-

+86 15030157877

-

sales@galvanizedmetalmesh.com

sie . 07, 2025 02:20 Back to list

Premium Perforated Metal Mesh & Custom Sheets

Unveiling the Versatility and Precision of Perforated Metal Mesh

In modern industrial and architectural applications, the demand for materials that combine durability, aesthetics, and functionality has never been higher. Among these, perforated metal mesh stands out as a highly versatile and indispensable material. From intricate architectural facades to robust industrial filtration systems, the unique properties of **perforated metal mesh** make it a preferred choice for a multitude of sectors. This comprehensive guide delves deep into the world of perforated metal, exploring its core characteristics, manufacturing intricacies, diverse applications, and the critical factors to consider when sourcing it.

Industry Trends and Market Dynamics for Perforated Metal Mesh

The global market for **perforated metal mesh** is experiencing steady growth, driven by expansion in the construction, automotive, and industrial sectors. According to a recent market analysis by Grand View Research, the global perforated metal market size was valued at USD 2.6 billion in 2022 and is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% from 2023 to 2030. This growth is largely fueled by increasing urbanization, infrastructure development, and the rising demand for lightweight, high-strength materials offering superior filtration and aesthetic appeal. Key trends include the growing adoption of stainless steel and aluminum for their corrosion resistance and longevity, as well as an increasing emphasis on custom solutions and sustainable manufacturing practices.

The market also sees a shift towards advanced manufacturing techniques, offering more precise and complex perforation patterns. This allows **perforated metal mesh** to meet stringent performance requirements in specialized applications such as acoustic management in buildings, EMI shielding in electronics, and fine filtration in chemical processing. As an essential component for various critical applications, the demand for reliable wholesale perforated metal mesh and custom perforated metal mesh continues to rise.

Understanding Key Technical Parameters and Specifications

The performance and suitability of perforated metal mesh sheet are defined by several critical technical parameters. Understanding these parameters is crucial for selecting the right product for your specific application. Here's a breakdown:

- Material Type: Common materials include Stainless Steel (304, 316, 316L), Carbon Steel, Galvanized Steel, Aluminum, Copper, Brass, and various alloys. The choice depends on environmental conditions, corrosion resistance needs, strength requirements, and budget. For instance, metal stainless steel perforated metal mesh is prized for its superior corrosion resistance.

