-

+86 15030157877

-

sales@galvanizedmetalmesh.com

sie . 07, 2025 15:23 Powrót do listy

PVC coated barbed wire: a sturdy defense line for safety protection

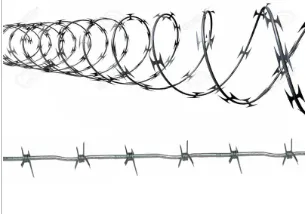

PVC coated barbed wire, with its unique design and excellent performance, has become a reliable barrier for safeguarding border security among various safety protection facilities. It perfectly combines the deterrent power of traditional barbed wire with the protective properties of PVC coating, playing an irreplaceable role in multiple fields such as industry, agriculture, and security.

The construction design of PVC coated barbed wire combines practicality and durability

The main body of the anti theft barbed wire fence is made of high-strength steel wire, which is woven into sharp and piercing structures through special processes, forming a strong physical barrier and psychological deterrence against illegal intruders. On this basis, the surface is uniformly covered with a layer of PVC coating, which is made of high-quality polyvinyl chloride material and attached through high-temperature hot-dip or electrostatic spraying processes. It not only gives the barbed wire a bright color, but also effectively isolates external corrosion factors. PVC coating has good weather resistance, which can maintain stability for a long time in extreme cold, heat, acid rain, and salt spray, greatly extending the service life of barbed wire.

The performance advantages of PVC coated barbed wire are outstanding in practical applications

From the perspective of protective performance, the sharp spike like structure can effectively prevent people and animals from crossing, and has a significant effect on ensuring regional safety; Single barbed wire has much higher corrosion resistance than ordinary barbed wire, and can still maintain structural integrity in humid coastal areas, saline alkali areas, or high corrosion environments such as chemical plants, reducing the cost of frequent replacement. In addition, PVC coating has good insulation properties, reducing the risk of electric shock caused by accidental contact, and reducing the noise generated by friction with metal, making it safer and quieter to use.

PVC coated bare wire has a wide range of application scenarios in various fields

In animal husbandry, galvanized steel concertina barbed wire can be used as a pasture fence, which can prevent livestock from getting lost and block the invasion of foreign wild animals; A tight protective net can be constructed around industrial parks and warehouses to prevent property theft; In special areas such as border security and military restricted zones, it has become a solid defense line for safeguarding national security and important facilities with strong deterrence and protection capabilities. Moreover, due to its convenient installation, it can be flexibly adjusted according to different terrains and protection needs. Whether it is flat grasslands, undulating mountains, or complex urban boundaries, an effective protection system can be quickly established.

With the upgrading of security protection requirements, PVC coated barbed wire is also constantly innovating and developing

The research and application of new materials have further improved the wear resistance and aging resistance of coatings; In terms of process, the popularization of automated weaving and coating technology has improved production efficiency and product quality stability; At the same time, in order to meet the aesthetic needs of different scenarios, the razor barbed wire mesh has a more diverse color selection, and some products also incorporate reflective materials to enhance the night warning effect, balancing practicality and aesthetics.

In summary, PVC coated barbed wire has become an important tool in the field of safety protection due to its scientific construction, excellent performance, and wide applicability. It safeguards the safety of various areas with sturdy protective capabilities, reduces maintenance costs with long-lasting durability, and meets diverse needs with flexible adaptability. In the future, with the continuous advancement of technology, PVC coated barbed wire will continue to innovate and break through in the field of safety protection, contributing greater strength to ensuring public safety and maintaining social stability with more advanced technology and more complete functions.

PVC coated barbed wire FAQs

What is the main purpose of PVC coated barbed wire?

Mainly used in the field of security protection, such as the top of walls in prisons, military bases, airports, industrial parks, etc., it has both physical barriers and deterrent effects. PVC coating provides rust prevention and aesthetic effects, suitable for long-term outdoor use.

What are the advantages of PVC coated barbed wire?

Corrosion prevention: isolate metal wires from contact with air and moisture to extend their service life;

Diverse colors: customizable in green, black, blue, and other colors to coordinate with the environment;

Reduce damage: Compared to ordinary barbed wire, PVC wrapped spikes have a smoother surface, reducing the risk of accidental scratches.

How long is the lifespan of PVC coated barbed wire?

Under normal outdoor conditions, the service life can reach 1015 years, depending on climate conditions (such as UV intensity, acid rain, etc.) and coating thickness (usually 0.30.6mm).

What issues should be noted when installing PVC coated bare wire?

It needs to be fixed with brackets or Y-shaped columns to maintain a tight state;

Prevent the coating from being scratched by hard objects during installation;

Suggest setting support points every 2030 meters to prevent sagging.

How to maintain PVC coated bare wire?

Regularly inspect the coating for cracking or peeling, and promptly repair any damaged areas; When cleaning, simply wipe with a soft cloth and avoid using strong acid or alkali cleaners. If there is local rust, it is necessary to remove the rust and apply PVC special repair paint.

-

Stainless Steel Wire Mesh | 304/316, Factory Direct Prices

AktualnościNov.17,2025

-

Stainless Steel Wire Mesh – Durable, Rust-Resistant, Exact

AktualnościNov.17,2025

-

Expanded Metal Mesh: Custom, Durable, Factory-Direct Supply

AktualnościNov.17,2025

-

Security Window Screen Mesh | Stainless Steel, Anti-Theft

AktualnościNov.17,2025

-

Anti Bird Spikes Exporter – Durable Humane OEM Wholesale

AktualnościNov.17,2025

-

Metal Mesh Fabric For Glass Laminated - UV-Stable, Custom

AktualnościNov.11,2025