-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 31, 2024 19:28 Back to list

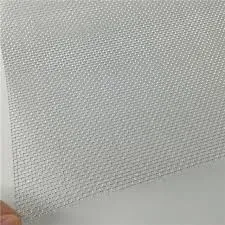

Durable Sand Screen Mesh for Enhanced Filtration and Performance in Construction Applications

The Importance of High-Quality Sand Screen Mesh in Industrial Applications

In many industries, the need for efficient and reliable filtration systems is paramount. One of the most crucial components in these systems is the sand screen mesh, which plays a vital role in the separation and filtration processes. High-quality sand screen mesh is essential for ensuring optimal performance, longevity, and operational efficiency in applications such as oil and gas, water treatment, and mining. This article will explore the significance of high-quality sand screen mesh, its construction materials, and its applications across various industries.

Understanding Sand Screen Mesh

Sand screen mesh is a type of filtering material used to separate sand and debris from fluids. It is commonly made using woven wire cloth, synthetic fibers, or a combination of both, and comes in various mesh sizes depending on the intended application. The mesh's primary purpose is to allow the passage of liquids while effectively retaining solid particles, ensuring a smooth and efficient flow of resources.

The Benefits of High-Quality Mesh

1. Enhanced Filtration Efficiency High-quality sand screen mesh is designed with precision, offering a uniform opening size that allows for optimal fluid flow and effective solid retention. This efficient filtration process reduces the risk of clogs and ensures the system operates at peak performance.

2. Durability and Longevity Industrial applications often expose sand screen mesh to harsh conditions, including high pressures, extreme temperatures, and corrosive materials. High-quality materials such as stainless steel and specialized polymers are resistant to wear and corrosion, providing a longer lifespan and reduced maintenance costs.

3. Cost-Effectiveness Although high-quality sand screen mesh may have a higher initial cost compared to lower-grade alternatives, the benefits of durability and efficiency translate to cost savings in the long run. Reduced downtime, fewer replacements, and lower maintenance needs lead to a more efficient operation overall.

high quality sand screen mesh

4. Customization Options Quality manufacturers often provide customization options for sand screen mesh, enabling businesses to select mesh sizes, materials, and designs tailored to their specific applications. This flexibility ensures that the filtration system meets the unique demands of various industries.

Applications in Different Industries

1. Oil and Gas Industry In oil and gas extraction, high-quality sand screen mesh is essential for separating sand and other particulates from crude oil and natural gas. This filtration process protects downstream equipment and enhances the efficiency of extraction processes, preventing costly damage and downtime.

2. Water Treatment Water treatment facilities rely heavily on sand screen mesh to remove sediments, algae, and other contaminants from water sources. High-quality mesh ensures that clean water is produced for public consumption and environmental protection, playing a crucial role in maintaining public health.

3. Mining Operations In the mining industry, sand screen mesh is used for material classification and separation of valuable minerals from waste material. The durability and reliability of high-quality mesh are essential in harsh mining environments, where mechanical failure can lead to significant financial losses.

4. Construction In construction projects, sand screen mesh is often used to filter aggregates and other materials for concrete production. High-quality mesh ensures that the materials used are clean and free from unwanted particles, which is critical for maintaining the structural integrity of buildings and infrastructure.

Conclusion

High-quality sand screen mesh is a vital component in various industrial applications, providing efficient filtration, durability, and customization options tailored to specific needs. Investing in quality mesh not only enhances operational efficiency but also contributes to cost savings by reducing maintenance and downtime. As industries continue to evolve and face new challenges, the demand for reliable and effective filtration solutions will only grow, underscoring the importance of high-quality sand screen mesh. By choosing the right mesh, businesses can ensure their systems operate smoothly, efficiently, and sustainably for years to come.

-

Spiral Plant Stick for Tomato Support - Durable & Easy to Install

NewsJul.27,2025

-

Stainless Steel Wire Mesh Roll Wholesale & Manufacturers – Quality Exporters

NewsJul.26,2025

-

High Quality 3D Curved Welded Wire Mesh Fence for Security and Aesthetics

NewsJul.25,2025

-

High-Quality Security Window Screen Mesh for Home & Office Protection

NewsJul.24,2025

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025