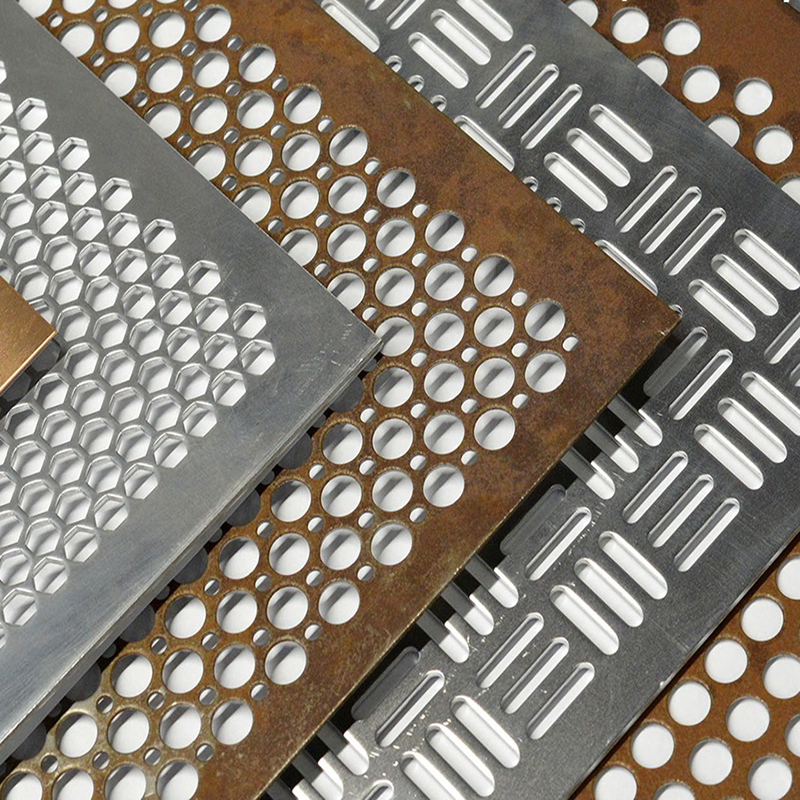

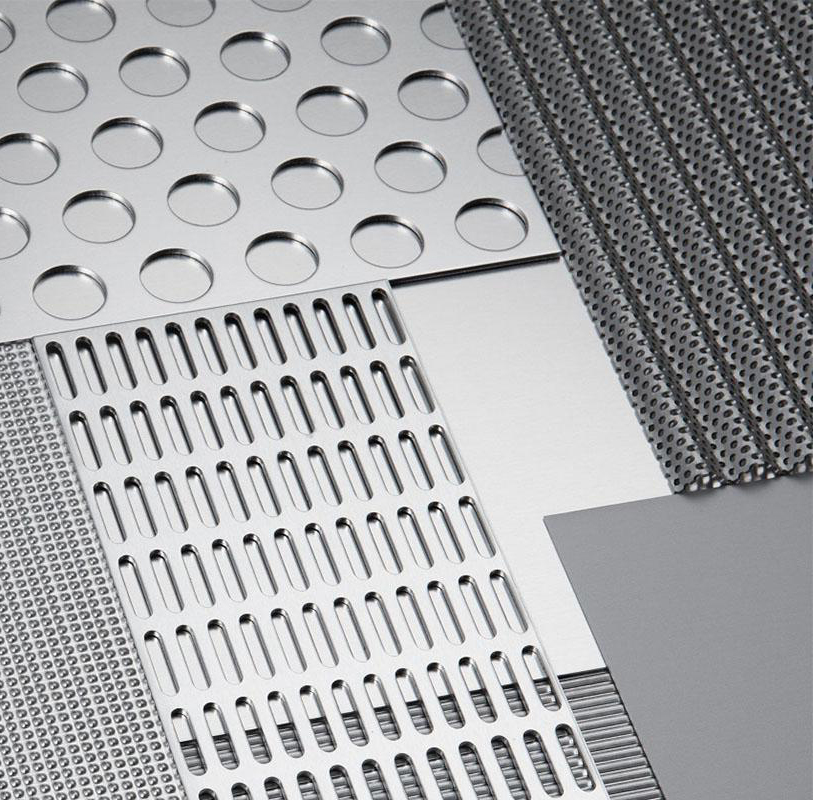

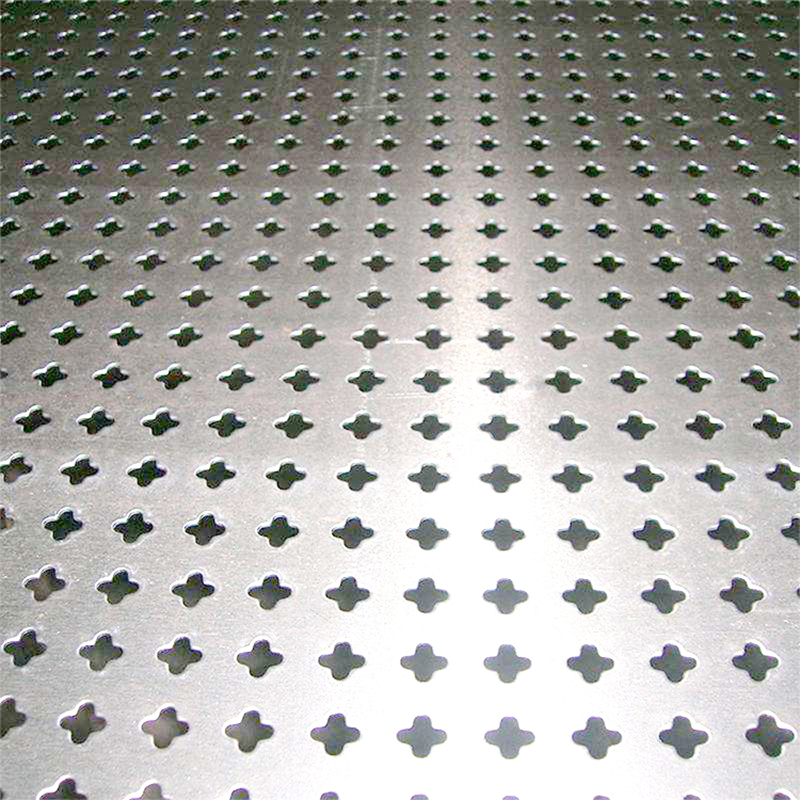

- Hole Shape: The most common shapes are round, square, slotted, hexagonal, and ornamental. Round holes offer the greatest strength and are widely used for filtration, while square holes provide larger open areas.

