-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 23, 2024 13:02 Back to list

perforated metal panel factories

The Rise of Perforated Metal Panel Factories

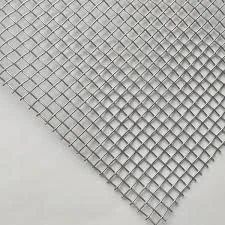

In modern architecture and design, the use of perforated metal panels has gained widespread acclaim for their versatility and aesthetic appeal. These panels, characterized by their unique patterns of holes or openings, serve a multitude of purposes, including enhancing aesthetics, improving acoustics, and allowing for ventilation and natural lighting. As the demand for these innovative materials grows, perforated metal panel factories are emerging as key players in the construction and design industries.

What are Perforated Metal Panels?

Perforated metal panels are sheets of metal that have been punctured with a variety of hole patterns, providing designers with a vast canvas to work from. They are made from durable materials such as aluminum, stainless steel, and carbon steel, allowing them to be used in various applications, from façade cladding to interior wall partitions. The customizable nature of these panels means that they can be tailored to meet specific design requirements, making them a desirable choice for architects and builders alike.

Applications of Perforated Metal Panels

The applications of perforated metal panels are extensive. In the architectural realm, they are often used for building facades, offering both functional and decorative benefits. The perforations can create stunning visual effects, allowing light to filter through while providing privacy and shade. This feature is particularly advantageous in urban areas where buildings are in close proximity to one another.

Additionally, perforated metal panels are increasingly being utilized in interior design. They can be employed in acoustic panels to absorb sound, making them ideal for offices, concert halls, and other spaces where noise control is necessary. Their lightweight nature and robust durability also make them suitable for creating room dividers or decorative wall elements, adding style and sophistication to any space.

The Process of Manufacturing Perforated Metal Panels

perforated metal panel factories

The production of perforated metal panels involves several key processes. Initially, sheets of metal are selected based on the desired strength, weight, and appearance. Next, the chosen metal is subjected to perforation, where machines create precise holes according to specified designs. This process can include various techniques such as laser cutting, punching, or water jet cutting, each offering different advantages in terms of speed, precision, and the complexity of designs.

After perforation, the panels undergo finishing treatments. These treatments can include powder coating, painting, or anodizing, which not only enhance the aesthetic value of the panels but also provide additional protection against corrosion and environmental wear. The result is a final product that is both visually appealing and durable, suitable for diverse applications.

The Benefits of Using Perforated Metal Panels

Choosing perforated metal panels for construction projects comes with numerous benefits. One major advantage is their sustainability. Many metal panels are recyclable, which aligns with the growing trend towards green building practices. Their ability to reduce heat gain and promote natural airflow can also contribute to energy efficiency in buildings, reducing reliance on artificial heating and cooling systems.

Moreover, the aesthetic versatility of perforated metal panels enables architects to explore innovative designs that enhance the overall architecture of a structure. The patterns and configurations can be customized to reflect the brand identity of businesses or cultural significance in public buildings.

Conclusion

As the world gravitates towards modern designs that embrace both functionality and aesthetics, perforated metal panel factories are poised to play a critical role in shaping the future of architecture. Their ability to blend style with sustainability ensures that perforated metal panels will remain a popular choice among architects, builders, and designers for years to come. By exploring the potential of these innovative materials, we can look forward to a built environment that not only meets practical needs but also inspires creativity and beauty in our urban landscapes.

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Smart AI Fence Solutions with GPT-4 Turbo | Secure & Fast

NewsAug.02,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025