-

+86 15030157877

-

sales@galvanizedmetalmesh.com

paź . 31, 2024 12:38 Back to list

4x4 Square Wire Panels for Quality Construction and Security Solutions

The Versatility of Square Wire Panels A Focus on 4x4 Factory Options

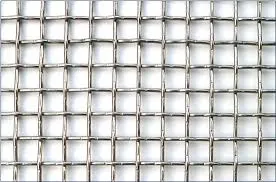

Square wire panels have become increasingly popular across various industries due to their robust construction and versatility. At the heart of this trend is the 4x4 factory square wire panel, a versatile solution that caters to numerous applications including fencing, animal enclosures, construction, and even decorative purposes. This article delves into the benefits, applications, and manufacturing process of these panels, highlighting why they are a preferred choice for many.

Benefits of Square Wire Panels

One of the primary advantages of 4x4 square wire panels is their strength and durability. Made from high-quality steel wire, these panels can withstand significant pressure and environmental challenges. Their square shape not only enhances aesthetic appeal but also ensures uniformity and reliability in strength distribution, making them a dependable choice for projects requiring tight security and resilience.

Furthermore, the mesh design allows for adequate airflow and visibility, making them suitable for agricultural applications, such as creating livestock enclosures or garden fencing. The 4x4 spacing of the wire is ideal for preventing animals from escaping while still allowing owners to keep an eye on their animals or crops.

Applications Across Industries

Square wire panels are commonly used in agriculture, construction, and security. In agriculture, the 4x4 panels serve as effective fencing solutions for farms, gardens, and pastures. They keep livestock in while preventing predators from entering, promoting a secure environment for farming operations.

square wire panel 4x4 factory

In construction, these panels find use in a range of applications, such as reinforcing concrete structures and forming temporary barriers at construction sites. Their durability makes them ideal for heavy-duty applications where safety and structural integrity are paramount.

In security contexts, organizations use square wire panels to create perimeter fencing for warehouses, factories, and residential areas. The strong, interwoven wire structure provides a deterrent against intruders while maintaining visibility for monitoring purposes.

Manufacturing Process

The manufacturing process of 4x4 square wire panels involves several steps to ensure high quality and durability. The process begins with selecting high-grade steel wire, which is then cut to the desired length. The wire is woven together in a square pattern, achieving the characteristic 4x4 spacing.

Following weaving, the panels undergo a galvanization process to protect against rust and corrosion, extending the product's lifespan even when exposed to harsh weather conditions. Quality control measures are implemented at every stage of production to ensure that the final product meets industry standards and customer expectations.

Conclusion

The 4x4 square wire panel stands out as a versatile, durable, and practical solution suited for an array of applications. Its strength, combined with its various uses in agriculture, construction, and security, makes it a popular choice among manufacturers and consumers alike. As industries continue to seek reliable fencing and structural solutions, the demand for square wire panels will likely keep growing. Investing in high-quality square wire panels from reputable manufacturers ensures that users benefit from longevity, strength, and aesthetic appeal, making them an essential component for a variety of projects.

-

Premium Welded Gabion Mesh | Robust & Eco-Friendly

NewsJul.31,2025

-

Premium Eco-Friendly Roof Tiles | Affordable & Durable

NewsJul.31,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.30,2025

-

High-Quality Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025

-

High Quality Square Wire Mesh Manufacturer & Supplier for Wholesale

NewsJul.29,2025

-

Premium Roof Tiles for Durable & Stylish Roofing Solutions

NewsJul.29,2025