- Hole Size (Aperture): This refers to the diameter of a round hole or the side length of a square hole. Measured in millimeters or inches, it directly impacts filtration capabilities, light transmission, and airflow.

- Pitch: The distance from the center of one hole to the center of an adjacent hole. Pitch, along with hole size, determines the open area percentage. Common arrangements include staggered (60° or 45°) and straight row patterns.

- Thickness (Gauge): The thickness of the metal sheet before perforation. This affects the mesh's strength, rigidity, and weight.

- Open Area Percentage: The total area of the holes divided by the total area of the sheet, expressed as a percentage. This is a critical parameter for applications requiring specific airflow, light penetration, or liquid drainage. It typically ranges from 20% to 60%, though higher or lower percentages are possible.

- Margin/Unperforated Area: The solid, unperforated border around the edges of the sheet. Essential for mounting and structural integrity.

Common Perforated Metal Mesh Specifications Comparison Table

Below is a table illustrating common specifications for perforated metal mesh, highlighting the variability to suit different applications. Data points are representative of industry averages.

| Parameter | Common Range/Values | Typical Application | Notes |

|---|---|---|---|

| Material | Stainless Steel (304, 316), Carbon Steel, Aluminum, Galvanized Steel | General purpose, high corrosion, light weight, cost-effective | Stainless steel for corrosive environments (e.g., petrochemical) |

| Hole Shape | Round, Square, Slotted, Hexagonal | Filtration, architectural, aesthetic, ventilation | Round is most common for strength and versatility. |

| Hole Size (Diameter/Side) | 0.5 mm - 50 mm (0.02" - 2.0") | Fine filtration to heavy-duty screening | Smaller holes for finer filtration; larger for screening/guards. |

| Thickness (Gauge) | 0.5 mm - 10 mm (24 gauge - 0.375") | Lightweight panels to heavy-duty industrial grates | Thicker material for structural load bearing. |

| Pitch (Center to Center) | 1.5 mm - 75 mm (0.06" - 3.0") | Determines open area and pattern density | Crucial for uniform appearance and flow characteristics. |

| Open Area Percentage | 20% - 60% (common), up to 80% | Airflow, light diffusion, acoustic absorption, filtration | Higher open area means more flow/light, less strength. |

| Standard Sheet Sizes | 1m x 2m, 4ft x 8ft, 5ft x 10ft | Construction, industrial fabrication | Custom perforated metal mesh sheet sizes available. |

The Meticulous Manufacturing Process of Perforated Metal Mesh

The production of perforated metal mesh is a precise and highly automated process that transforms flat metal sheets into products with thousands of uniformly spaced holes. Unlike casting or forging, which are common for solid metal components, **perforated metal mesh** primarily utilizes punching or stamping, and sometimes laser cutting, for creating holes.

Detailed Manufacturing Process Flow:

Material Selection & Preparation:

The process begins with selecting the appropriate raw material, such as cold-rolled steel, galvanized steel, aluminum, or stainless steel coils/sheets. The material's grade (e.g., AISI 304 for metal stainless steel perforated metal mesh) is chosen based on the final product's intended application, considering factors like corrosion resistance, strength, and weldability. Sheets are typically uncoiled and flattened if starting from a coil.

Tooling Design & Setup:

Custom dies and punches are designed and manufactured to achieve the desired hole shape, size, and pattern (e.g., staggered 60° for round holes). Precision engineering ensures that the tools meet exact specifications, crucial for consistent hole quality and precise open area percentages. Tooling is set up in high-speed rotary punching presses or flat-bed presses.

Perforation (Punching/Stamping):

The prepared metal sheet is fed into the perforation machine. High-speed punches rapidly create the desired pattern of holes. Modern machines utilize CNC (Computer Numerical Control) technology, allowing for incredibly precise control over hole placement, consistency, and complex patterns. This process can create tens of thousands of holes per minute, ensuring efficient production for wholesale perforated metal mesh orders.

