-

+86 15030157877

-

sales@galvanizedmetalmesh.com

wrz . 28, 2024 07:19 Back to list

Poultry Mesh Production Facilities and Their Role in the Agriculture Industry

Understanding Poultry Mesh Factories An Overview

Poultry mesh factories play a crucial role in the poultry industry, providing essential materials for housing and protecting birds. Poultry farming has evolved over the years, and with it, the demand for reliable and durable materials has increased. Among these materials, poultry mesh—often made from wire or plastic—is vital for creating enclosures that keep birds safe from predators while allowing for adequate ventilation and visibility.

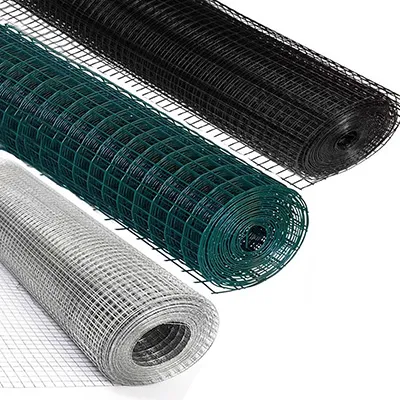

Poultry mesh comes in various types and sizes, made to accommodate different species and farming methods. A typical poultry mesh factory produces a range of products, including chicken wire, rabbit fencing, and specialized mesh for aviaries. The manufacturing process typically involves drawing wire into thin strands, weaving them into a mesh pattern, and then treating them to resist corrosion and wear from natural elements.

One of the primary benefits of using poultry mesh is the protection it offers. Predators such as raccoons, foxes, and birds of prey can pose significant threats to poultry populations. A well-constructed poultry enclosure using strong mesh helps mitigate these risks. Furthermore, poultry mesh allows for air circulation, which is essential for maintaining a healthy environment for the birds. Proper airflow helps to reduce humidity, control temperature, and minimize the risk of respiratory issues in poultry.

poultry mesh factories

Recent advancements in technology have greatly improved the production methods and materials used in poultry mesh factories. Modern factories often utilize automated machinery, which enhances efficiency and precision in manufacturing. Automation allows for larger production volumes while maintaining consistent quality. Additionally, innovations in material science have led to the development of stronger, lightweight, and weather-resistant meshes, further enhancing their performance in various climates.

In addition to manufacturing the mesh itself, many poultry mesh factories also offer customization services. Farmers may have specific requirements based on their operational scale, type of poultry, and environmental conditions. Custom sizes, colors, and mesh patterns can be produced to meet these diverse needs. This flexibility makes poultry mesh a versatile solution for both small-scale backyard farms and larger commercial operations.

Sustainability has also become an increasingly important focus for poultry mesh factories. Many producers are looking for ways to minimize their environmental impact by using recyclable materials and implementing eco-friendly manufacturing processes. The poultry industry itself is also working towards more sustainable practices, and collaborating with responsible manufacturers can help farmers align with these efforts.

In conclusion, poultry mesh factories are integral to the poultry industry, providing essential materials that support the safe and healthy rearing of birds. With advancements in technology, a focus on customization, and a commitment to sustainability, these factories are well-equipped to meet the evolving needs of modern poultry farming. As the industry continues to grow, the role of poultry mesh will undoubtedly remain significant, ensuring that both farmers and their flocks can thrive in a safe environment.

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025