-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 03, 2024 16:50 Back to list

high quality perforated steel sheet

The Versatility and Importance of High-Quality Perforated Steel Sheets

In today's modern manufacturing and construction landscapes, high-quality perforated steel sheets play a pivotal role across a variety of applications. These sheets are not only valued for their structural integrity but also for their aesthetic appeal and functional versatility. With a wide range of hole patterns, sizes, and materials, perforated steel sheets serve fundamental functions in numerous sectors, including architecture, HVAC, automotive, and industrial equipment.

Understanding Perforated Steel Sheets

Perforated steel sheets are flat products made from metal panels that have been punched or stamped with holes or slots in various sizes and configurations. The perforation process offers numerous benefits, including weight reduction while maintaining strength, ensuring that these sheets are both lightweight and durable. Typically made from mild steel or stainless steel, perforated sheets can be tailored to meet specific requirements, whether they are used in structural applications or as decorative elements.

Applications of High-Quality Perforated Steel Sheets

1. Architectural Design In architecture, perforated steel sheets are often used for both functional and aesthetic purposes. Architects utilize these sheets to create visually striking façades, canopies, and partitions that provide ventilation while still offering a level of privacy. The ability to customize hole sizes and patterns allows for creative designs that enhance the building’s overall appeal.

2. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, high-quality perforated sheets are essential for effective airflow and sound management. These sheets are incorporated into diffusers and grills to ensure uniform distribution of air within a space, providing both comfort and efficiency. Their perforations allow for high air flow rates, making them ideal for all types of HVAC installations.

3. Industrial Applications Perforated steel sheets are widely used in various industrial applications, including the manufacturing of equipment guards, safety barriers, and conveyor systems. Their strength and durability ensure that they can withstand rigorous operational conditions, protecting both machinery and workers. Additionally, the lightweight nature of perforated sheets allows for easier installation and maintenance.

high quality perforated steel sheet

4. Automotive Industry The automotive sector also benefits from the use of perforated sheets, particularly in exhaust systems, grilles, and body panels. The ability to reduce weight without sacrificing strength is crucial in modern vehicle design, contributing to improved fuel efficiency and performance.

5. Filtering and Screening Perforated steel sheets are ideal for filtering and screening applications in various environments, from mining to food processing. Their customizable hole sizes allow for efficient sorting and separation of materials, ensuring that processes run smoothly and increase productivity.

Advantages of Using High-Quality Perforated Steel Sheets

The advantages of high-quality perforated steel sheets extend beyond their immediate applications. One of the primary benefits is their enhanced durability and resistance to corrosion, particularly when utilizing stainless steel varieties. This longevity translates to lower maintenance costs and extended service life, making them a cost-effective choice in the long run.

Another advantage is their efficiency in both energy use and material conservation. Perforated sheets can provide significant savings in energy costs when used in HVAC systems, as they promote better airflow and reduce the workload on heating and cooling units. Moreover, the nature of perforation allows for the reduction of material without compromising strength, leading to resource efficiency.

Lastly, the customization options available for perforated sheets enable manufacturers and designers to tailor their products to meet specific standards and desires, be it for performance or aesthetics. As more industries turn toward sustainable practices, the adaptability of perforated sheets positions them as a favorable choice for future developments.

Conclusion

High-quality perforated steel sheets play an integral role in diverse industries, providing essential structural support, aesthetic appeal, and efficient airflow. Their versatility makes them suitable for a vast array of applications, alongside benefits such as durability and customization. As technology advances and industries evolve, the demand for high-quality perforated steel sheets will undoubtedly continue to grow, solidifying their position as a crucial component in both functional and design-oriented projects.

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

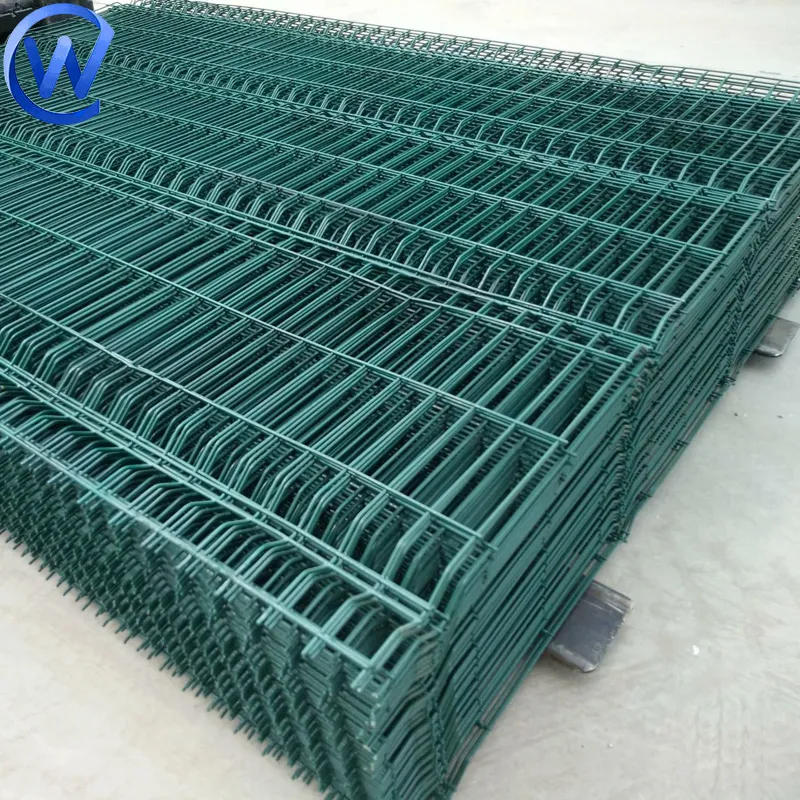

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025