Flattening & Deburring:

After perforation, the sheet may exhibit some curvature or burrs around the edges of the holes due to the punching process. The sheet is then passed through a roller leveler or deburring machine to ensure it is perfectly flat and free of sharp edges. This step is critical for safety and aesthetic appeal.

Shearing/Cutting:

The continuous perforated sheet is then cut to the specified dimensions for final panels or rolls. Precision shearing machines ensure accurate lengths and widths, adhering to client's custom perforated metal mesh sheet requirements.

Finishing & Surface Treatment:

Depending on the application, the **perforated metal mesh** may undergo additional finishing processes. This can include powder coating for color and enhanced corrosion resistance, anodizing for aluminum, polishing for stainless steel, or painting. These treatments not only improve aesthetics but also extend the lifespan of the product, particularly in harsh environments like those in the petrochemical industry.

Quality Inspection & Packaging:

Throughout the entire manufacturing process, rigorous quality control checks are performed. This includes visual inspection for defects, dimensional checks (hole size, pitch, flatness), and material property verification. Adherence to international standards like ISO 9001, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) is paramount. Each batch of perforated metal mesh is then carefully packaged to prevent damage during transit, ready for delivery by perforated metal mesh exporters.

This streamlined process ensures high production efficiency while maintaining superior quality, making it possible for perforated metal mesh manufacturers to deliver consistent and reliable products globally.

Technical Advantages and Superior Performance

The widespread adoption of perforated metal mesh across various industries is a testament to its compelling technical advantages:

- Excellent Strength-to-Weight Ratio: By removing material strategically, **perforated metal mesh** maintains significant structural integrity while drastically reducing weight compared to solid sheets. This is crucial for applications where weight is a factor, such as transportation or architectural cladding, improving energy efficiency.

- Superior Ventilation and Airflow: The open area allows for unhindered air circulation, making it ideal for HVAC systems, machinery enclosures, and exhaust vents, contributing to better thermal management.

- Effective Filtration and Separation: Precise hole sizes enable exact screening, separation, and filtration of solids from liquids or gases. This is indispensable in petrochemical, mining, and food processing industries.

- Acoustic Dampening Properties: Perforated panels can significantly absorb sound, reducing noise pollution in industrial environments, concert halls, and office spaces. The holes act as resonators, dissipating sound energy.

- Aesthetic Versatility: Available in a vast array of patterns, finishes, and materials, perforated metal mesh offers architects and designers immense creative freedom, allowing for visually striking and unique facades, ceilings, and interior elements.

- Corrosion Resistance and Durability: When manufactured from materials like stainless steel (e.g., 316L perforated metal mesh) or with protective coatings (galvanizing, powder coating), the mesh exhibits exceptional resistance to corrosion, harsh chemicals, and extreme temperatures, ensuring a long service life, even in challenging environments like wastewater treatment.

- Security and Safety: Used for guards, barriers, and fencing, it provides security without completely obstructing visibility or airflow.

Diverse Application Scenarios and Industry Impact

The adaptability of perforated metal mesh makes it a cornerstone material in a vast range of industries:

- Architecture & Construction: Used for building facades, sunshades, balustrades, ceilings, wall panels, and decorative elements. Its aesthetic appeal combined with functional benefits like light diffusion and ventilation makes it highly sought after.

- Automotive & Transportation: Found in vehicle grilles, oil filters, exhaust components, engine screens, and interior trim for noise reduction and aesthetic purposes.

- Industrial & Manufacturing: Critical for machinery guards, screens, sorting equipment, drying trays, acoustic panels in factories, and structural components. Its durability and safety features are paramount here.

- HVAC & Environmental Control: Employed in air diffusers, vents, grilles, and filters, ensuring optimal airflow and air quality in buildings and industrial systems.

- Petrochemical & Chemical Processing: Essential for filtration, separation, and support grids in reactors, columns, and heat exchangers. Materials like 316L perforated metal mesh are vital for their extreme corrosion resistance against aggressive chemicals.

- Water Treatment & Metallurgy: Used in screens for water intake, filtration systems for wastewater treatment, and in mining for mineral separation, ensuring efficient and robust operations. Its anti-corrosion properties are crucial for longevity in these liquid-heavy environments.

- Agriculture: Applied in grain drying, seed sorting, animal enclosures, and pest control screens.

- Food & Beverage: Used in drying racks, sieves, and conveyor belts due to its hygienic properties and ease of cleaning, especially for stainless steel variants.

