-

+86 15030157877

-

sales@galvanizedmetalmesh.com

gru . 20, 2024 11:57 Back to list

PVC Coated Welded Wire Mesh Manufacturing Company Overview and Benefits

The Rise of PVC Welded Wire Mesh Factories Innovations and Applications

In recent years, the demand for various types of wire mesh has significantly increased due to its widespread applications in construction, agriculture, and industrial sectors. Among these, PVC welded wire mesh has gained remarkable popularity for its versatility, durability, and resistance to harsh environmental conditions. Consequently, the emergence of specialized PVC welded wire mesh factories has marked a pivotal moment in the manufacturing landscape.

PVC welded wire mesh is produced by welding together steel wires at their intersections, followed by a coating of polyvinyl chloride (PVC). This combination delivers a robust product that stands out for its anti-corrosive properties, making it an ideal choice for outdoor applications. The process of manufacturing PVC welded wire involves meticulous attention to detail, including the selection of high-quality steel wires that ensure strength and longevity.

The Rise of PVC Welded Wire Mesh Factories Innovations and Applications

Moreover, the agricultural sector has found PVC welded wire mesh to be indispensable. It is extensively used for creating protective barriers around crops, ensuring that animals do not cause damage. Additionally, farmers use these meshes for creating enclosures for livestock, which are not only secure but also easy to handle and maintain. The flexibility of the mesh allows for varied designs depending on the specific needs of the agricultural setup.

pvc welded wire mesh factory

The innovation brought about by PVC welded wire mesh factories has not only boosted production capabilities but also improved product quality. These modern facilities utilize advanced machinery and technology that streamline the manufacturing process while enhancing the precision of the welds. Automation has played a crucial role in minimizing human error, ensuring that each mesh product meets the highest standards of quality and reliability. Furthermore, many factories have adopted eco-friendly practices, such as recycling the waste generated during the production process, contributing to sustainable manufacturing.

Another noteworthy aspect of PVC welded wire mesh factories is their commitment to customer satisfaction. With the rise of e-commerce and online marketplaces, many manufacturers have adapted to provide customized solutions tailored to specific client needs. By offering various dimensions, wire thicknesses, and colors, these factories can cater to diverse markets, ensuring that clients receive products perfectly suited for their applications.

As the world continues to evolve and face new challenges, including those related to environmental sustainability, the PVC welded wire mesh industry is well-positioned to adapt and thrive. The combination of durability, versatility, and affordability makes PVC welded wire mesh an essential product across different sectors.

In conclusion, the growth of PVC welded wire mesh factories signifies a broader trend of innovation within manufacturing industries. Their impact spans multiple applications, reinforcing the importance of adaptability and quality in product development. As modern challenges arise, PVC welded wire mesh not only stands as a testament to engineering excellence but also as a versatile solution for a variety of practical needs. The journey of these factories is just beginning, and their future holds exciting prospects for both manufacturers and consumers alike.

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

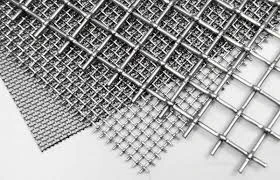

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

Hexagonal Gabion for Slope Protection & Retaining Walls | Durable Wire Mesh

NewsJul.29,2025