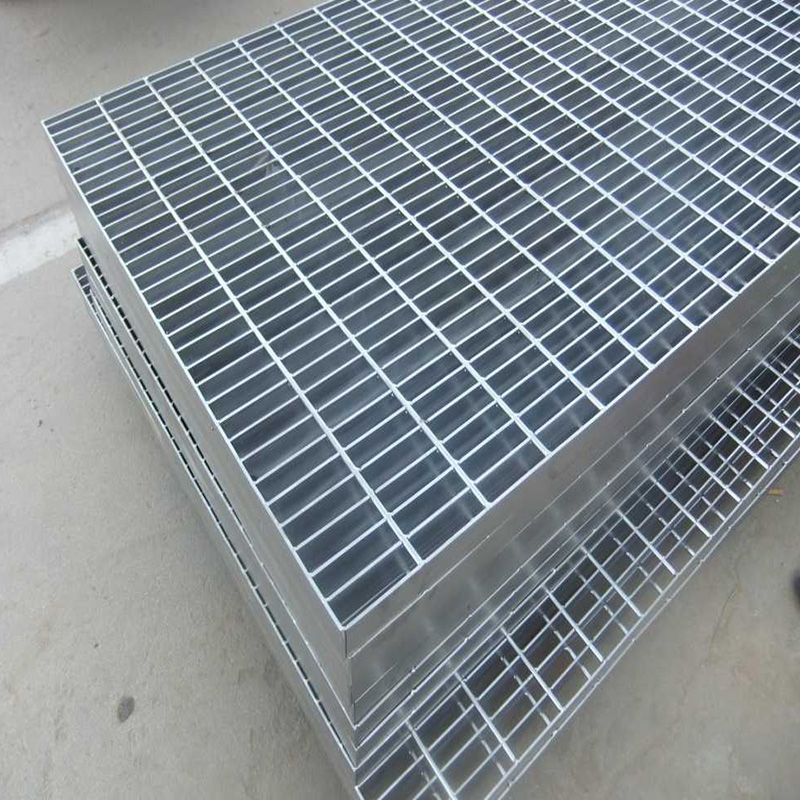

Galvanized steel grating has become an essential component in a wide range of industrial and commercial applications. Renowned for its strength, durability, and corrosion resistance, galvanized steel grating is extensively used in constructing walkways, platforms, and drainage systems. This article explores the significance of galvanized steel grating factories, their production processes, and their varied applications.

Understanding Galvanized Steel Grating

Galvanized steel grating is produced through a hot-dip galvanizing process, where steel is coated with a layer of zinc to prevent rust and corrosion. This treatment enhances the lifespan of the grating, making it an ideal choice for environments that are exposed to moisture or harsh chemicals. The grating itself is typically made from steel bars that are welded together to form a sturdy framework, providing strength and stability while allowing water, air, and light to pass through.

Production Process in Galvanized Steel Grating Factories

The production process in galvanized steel grating factories involves several key steps

1. Material Selection Quality control begins with selecting high-grade steel, which ensures the final product meets industry standards for strength and durability.

2. Fabrication The steel bars are cut to specific lengths and welded together, following the design specifications. Factories often use automated machinery to ensure precision and reduce production time.

3. Hot-Dip Galvanization The fabricated steel grating is immersed in a bath of molten zinc, coating the steel surface uniformly. This dip not only protects the steel from corrosion but also enhances its aesthetic appeal with a shiny finish.

4. Quality Inspection Once galvanized, the grating undergoes rigorous quality checks. Factories assess the consistency of the zinc coating and look for any defects in the grating structure.

galvanized steel grating factories

5. Packaging and Shipping After passing inspection, the grating is packaged for shipment. Factories often offer custom sizes and designs based on specific customer requirements, making their products suitable for various projects.

Applications of Galvanized Steel Grating

The versatility of galvanized steel grating finds it suitable for numerous applications across different sectors

- Industrial Uses In manufacturing plants, galvanized steel grating is commonly used for flooring, platform walkways, and machine guarding. Its slip-resistant surface ensures worker safety in busy environments.

- Architectural Applications In commercial buildings, it serves as decorative elements, such as balustrades and stair treads, while also providing structural support.

- Municipal Projects Galvanized steel grating is widely used in public infrastructure, including pedestrian walkways, bridges, and drainage covers. Its corrosion resistance is particularly valuable in urban environments where exposure to water is frequent.

- Wastewater Treatment Facilities In these facilities, the grating is crucial for supporting equipment while allowing for the efficient flow of wastewater. The chemical resistance of galvanized steel makes it an optimal choice for challenging conditions.

Conclusion

Galvanized steel grating factories play a vital role in the production of a material that meets the demands of modern infrastructure and industrial projects. With its long-lasting durability and low maintenance requirements, galvanized steel grating is an economical solution for a variety of applications. As industries continue to grow and evolve, the importance of high-quality galvanized steel grating will only increase, making these factories a key player in advancing construction and manufacturing methodologies. By understanding the production processes and diverse applications, stakeholders can better appreciate the value of galvanized steel grating in enhancing efficiency, safety, and sustainability in their respective fields.

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025