The ability of **perforated metal mesh** to offer solutions across such a broad spectrum underscores its importance as a key material in modern engineering and design.

Choosing the Right Partner: Manufacturers and Exporters Comparison

Selecting a reliable perforated metal mesh supplier or perforated metal mesh factory is paramount for ensuring quality, timely delivery, and competitive pricing. Here's what to consider when comparing `perforated metal mesh manufacturers` and `perforated metal mesh exporters`:

- Experience and Reputation: Look for manufacturers with a long-standing history (e.g., "over 20 years in the industry") and positive client testimonials. Established perforated metal mesh exporters often have a track record of successful international shipments.

- Quality Certifications: Verify adherence to international quality management standards like ISO 9001. This indicates a commitment to consistent quality control throughout the manufacturing process. Certifications for specific industries (e.g., ASTM for material standards) are also a strong indicator of reliability.

- Customization Capabilities: For unique projects, ensure the supplier can produce custom perforated metal mesh and custom perforated metal mesh sheet according to your precise specifications regarding hole size, pattern, material, and dimensions.

- Production Capacity & Lead Time: Evaluate their ability to handle large orders (e.g., wholesale perforated metal mesh sheet) and meet your required delivery schedules. A robust factory will have efficient processes to minimize lead times.

- Material Sourcing & Quality: Inquire about their raw material suppliers and their own internal material inspection processes. This ensures the integrity of the final product, especially for specialized materials like high-grade stainless steel.

- Customer Support & After-Sales Service: A good supplier offers excellent communication, technical support, and responsive after-sales service, including clear warranty policies.

- Pricing & Value: While cost is a factor, prioritize value over just the lowest price. A slightly higher price might reflect superior material quality, better manufacturing precision, and reliable service, leading to long-term savings.

Tailored Solutions: Custom Perforated Metal Mesh

While standard perforated metal mesh products cater to many needs, specific projects often require bespoke solutions. This is where custom perforated metal mesh shines. Manufacturers with advanced capabilities can produce mesh tailored to exact client specifications, offering unparalleled design flexibility. This includes:

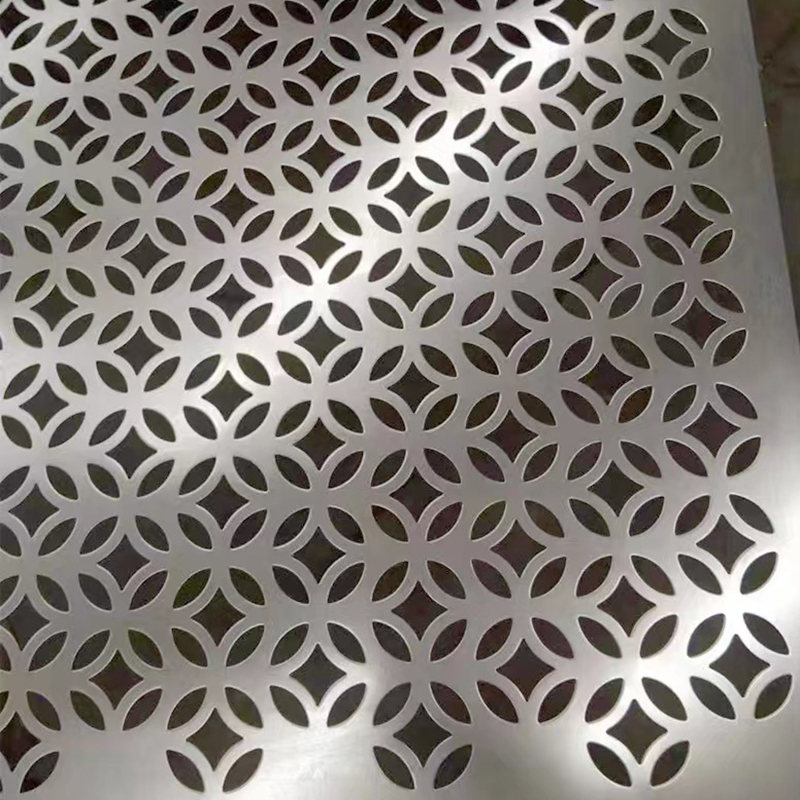

- Unique Hole Patterns: Beyond standard round or square, custom patterns can include intricate designs, logos, or variable hole sizes within a single sheet.

