-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 10, 2024 08:46 Back to list

Iron Wire Mesh Manufacturing Solutions for Industrial and Commercial Applications

Exploring the Iron Mesh Factory A Key Player in Modern Manufacturing

In the realm of industrial manufacturing, few components are as versatile and essential as iron mesh. Its applications range from construction to agriculture, security, and even artistic endeavors. With the growing demand for durable and reliable materials, iron mesh factories have become critical players in meeting these needs. This article explores the operational dynamics of an iron mesh factory, its production processes, applications, and the impact it has on various industries.

The Significance of Iron Mesh

Iron mesh, often constructed from high-quality iron wires, is known for its strength, durability, and malleability. It serves multiple purposes, including serving as fencing, reinforcement in concrete structures, and filtration in agricultural settings. The versatility of iron mesh allows it to be crafted into various designs, accommodating different industrial standards and client specifications. Its importance is underscored by the fact that it not only aids in functional applications but also contributes aesthetically in architectural designs.

The Manufacturing Process

The process of manufacturing iron mesh begins with the selection of high-grade iron wires. These wires undergo several steps to prepare them for mesh formation. One of the initial stages involves drawing the iron into thinner wires. This is typically done through a drawn wire process, which enhances the tensile strength of the iron.

Once the wires are prepared, they are woven or welded together to form the mesh. The weaving process involves intertwining the wires in specific patterns, resulting in a mesh that is both strong and flexible. On the other hand, the welding process is more suitable for applications requiring extra rigidity and strength, where the wires are fused together at intersections. The choice between weaving and welding depends on the intended use of the mesh.

After production, the iron mesh undergoes various treatments to enhance its resistance to corrosion and environmental wear. These treatments can include galvanizing, where the mesh is coated with a layer of zinc, or applying a polymer finish. Such treatments significantly prolong the lifespan of the iron mesh, making it a cost-effective solution for consumers.

Applications of Iron Mesh

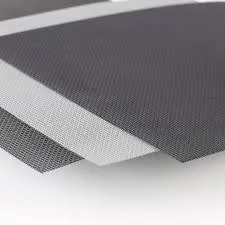

iron mesh factory

Iron mesh finds applications across a wide range of industries. In construction, it is predominantly used for reinforcing concrete structures, providing critical support to enhance structural integrity. The automotive industry also utilizes iron mesh in the production of filters and grilles, benefiting from its durability and strength.

In agriculture, iron mesh plays a vital role in creating protective barriers for crops, preventing animals from causing damage while allowing sunlight and air to reach the plants. Additionally, it is widely used in gardening for trellises and support systems for climbing plants.

Security is another major application of iron mesh. Whether in residential, commercial, or industrial settings, it serves as an effective fencing solution. Its robust nature deters unauthorized access while providing visibility and airflow. Furthermore, iron mesh is increasingly used in interior design, contributing to modern aesthetics in homes and corporate spaces.

The Future of Iron Mesh Factories

As sustainability and environmental concerns gain prominence in the manufacturing sector, iron mesh factories are adapting to these trends. Many manufacturers are exploring eco-friendly production techniques and materials that minimize waste and energy consumption. The introduction of advanced technologies, such as automation and robotics, is also streamlining production processes, enhancing efficiency, and reducing human error.

Moreover, the expansion of urbanization and infrastructure development globally signals a sustained demand for iron mesh products. This presents a considerable opportunity for iron mesh factories to innovate and expand their product offerings to meet evolving market needs.

Conclusion

Iron mesh factories play a crucial role in today’s manufacturing landscape, producing essential materials that serve various applications across multiple industries. From construction to agriculture and security, the significance of iron mesh is undeniable. As the industry continues to innovate and adapt to sustainable practices, it is poised to remain a vital pillar in enhancing the functionality and efficiency of modern infrastructure. In recognizing the importance of these factories, we can appreciate the foundational role they play in building our world.

-

Hexagonal Gabion for River Bank Protection and Retaining Walls

NewsJul.23,2025

-

Chain Link Fence-HEBEI WEICHUN WIRE MESH TRADE CO.,LTD.|durable fencing solutions&secure perimeter protection

NewsJul.23,2025

-

High Quality Stainless Steel Wire Mesh Roll & Supplier Wholesale Price

NewsJul.22,2025

-

Hexagonal Gabion Mesh: Durable Stone Cages for Landscaping

NewsJul.22,2025

-

Premium Black Brick Welded Mesh - High Strength & Corrosion Resistant

NewsJul.21,2025

-

High-Quality Chicken Wire Panels Leading Manufacturer & Exporter

NewsJul.08,2025