- Specific Material Grades: Sourcing specialized alloys for extreme environments, such as high-temperature applications or specific chemical resistance needs.

- Precision Fabrication: Cutting, bending, welding, and forming the perforated sheets into complex shapes or components, ready for installation.

- Custom Finishes: Applying specific coatings (e.g., anti-graffiti, specific RAL colors for architectural integration) or polishing levels.

- Edge Margins and Unperforated Areas: Tailoring these for specific mounting requirements or to integrate with other structural elements.

Engaging with a perforated metal mesh factory capable of extensive customization ensures that the final product perfectly aligns with project requirements, optimizing performance and aesthetics.

Application Case Studies & Client Successes

Our commitment to delivering high-quality perforated metal mesh is reflected in our successful partnerships across diverse industries. Here are a few illustrative examples:

- Architectural Façade in Urban Redevelopment: A prominent urban redevelopment project utilized our custom perforated metal mesh sheet (anodized aluminum with a hexagonal pattern) for building facades. The solution provided excellent sun shading, reduced energy consumption by 15% through optimized natural light, and created a distinctive visual identity for the complex. Client feedback highlighted the ease of installation and the stunning aesthetic outcome.

- Industrial Filtration System Upgrade: A major chemical plant required an upgrade to its filtration system for corrosive liquids. We supplied 316L metal stainless steel perforated metal mesh, engineered with precise slot perforations. This robust solution significantly improved filtration efficiency, reducing maintenance downtime by 25% and extending filter lifespan by 50% compared to previous materials. The client praised our technical expertise and quick turnaround.

- Acoustic Panels for a Concert Hall: For a new state-of-the-art concert hall, our **perforated metal mesh** panels were integrated into the ceiling and wall designs. Manufactured with specific open area percentages and backing materials, these panels achieved optimal acoustic absorption, dramatically enhancing sound clarity and audience experience. This project demonstrated the aesthetic and functional versatility of our products.

These cases exemplify how our perforated metal mesh solutions contribute to project success, embodying our extensive experience and commitment to client satisfaction.

Rigorous Quality Assurance and Industry Standards

At the core of a reliable perforated metal mesh supplier is an unwavering commitment to quality assurance. Our manufacturing processes adhere to stringent international standards, ensuring every product meets or exceeds performance expectations. Key aspects of our quality commitment include:

- ISO 9001 Certification: Our quality management system is certified to ISO 9001, guaranteeing consistency in production, from raw material sourcing to final inspection. This ensures that every wholesale perforated metal mesh sheet or custom order adheres to the highest global benchmarks.

- Adherence to ASTM & ANSI Standards: We rigorously follow ASTM standards for material specifications (e.g., ASTM A240 for stainless steel) and mechanical properties, and ANSI standards for dimensions and tolerances, providing documented proof of compliance.

- Advanced Testing Procedures: Each batch undergoes comprehensive testing, including:

- Dimensional Verification: Using precision calipers and optical scanners to ensure hole size, pitch, and sheet dimensions are within specified tolerances.

- Material Composition Analysis: Spectrometers are used to verify the chemical composition of raw materials, ensuring they match the specified grade (e.g., correct chromium and nickel content for 304 or 316 stainless steel).

- Tensile Strength & Hardness Testing: To confirm the mechanical strength and durability of the finished mesh.

- Corrosion Resistance Tests: For products intended for harsh environments, salt spray tests or specific chemical immersion tests are conducted to simulate real-world conditions and ensure long-term integrity, especially for metal stainless steel perforated metal mesh.

- Traceability: Every product batch is traceable back to its raw material origin and production parameters, allowing for complete transparency and accountability.

This meticulous approach to quality ensures an extended product lifespan, often exceeding 20-30 years in typical conditions, depending on material and environment. Our products come with a comprehensive warranty against manufacturing defects, providing our clients with complete peace of mind and demonstrating our trustworthiness as a leading perforated metal mesh supplier.

Frequently Asked Questions (FAQ) about Perforated Metal Mesh

Q1: What is the typical lifespan of perforated metal mesh?

A1: The lifespan largely depends on the material, environmental conditions, and application. High-quality stainless steel perforated metal mesh can last 20-50 years or even longer in non-corrosive environments. In demanding conditions like petrochemical or marine applications, 316L stainless steel or specialized coatings significantly enhance longevity. Proper maintenance also plays a key role.

Q2: How is the "open area percentage" calculated for perforated metal mesh?

A2: Open area percentage is calculated by dividing the total area of the holes by the total area of the sheet and multiplying by 100. For round holes arranged in a 60-degree staggered pattern, a common formula is: Open Area = (0.9069 x Hole Diameter²) / Pitch² x 100%. This metric is crucial for determining fluid flow, light transmission, and sound absorption capabilities.

Q3: Can perforated metal mesh be customized for specific applications?

A3: Absolutely. Most perforated metal mesh manufacturers offer extensive customization options, including specific hole shapes, sizes, patterns, materials, finishes (e.g., powder coating, anodizing), and fabricated forms (e.g., bending, welding, rolling). This allows for tailoring the mesh to precise aesthetic and functional requirements, making custom perforated metal mesh a significant part of the market.

Q4: What are the typical lead times for ordering wholesale perforated metal mesh?

A4: Lead times vary based on quantity, material availability, and complexity of customization. For standard wholesale perforated metal mesh sheet products, lead times can range from 1-3 weeks. For large or highly customized orders, it might extend to 4-8 weeks. It's always best to discuss your specific timeline with the perforated metal mesh supplier at the inquiry stage.

Q5: What inspection standards should a reliable perforated metal mesh factory adhere to?

A5: A reputable perforated metal mesh factory should adhere to international quality standards such as ISO 9001 for quality management. Additionally, compliance with material-specific standards like ASTM (American Society for Testing and Materials) for material composition and mechanical properties, and ANSI (American National Standards Institute) for dimensional tolerances, ensures product integrity and reliability.

Q6: How does perforated metal mesh contribute to energy efficiency in buildings?

A6: In architectural applications, **perforated metal mesh** can be used as sunshades or facades to manage solar heat gain, reducing the need for air conditioning. Its open area also facilitates natural ventilation, further minimizing reliance on mechanical cooling systems. This dual benefit contributes significantly to a building's overall energy efficiency and sustainability.

Q7: Is perforated metal mesh suitable for outdoor applications?

A7: Yes, many types of perforated metal mesh are highly suitable for outdoor use. Galvanized steel and metal stainless steel perforated metal mesh (especially 304 and 316 grades) are excellent choices due to their inherent corrosion resistance. Further protection can be achieved with powder coating or other surface treatments, ensuring durability against weather elements, UV radiation, and pollution.

Conclusion: The Enduring Value of Perforated Metal Mesh

From its intricate manufacturing process driven by precision CNC technology to its myriad applications spanning architecture, industry, and environmental control, perforated metal mesh truly embodies versatility and engineered excellence. Its unique combination of strength, ventilation, aesthetic appeal, and corrosion resistance makes it an invaluable material in modern design and construction. As perforated metal mesh manufacturers continue to innovate with new materials and advanced perforation techniques, its applications are only set to expand.

Whether you require wholesale perforated metal mesh for large-scale industrial projects or custom perforated metal mesh sheet for a bespoke architectural vision, selecting a reputable perforated metal mesh supplier with a strong commitment to quality and customer service is paramount. Our dedication to ISO-certified manufacturing, rigorous testing, and comprehensive client support ensures that you receive a product that not only meets but exceeds your expectations, delivering long-term performance and value. For more information or to discuss your specific project needs, please visit our product page: Perforated Metal Mesh.

References and Further Reading:

- Grand View Research: Perforated Metal Market Size, Share & Trends Analysis Report (Industry Market Research).

- ASTM International: Standards for Metals (Technical Standards Organization).

- ArchDaily: Perforated Metal in Architecture (Architectural Publication).

- Engineering ToolBox: Perforated Sheet Metal - Open Area (Engineering Resource).

This is the last article

-

Premium Perforated Metal Mesh & Custom Sheets

NewsAug.07,2025

-

Premium Security Window Screen Mesh | Unmatched Safety

NewsAug.05,2025

-

Premium Artificial Grass Fence | AI Design Privacy Solution

NewsAug.04,2025

-

Premium Hexagonal Gabion Mesh Solutions | Durable & Eco-Friendly

NewsAug.03,2025

-

Welded Gabion Solutions: Durable & AI-Enhanced Designs

NewsAug.01,2025

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025